Double air channel wall for airplane

A dual air duct and air duct technology, which is applied to aircraft parts, air handling equipment, weight reduction, etc., can solve the problem that the single air duct scheme does not make full use of the cold source, so as to prevent condensation, reduce self-weight, and increase heat transfer effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Describe the use of the present invention on the aircraft in detail below in conjunction with accompanying drawing.

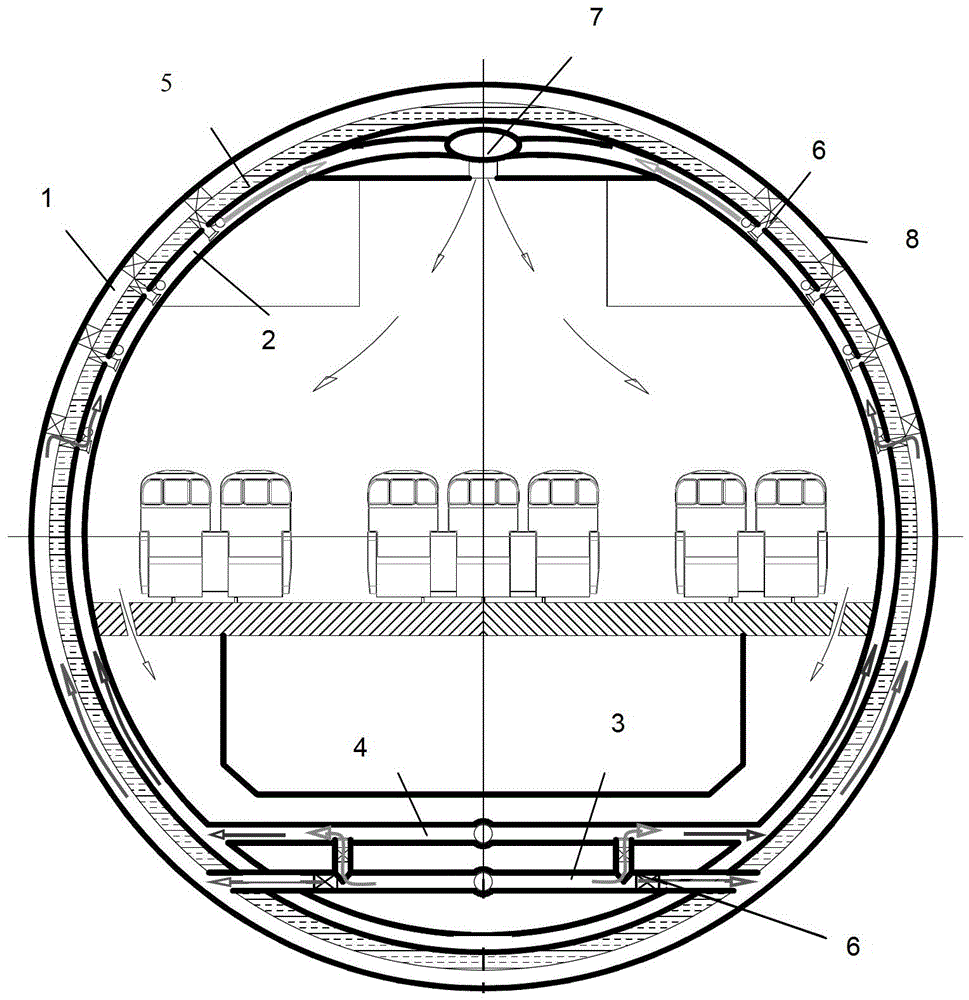

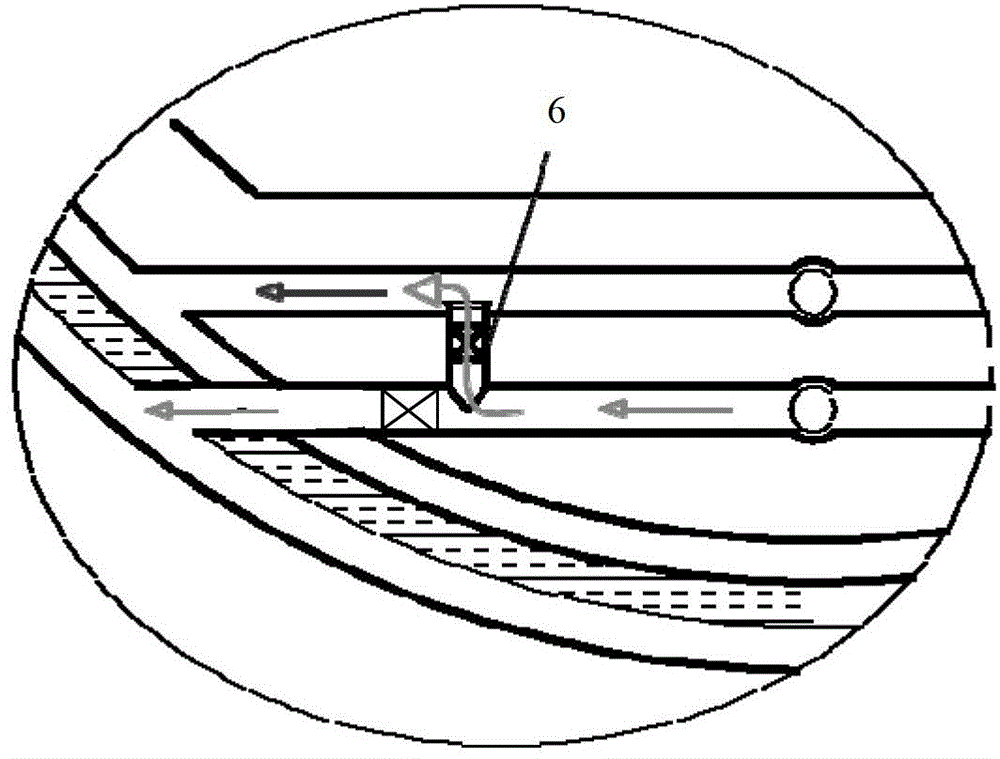

[0016] Such as figure 1 As shown, the air is supplied by double air ducts, and a sound insulation layer is provided between the two air ducts for sound insulation and reducing heat exchange between the two air ducts. The outer air duct is connected with the air conditioning component through the air supply duct, and the inner air duct is connected with the return air duct. Therefore, what flows in the outer air duct is fresh dry air, and what flows in the inner air duct is circulating air. The pipeline switcher arranged along the outer air duct is automatically controlled by the sensor. When the fresh dry air drops to close to the temperature of the cabin air supply, the pipeline switcher here is switched, and the air flow no longer goes upward along the outer air duct, but Pass through the sound insulation layer through the branch pipe and enter the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com