Single-base granular-energetic colloidal explosive

A colloid and base particle technology, which is used in explosives, non-explosive/non-thermal agents, offensive equipment, etc., can solve the problems of inhomogeneous particles and colloids, unstable gel formation, etc., and achieve stable product quality and low manufacturing costs. , the effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Single-base particle-energy colloidal explosive is prepared from decommissioned single-base granular propellant, ammonium nitrate, sodium nitrate, Tianqing, urotropine, potassium tartrate, potassium pyroantimonate and water. In this example, the decommissioned single-base granular propellant uses a mixture of four granular propellants with different particle sizes, and the particle sizes are 16-18mm, 11-13mm, 5-8mm, and 2-4mm; the oxidant uses ammonium nitrate and sodium nitrate; Adhesive adopts Tianqing; gelling agent adopts compound composed of urotropine, antimony potassium tartrate and potassium pyroantimonate. Take by weight percentage:

[0027] Single base granular propellant 60

[0028] Ammonium nitrate 20

[0029] Sodium nitrate 9

[0030] Tian Qing 0.97

[0031] Herotropine 0.01

[0032] Potassium antimony tartrate 0.01

[0033] Potassium pyroantimonate 0.01 or 0.03

[0034] water 10

Embodiment 2

[0036] Single-base particle-energy colloidal explosive, made of decommissioned single-base granular propellant, ammonium nitrate, sodium nitrate, Tianqing, urotropine, antimony potassium tartrate, potassium pyroantimonate and water. In this example, the decommissioned single-base granular propellant uses a mixture of three granular propellants with different particle sizes, the particle sizes are 16-18mm, 5-8mm, and 2-4mm; the oxidant uses ammonium nitrate and sodium nitrate; the adhesive uses Tianqing ; The gelling agent is a compound composed of urotropine, antimony potassium tartrate and soluble antimony salt. Take by weight percentage:

[0037] Single base granular propellant 70

[0038] Ammonium nitrate 10

[0039] Sodium nitrate 9

[0040] Tian Qing 0.94

[0041] Herotropine 0.02

[0042] Potassium antimony tartrate 0.02

[0043] Soluble antimony salt 0.02 or 0.06

[0044] water 10

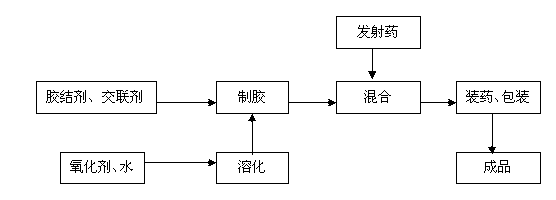

[0045] A preparation method of a single-base-energy colloidal explosive, compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com