Rotary drum evaporator

A rotary evaporator and drum-type technology, applied in the field of rotary evaporators, can solve the problems of high-power motor waste, inability to enlarge equipment, time-consuming and labor-consuming water baths, etc., to simplify operation, improve heat exchange efficiency, and save water and electricity resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

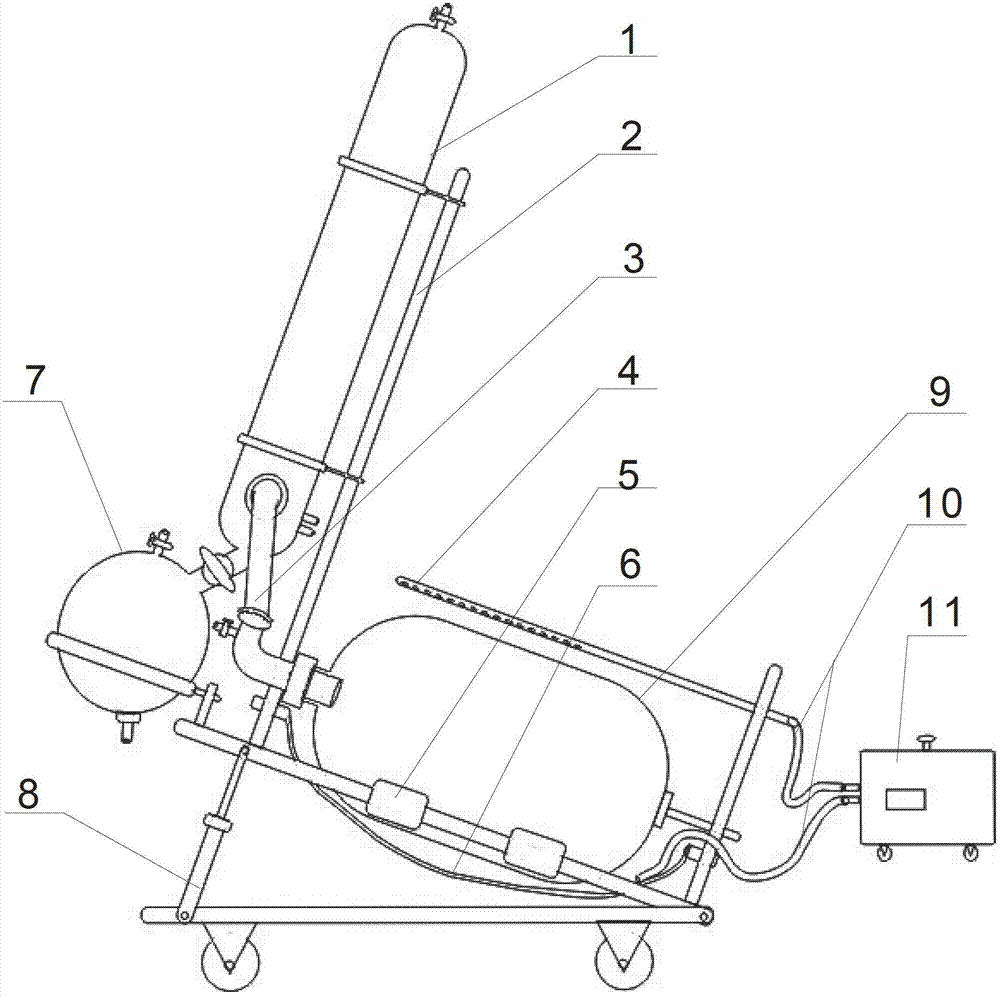

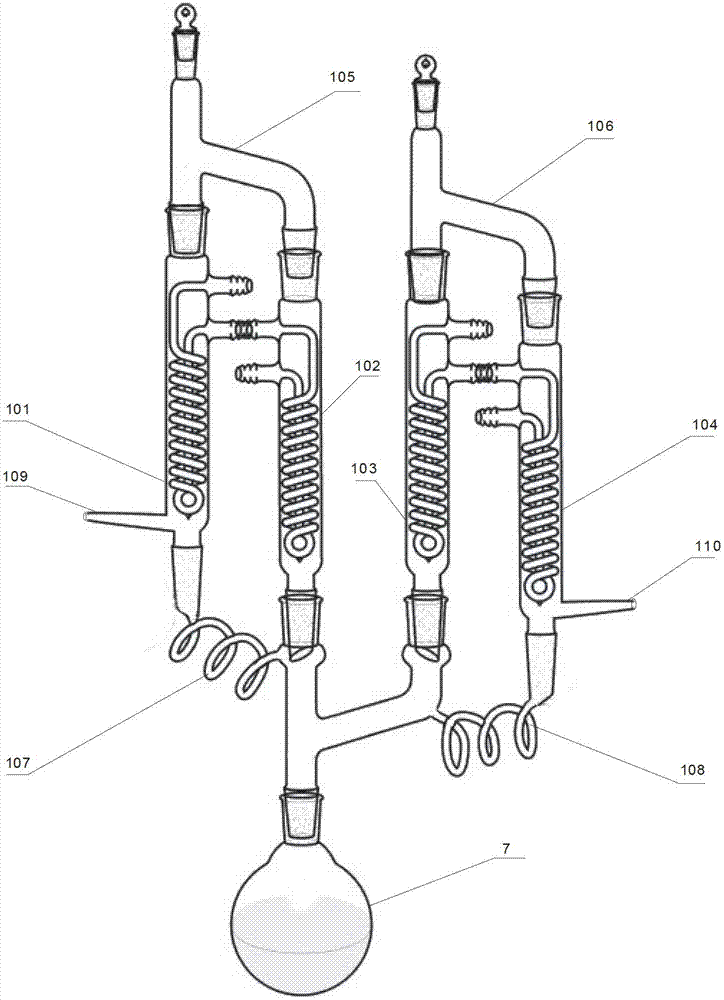

[0015] Implementation Option 1: If figure 1 As shown, a roller 5 is installed on the roller frame 8, and the roller 5 is driven by a speed-regulating motor, and the organic solution is placed in a rotating bottle 9, which is supported by the roller frame 8 and driven to rotate. After the circulating water is heated by the water bath 11, it flows out from the outlet end of the circulating water pipe 10 and sprays out from the nozzle of the nozzle 4, and the hot water flows down along the wall of the rotating bottle 9, and then is collected by the rotating bottle cover 6, and passes through the circulating water pipe The water inlet end of 10 flows back to the water bath, and through this cycle, the organic solution in the evaporating flask is continuously heated; when the organic solution is in a vacuum state, the rotation of evaporating flask 9 increases its evaporation area, thus vaporizing rapidly, resulting in The organic vapor enters the heat exchanger 1 along the sealing ...

Embodiment approach 2

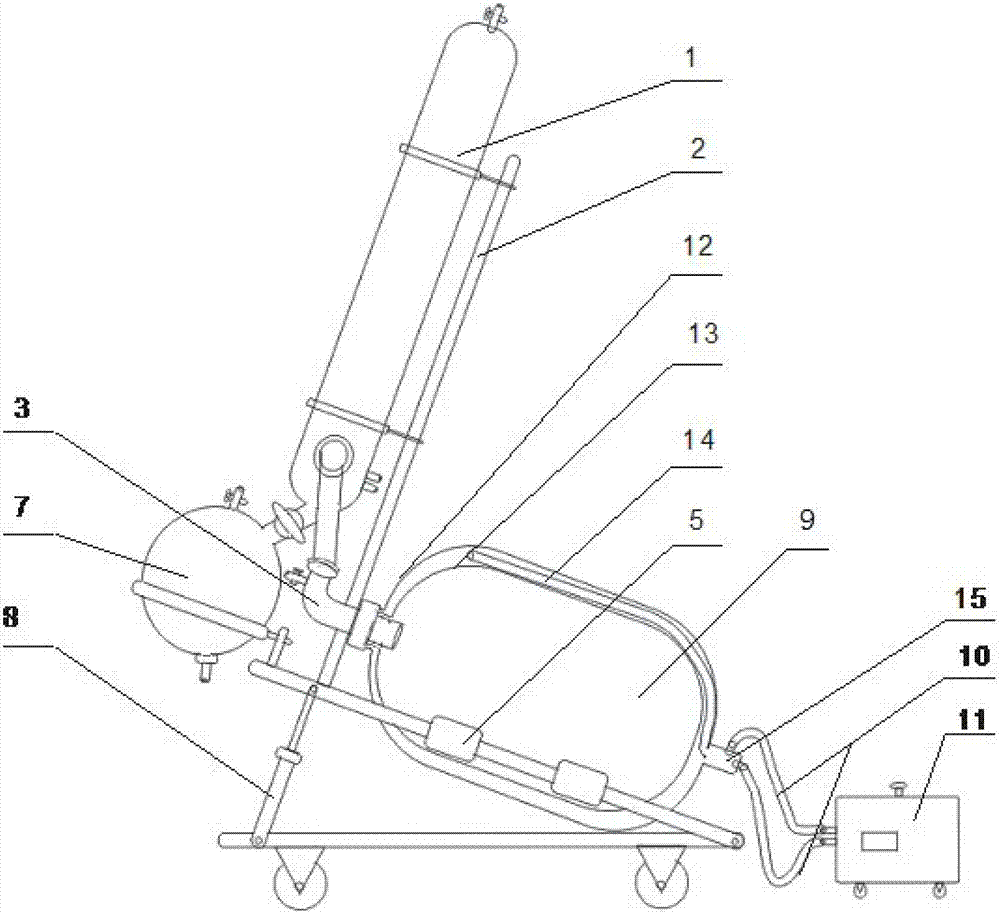

[0016] Implementation Option 2: If figure 2 As shown, a roller 5 is installed on the roller frame 8, and the roller is driven by a speed-regulating motor. The organic solution is placed in the evaporating bottle 9, which is supported by the roller frame 5 and driven to rotate. The evaporating bottle 9 has an outer bottle wall 12 and an inner wall. The double-layer structure of the layer bottle wall 13, and the lower end of the evaporating bottle 9 is provided with a double-channel rotary joint 15, and a section of pipeline 14 and a double-channel rotary joint 15 are arranged between the outer layer bottle wall 12 and the inner layer bottle wall 13. connected by a channel. After the circulating water is heated by the water bath 11, it flows out from the outlet end of the circulating water pipe 10 and enters the interlayer space formed by the inner and outer double walls of the evaporating bottle 9 along the double-channel rotary joint 15. When the water level reaches a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com