High-performance double-tail-end pumping single-doped Ho:YAG solid laser

A solid-state laser, pump laser technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as unbalanced crystal thermal distribution, and achieve compact structure, balanced thermal distribution, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

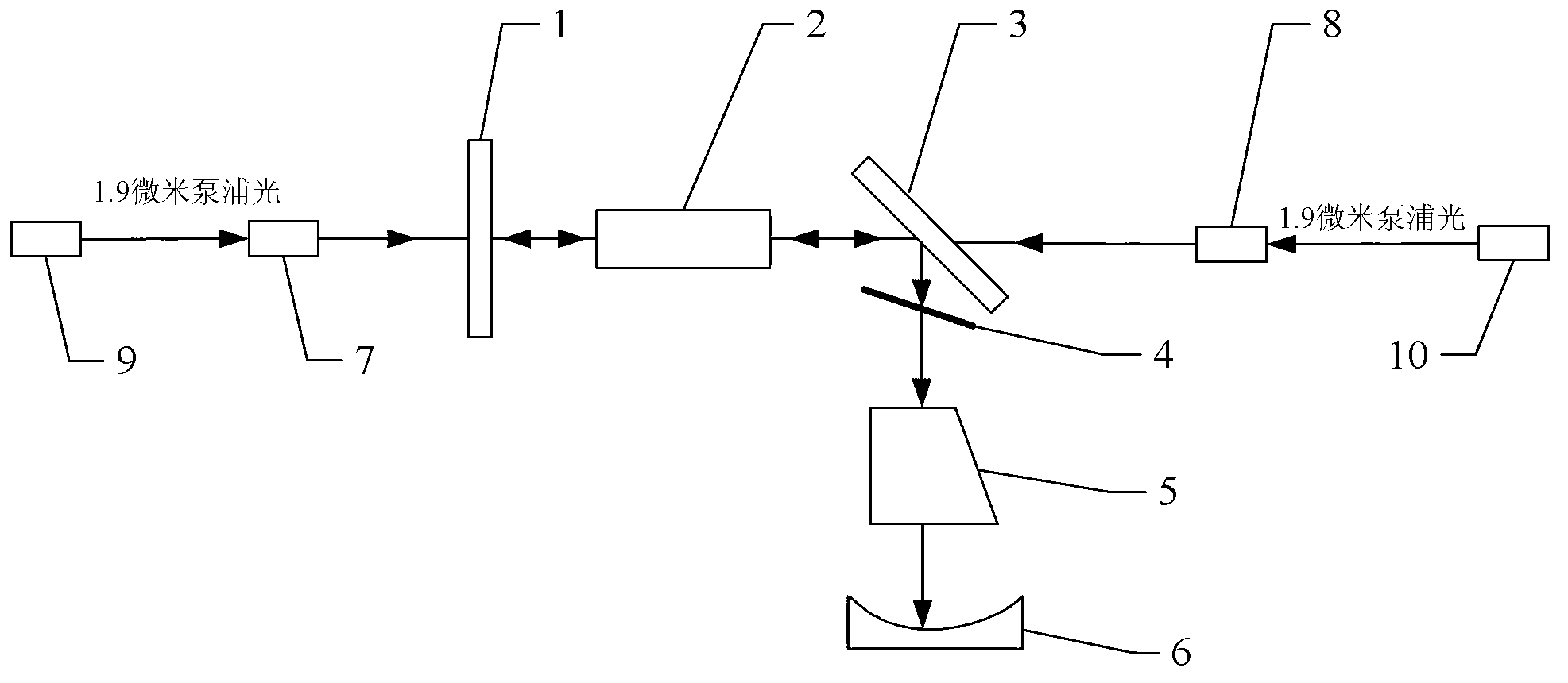

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment mode, the high-performance dual-end pump single-doped Ho:YAG solid-state laser described in this embodiment mode, it comprises the first total reflection mirror 1, single-doped Ho:YAG crystal 2, the second total reflection mirror 3, F-P etalon 4, 2 μm output coupling mirror 6, first isolation device 7, second isolation device 8, first pump laser 9 and second pump laser 10;

[0012] The 1.9 μm pumping light emitted by the first pump laser 9 is incident on the first isolating device 7, and the pumping light transmitted through the first isolating device 7 is incident on the first total reflection mirror 1, and the pump light transmitted through the first total reflection mirror 1 The pump light is incident on the single-doped Ho:YAG crystal 2, and after being absorbed by the single-doped Ho:YAG crystal 2, a 2 μm laser is generated, and the 2 μm laser is incident on the second total reflection mirr...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment is a further limitation of the high-performance dual-end pumped single-doped Ho:YAG solid-state laser described in Embodiment 1.

[0016] It also includes a Q-switching crystal 5 which is connected in series in the optical path between the F-P etalon 4 and the 2 μm output coupling mirror 6 .

[0017] The pumping method is double-end pumping, and the two pumping lights must first pass through an isolation device and then be injected into the single-doped Ho:YAG crystal 2 . The pump light is incident from the 0°2μm total reflection mirror and the 45°2μm total reflection mirror respectively. The laser resonator consists of the first total reflection mirror 1, the second total reflection mirror 3 and the 2μm output coupling mirror 6 arranged in an "L" shape, and each pumping optical path is inserted into an isolation device. The 2 μm single-wavelength laser output is obtained by tuning the angle of the F-P etalon 4.

[0018] In this embodimen...

specific Embodiment approach 3

[0019] Specific embodiment three: this embodiment is a further limitation of the high-performance dual-end pumped single-doped Ho:YAG solid-state laser described in specific embodiment one or two,

[0020] The first total reflection mirror 1 is a 2 μm total reflection mirror with a critical angle of 0°,

[0021] The 2 μm laser light transmitted through the single-doped Ho:YAG crystal 2 is vertically incident on the first total reflection mirror 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com