Sponge type gel membrane body material and manufacturing method thereof

A production method and technology of gel film, which can be used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve problems such as deep lines and easy crushing, achieve good foaming effect, enhance adsorption, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

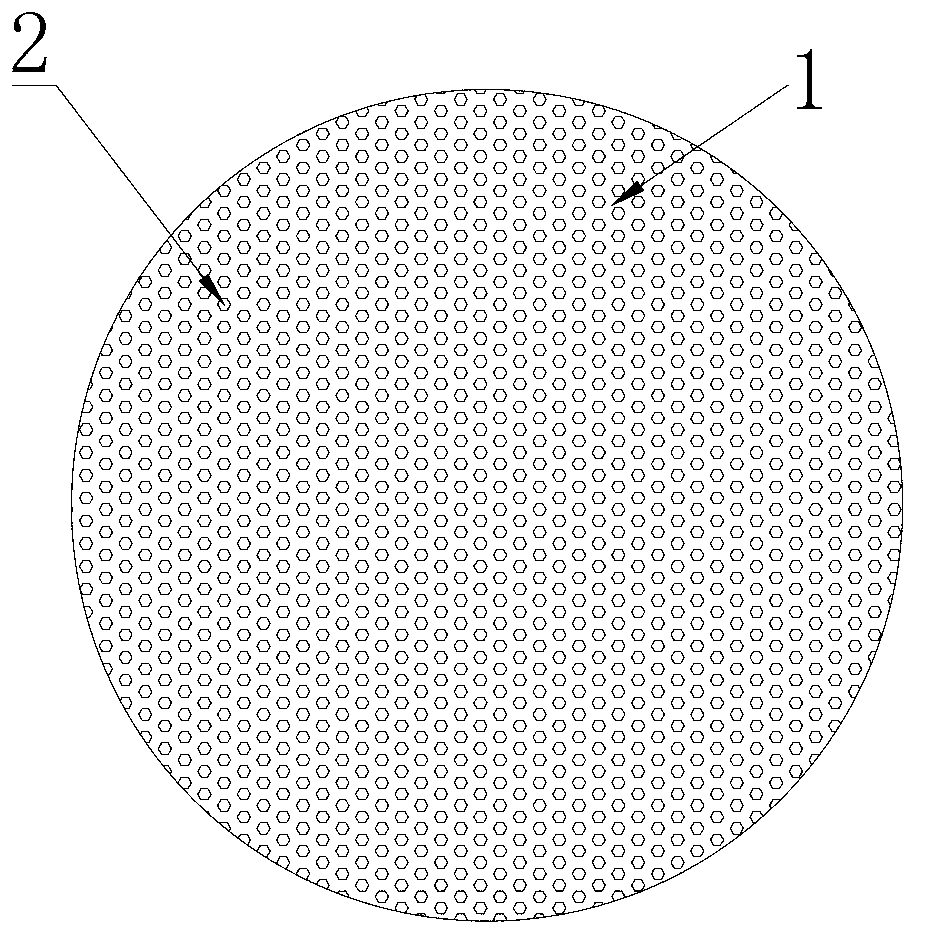

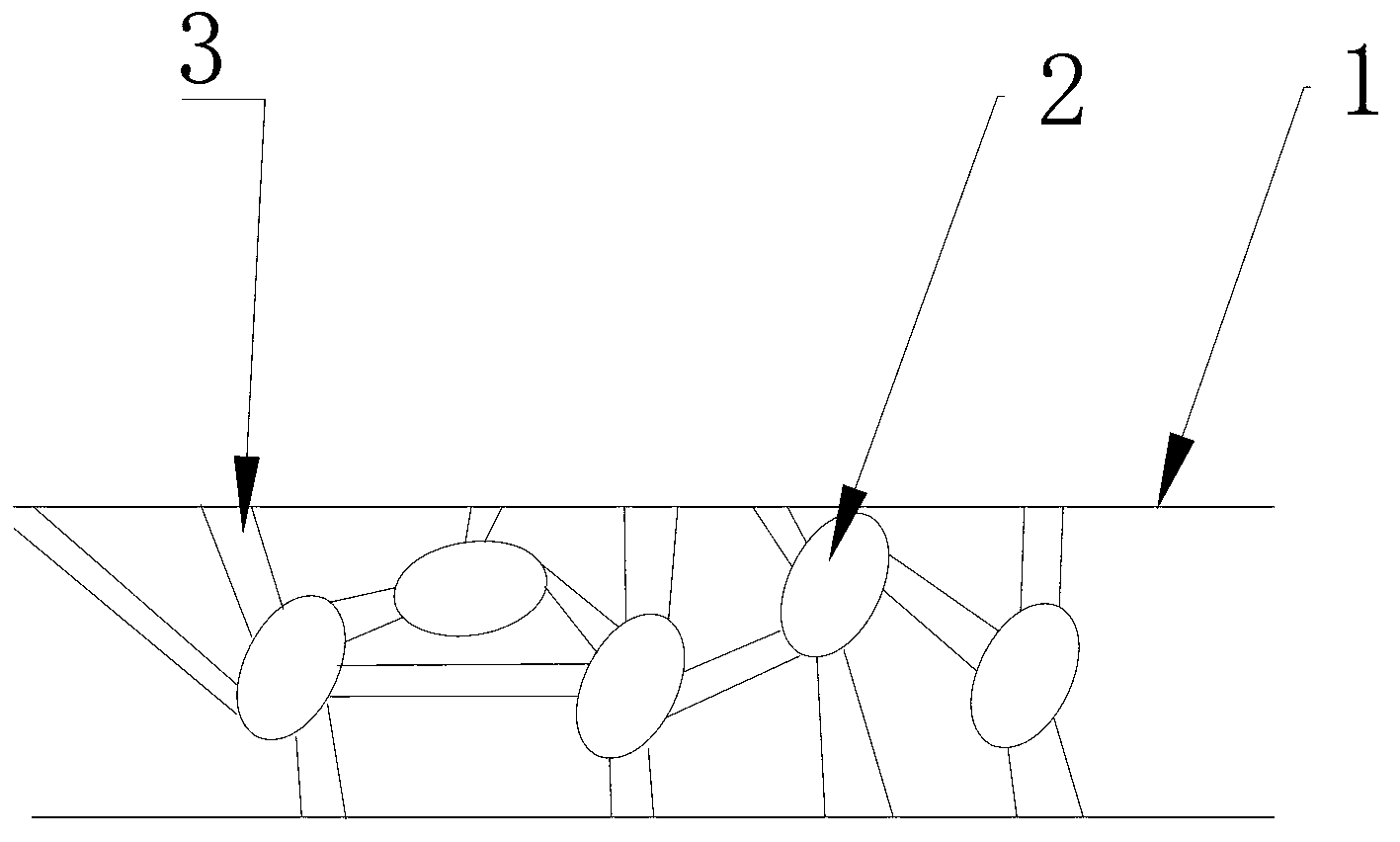

[0050] Such as figure 1 and figure 2 As shown, it is the spongy gel membrane material according to the present invention, which includes a hydrophilic gel membrane 1, and the inside of the hydrophilic gel membrane 1 is provided with several capsule cavities 2, each capsule The cavity 2 communicates with the surface of the hydrophilic gel membrane body 1 and / or the adjacent cavity 2 through at least one communication channel 3 .

[0051] The structure of the hydrophilic gel membrane body 1 can be a multilayer hydrophilic gel membrane composite structure; the material of the hydrophilic gel membrane body 1 can be collagen, carrageenan, konjac glucomannan, carob One of gum, acetylated glucomannan, xanthan gum, sodium alginate.

[0052] When the sponge-like gel film body material of the present invention is applied to a beauty sticking film, the beauty sticking film produced by the sponge-like gel film body material is placed in the functional substance and the essence, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com