Intelligent multifunctional belt surface patch edge detection method

A technology of intelligent belt and edge detection, applied in image data processing, instruments, calculations, etc., can solve problems such as large errors, small probability, and no consideration of subdivision algorithms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

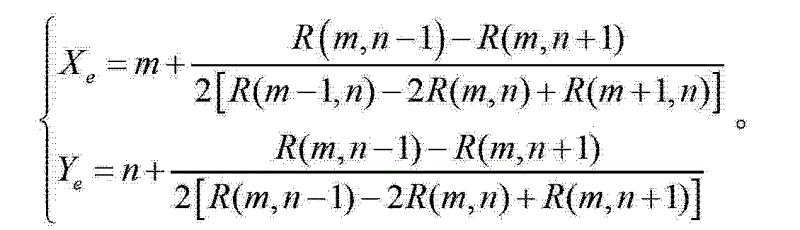

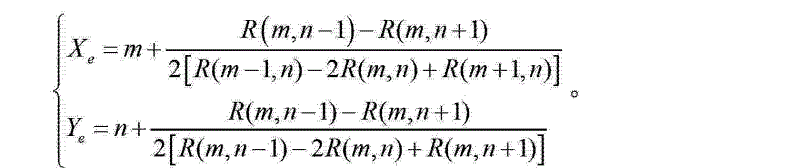

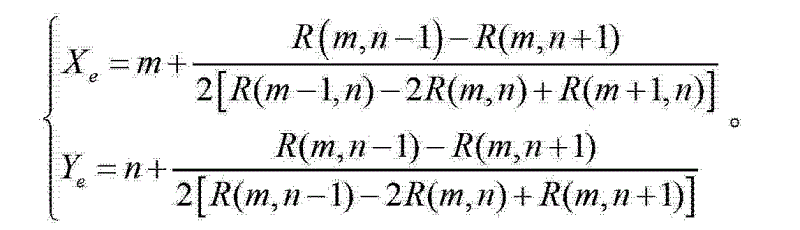

[0095] The multifunctional intelligent belt surface plaque edge detection method of the present invention adopts the machine vision online detection method, uses the linear array CCD to collect the image of the transmission belt running at high speed in real time, and conducts experimental research on the setting of the fault point threshold of the transmission belt. The self-made linear array CCD imaging device can be used to collect images of the high-speed transmission belt. First, the installation position of the light source determines the imaging effect, and it is necessary to conduct repeated tests on site to obtain the best light source installation position; The imaging device can collect images of the high-speed transmission belt. Since the measured object is a large-format device, it is necessary to select the best number of CCD cameras through repeated experiments to accurately capture images of the high-speed transmission belt; The image extraction and location alg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com