Instant curing rice with enriched nutrient and preparation method thereof

A nutritionally enhanced and cooked rice technology, applied in food preparation, food science, application, etc., can solve problems such as difficulty in controlling raw or gelatinized powder, unfavorable human health, poor taste, etc., to achieve easy rehydration and convenient consumption , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The preparation method of described ready-to-eat cooked rice comprises the following steps:

[0073] 1) Crush the rice to make rice noodles, and grind it with a grinder to make rice noodles with more than 40 mesh.

[0074] 2) Then add water to the rice noodles and add 0.30kg of water per kilogram of rice noodles; stir, the stirring speed is 180rad / min; Electric heating is used in the twin-screw machine, and the temperature is 100°C.

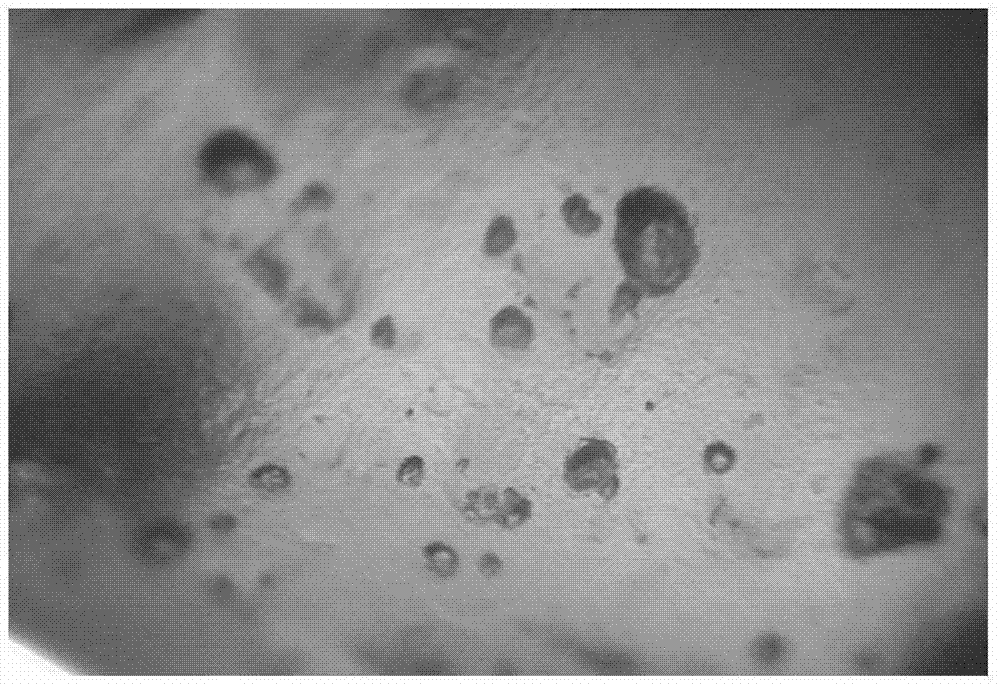

[0075] 3) The prepared granules are heated by microwave, and the temperature of microwave heating is 90°C; microwave heating is used to quickly dry and form a channel from the inside to the outside, so that the rice grains expand, and the expansion coefficient is 35%; and then sterilized by microwave. The temperature is 140°C; on the conveyor belt, the temperature is cooled by wind cooling, and the rice is packaged to become mature rice.

[0076] The diameter of the rice grains of the cooked rice is about 1.3 mm, and the length is about ...

Embodiment 2

[0079] The preparation method of described ready-to-eat cooked rice comprises the following steps:

[0080] 1) Crush the rice to make rice noodles, and grind it with a grinder to make rice noodles with more than 40 mesh.

[0081] 2) Then add water to the rice flour and add 0.08kg of water per kilogram of rice flour; stir, the stirring speed is 200rad / min; Electric heating is used in the twin-screw machine, and the temperature is 110°C.

[0082] 3) The prepared granules are heated by microwave, and the temperature of microwave heating is 80°C; microwave heating is used to quickly dry and form channels from the inside to the outside, so that the rice grains expand, and the expansion coefficient is 30%; and then sterilized by microwave. The temperature is 150°C; the temperature is cooled by wind on the conveyor belt, and the rice is packaged to become mature rice.

[0083] The rapid drying adopts microwave mode, and the temperature of microwave drying is 80-150°C.

[0084] The...

Embodiment 3

[0087] The preparation method of described ready-to-eat cooked rice comprises the following steps:

[0088] 1) Crush the rice to make rice noodles, and grind it with a grinder to make rice noodles with more than 40 mesh.

[0089] 2) Then add water to the rice noodles and add 0.45kg of water per kilogram of rice noodles; stir, the stirring speed is 150rad / min; Electric heating is used in the twin-screw machine, and the temperature is 90°C.

[0090] 3) The prepared granules are heated by microwave, and the temperature of microwave heating is 100°C; microwave heating is used to quickly dry and form a channel from the inside to the outside, so that the rice grains expand, and the expansion coefficient is 40%; and then sterilized by microwave. The temperature is 130°C; the temperature is cooled by wind on the conveyor belt, and the rice is packaged to become mature rice.

[0091] The rapid drying adopts microwave mode, and the temperature of microwave drying is 80-150°C.

[0092...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com