System and method for remote control, upgrading and standardization of electric vehicle

An electric vehicle, remote monitoring technology, applied in the transmission system, program control device, vehicle components, etc., can solve the problems of inability to upgrade the vehicle, inability to upgrade the remote software system of the vehicle, inability to realize online upgrade of the software system and online support from experts, etc. To achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below with reference to the accompanying drawings and embodiments.

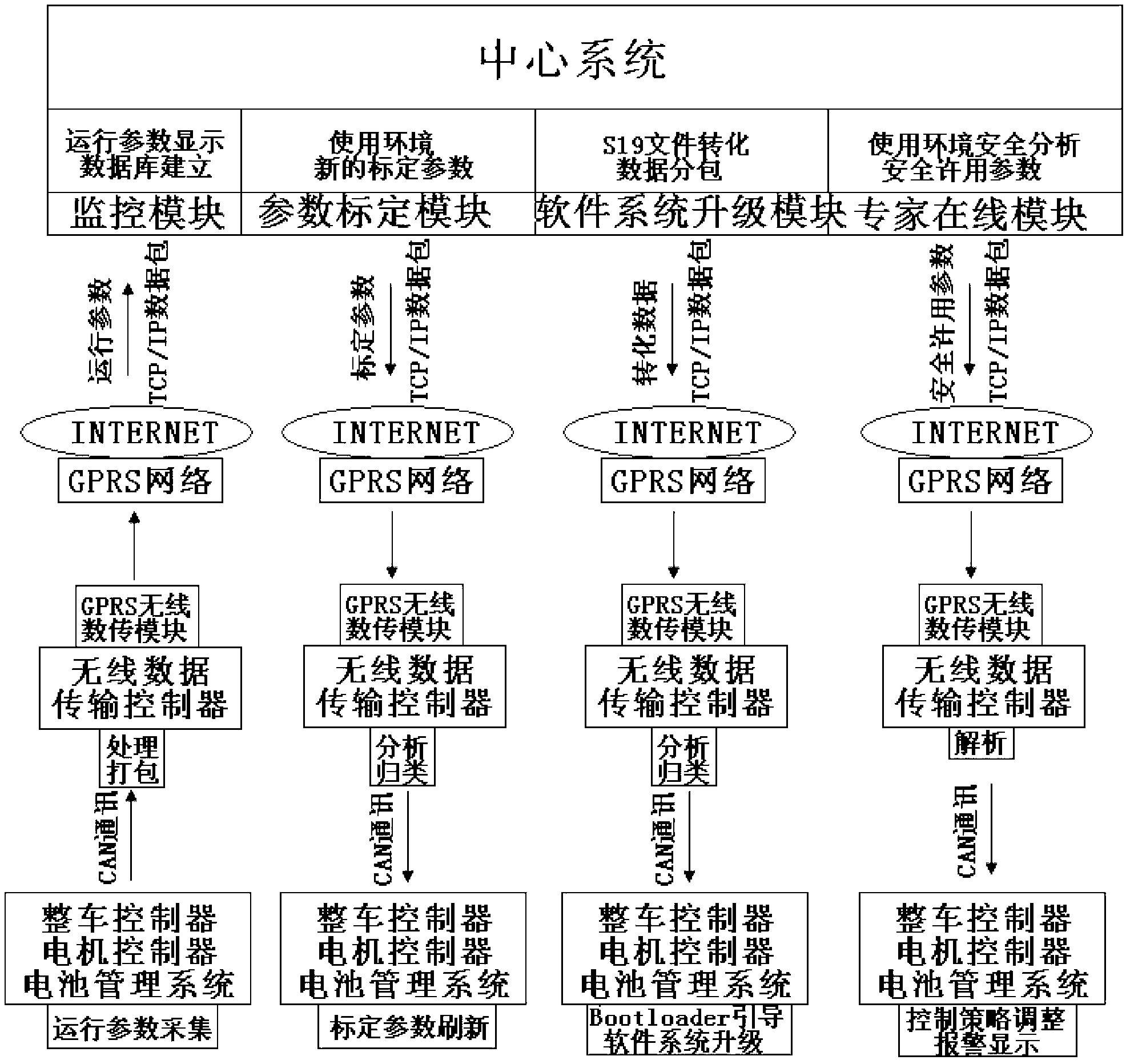

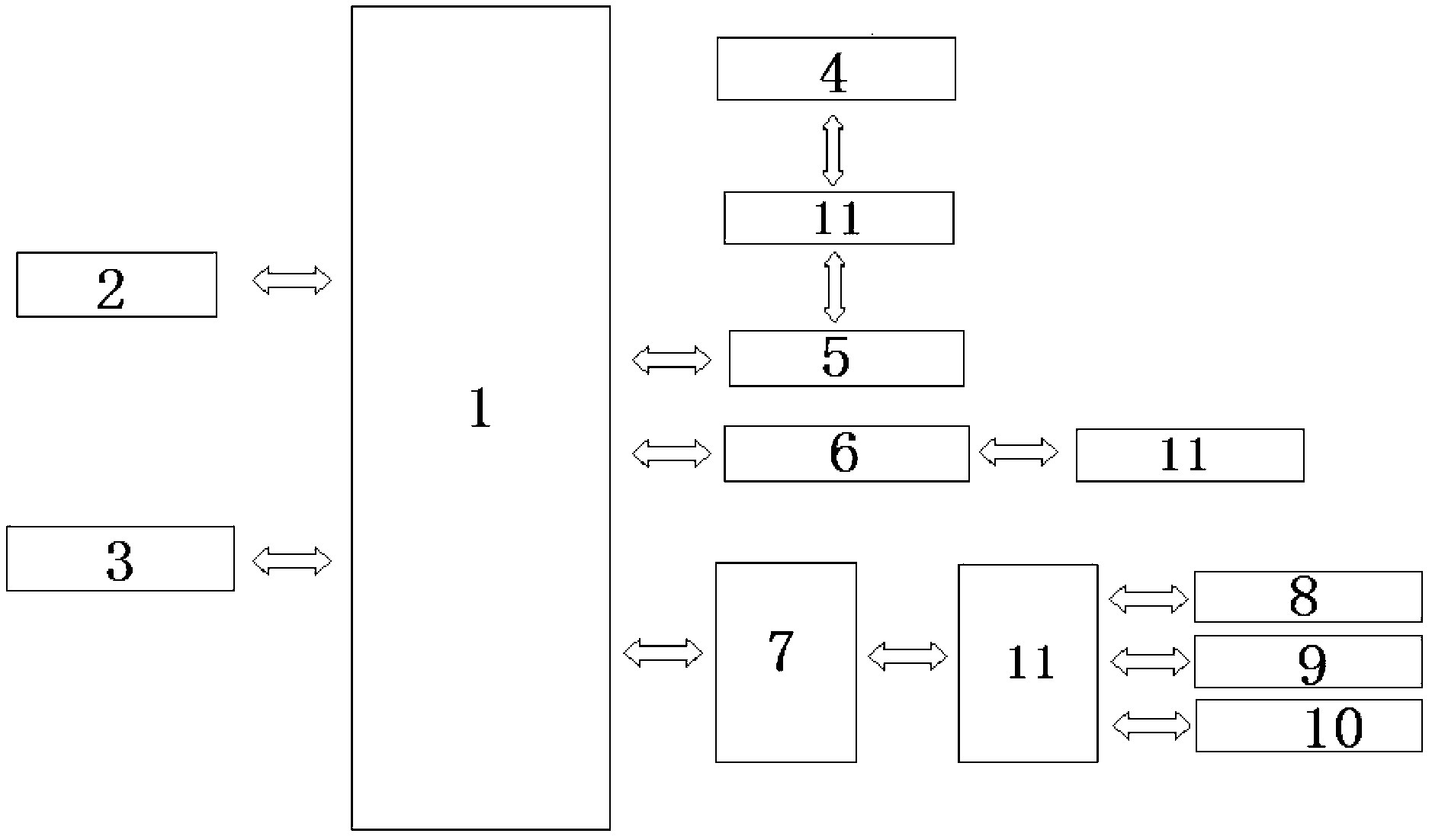

[0053] like figure 1 As shown in the flowchart of the present invention, in the monitoring state, the operating parameters and operating environment parameters of the vehicle controller 10, the motor controller 9 and the battery management system 8 are transmitted to the microcomputer of the wireless data transmission controller through the CAN bus interface 7. The processor 1, the wireless data transmission controller processes, analyzes and packs the data uploaded by the CAN bus interface 7, and transmits it to the wireless data transmission module 4 through the RS232 interface 5. The wireless data transmission module 4 converts the data into TCP / IP packets and sends them to GPRS On the network, the final data flows into the Internet. After the monitoring module obtains the TCP / IP packets of the data from the Internet, the data is restored through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com