Luminescent material and light emitting device comprising such luminescent material

A technology of luminescent materials and light-emitting devices, which is applied in the direction of luminescent materials, semiconductor devices, gas discharge lamp parts, etc., can solve the problems of low chemical stability and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The detailed description of the embodiments given below will mainly focus on examples of light emitting materials. As for the light emitting device, system and method proposed in the present invention, useful descriptions have been given in the prior art and existing related papers or products can be referred to.

[0041] Example I

[0042] Example I refers to Ca 5 (PO 4 ) 3 F:Pr 3+ (l%)Na + (1%), which can be made in the following manner.

[0043] Starting material 1.009 g CaCO 3 , 4.0004 g CaHPO4 .2H 2 O, 0.32 g of nanoscale CaF 2 and 0.076 g of PrF 3 and 0.016 g of NaF were ground for 0.5 h. The mixture was then annealed at about 1100°C for 1 hour under nitrogen. Finally, the material was ground and sieved through a 36 μm sieve.

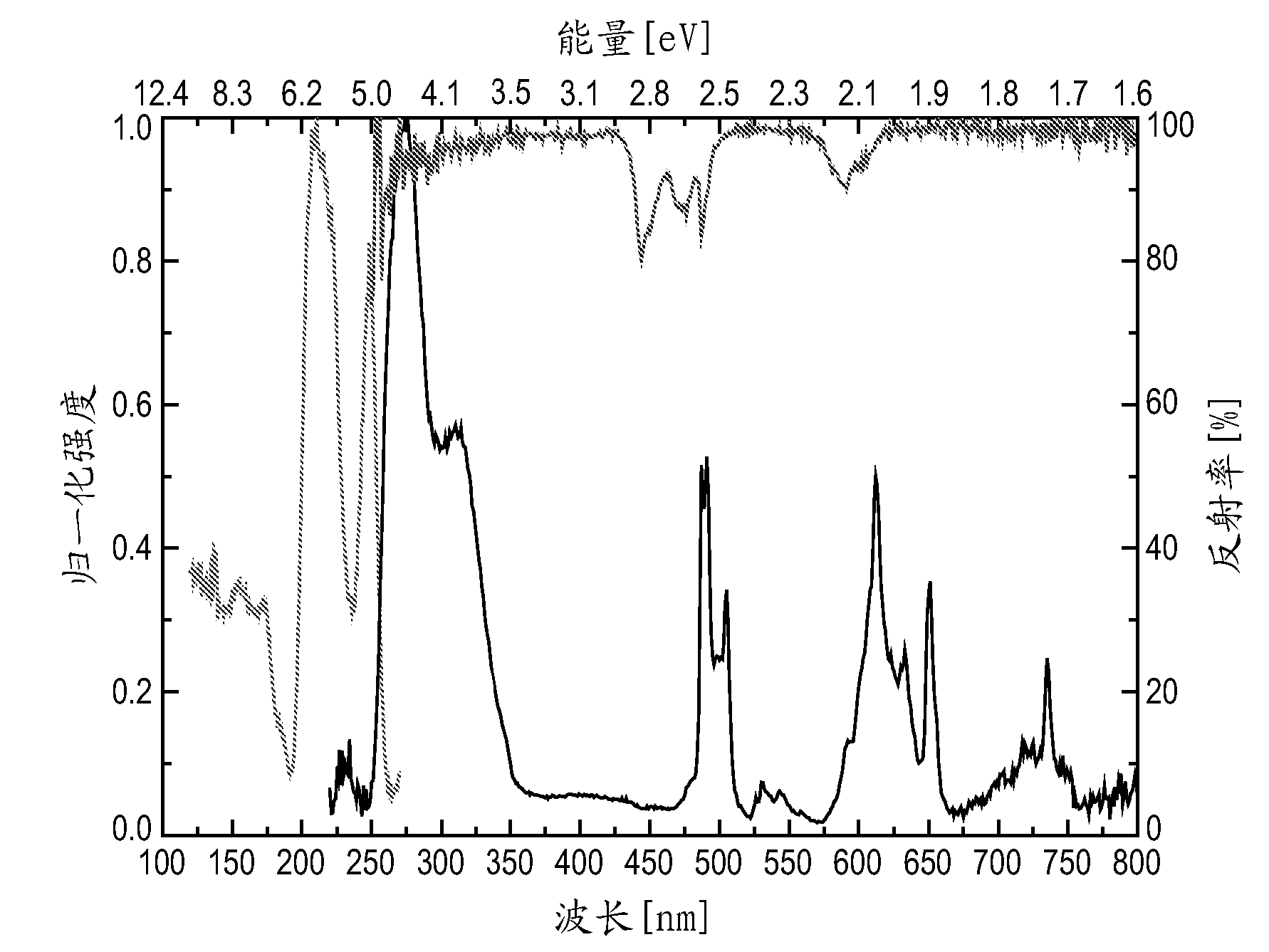

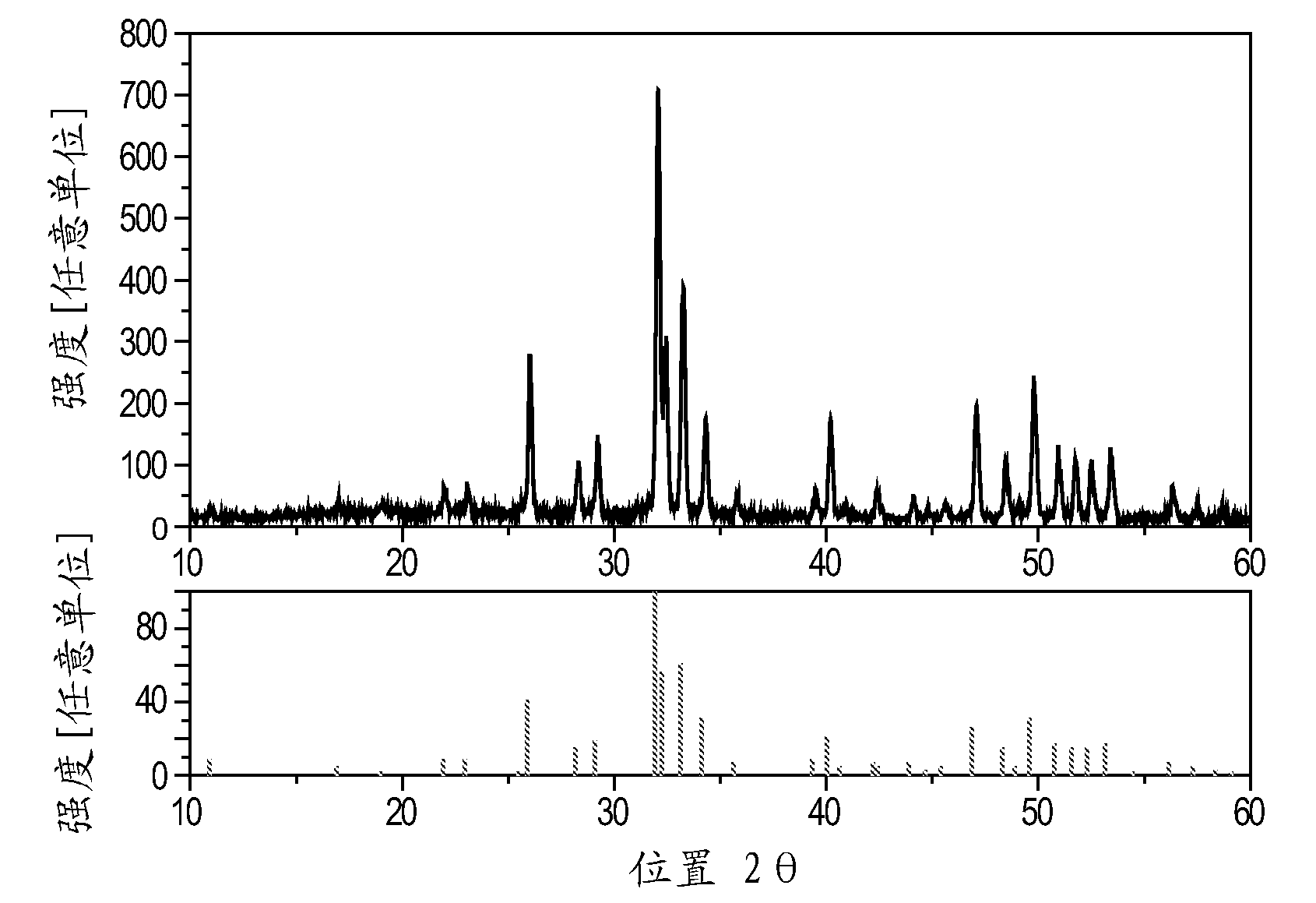

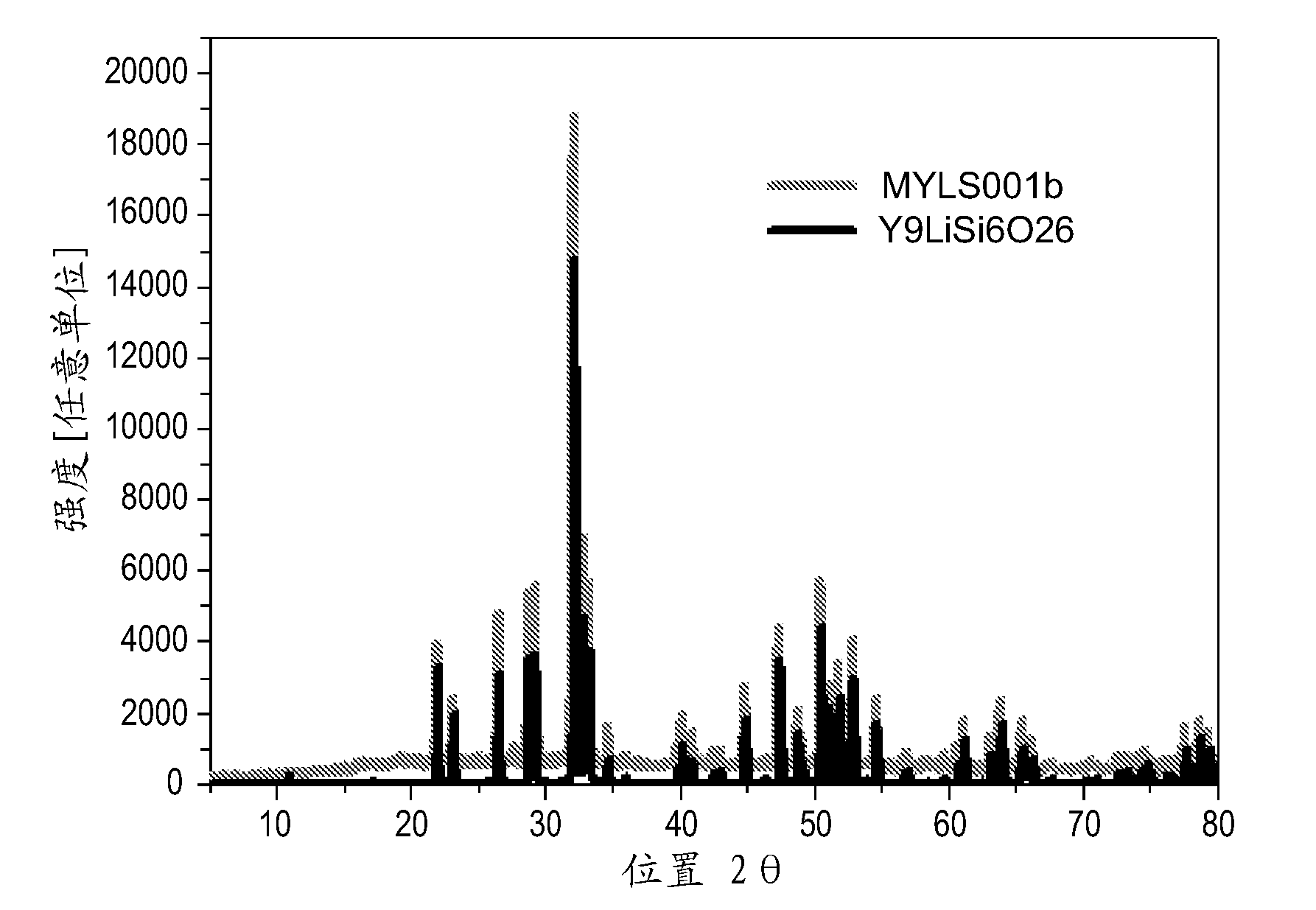

[0044] Figure 1 shows the XRD pattern of the material of Example I. Figure 2 shows the excitation spectrum (left spectrum), emission spectrum (right spectrum) and reflection spectrum (upper right spectrum) of the material of Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com