Liquid-state lag tapping device of slack coal slag gasifier

A technology for slag gasification and slag discharger, which is used in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of slag and iron clogging, inconvenient disassembly, economic loss, etc., to reduce clogging frequency, promote slag discharge operation, prolong The effect of the run cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

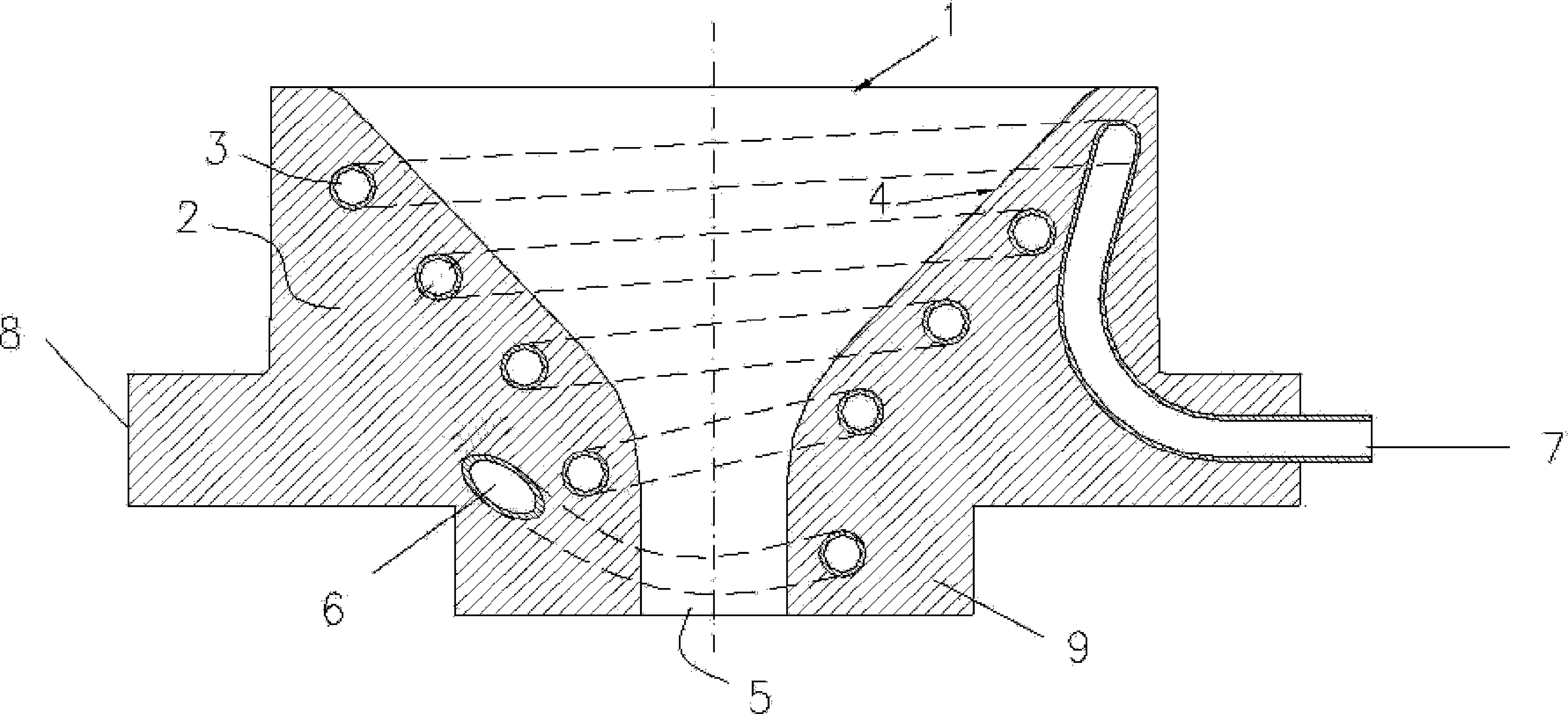

[0059] The overall width of the casting main body 2 is about 520mm, and the overall height is 240mm. The diameter of the slag outlet 5 is 65 mm, the height is 60 mm, and the horizontal angle between the merged part and the surface of the pouring tray is 45°. During installation, the protrusion 8 on the outer surface of the main body 2 of the liquid slag discharger 1 is used to connect with the support plate under the coal gasification pressure of the crushed coal slag gasifier, and is located at the bottom of the liquid slag discharger 1 The annular recess 9 at the lower part of the outer surface of the main body 2 is used for installing an annular burner, an air ring pipe and some pipes.

[0060] Using the liquid slag discharger of the crushed coal slag gasifier of the present invention can obtain the following beneficial technical effects:

[0061] 1. The main casting of the liquid slag discharger of the present invention adopts a metal or alloy with a thermal conductivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com