Hydraulic device with multiple oil cylinders in linkage

A technology of hydraulic device and oil cylinder, which is applied in the direction of fluid pressure actuating device, metal extrusion, metal extrusion control equipment, etc., can solve the problems of complex movements and large hydraulic pressure, achieve smooth switching, compact structure, and eliminate hydraulic pressure. impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

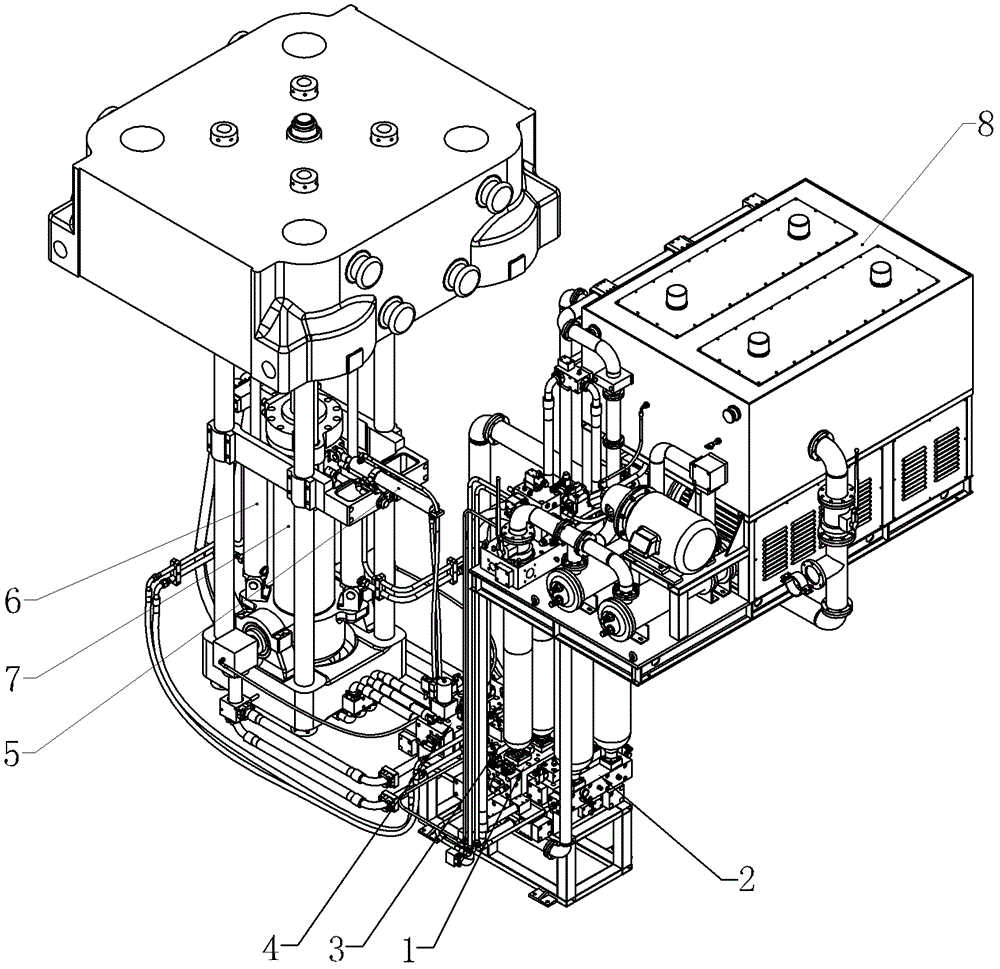

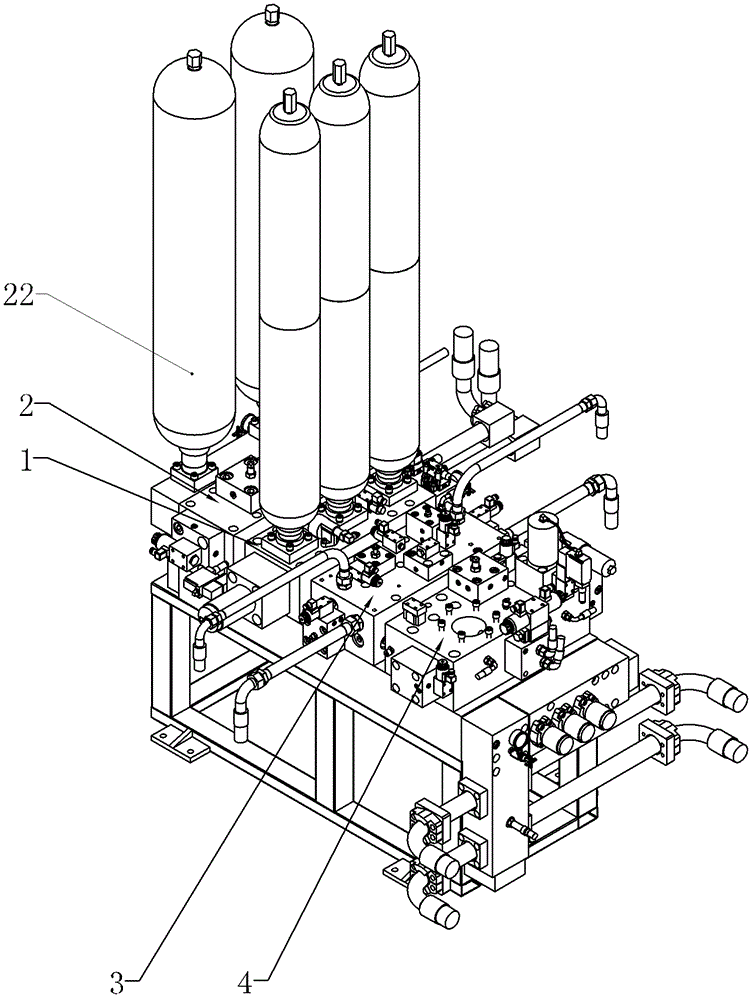

[0024] Such as Figure 1 to Figure 6 As shown, the multi-cylinder linkage hydraulic device of the present invention is mainly composed of a swing cylinder 5, a docking cylinder 6, an injection cylinder 7, a hydraulic pump station 8 and a hydraulic control device. The hydraulic control device is mainly composed of a high-pressure hydraulic control assembly 1 , medium pressure hydraulic control component 2, docking cylinder hydraulic control component 3 and return hydraulic control component 4.

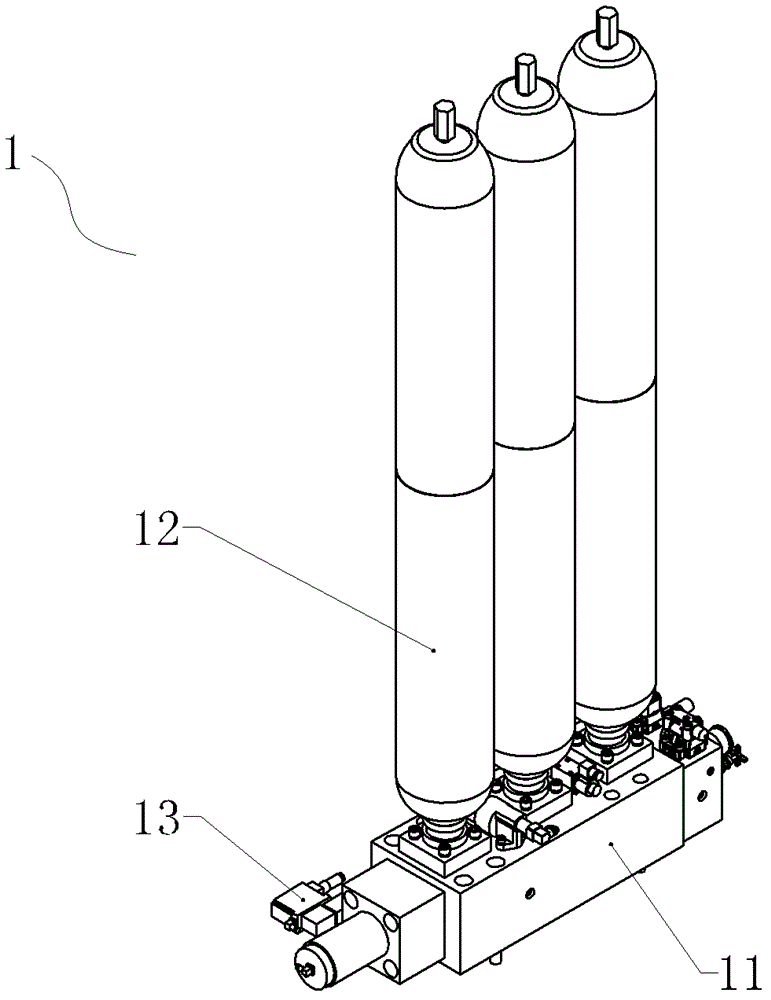

[0025] The high-pressure hydraulic control assembly 1 is mainly composed of a high-pressure oil circuit block 11 , three high-pressure accumulators 12 with a working pressure of 300 bar, and a high-pressure injection control solenoid valve 13 . The high-pressure oil circuit block 11 is provided with an oil inlet circuit and a high-pressure injection control oil circuit. Rodless cavity connection. Three high-pressure accumulators 12 are installed on the high-pressure oil circuit block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com