Thermal treatment method for super-thick steel plate

A heat treatment method and a technology of extra-thick steel plates, which are applied in the field of heat treatment, can solve problems such as difficulty, large internal stress, and coarse surface layer, and achieve the effects of good quenching effect, uniform structure, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

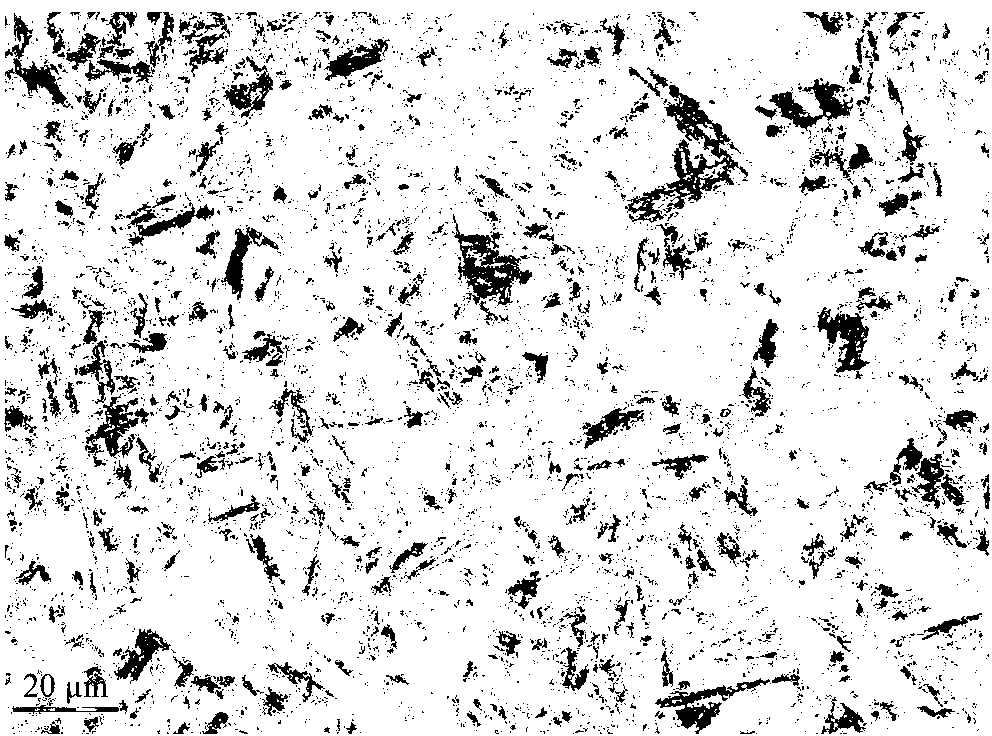

Image

Examples

Embodiment 1

[0027] The production specification is thickness × width × length = 100mm × 2200mm × 12000mm alloy steel plate.

[0028] The chemical composition of the extra-thick alloy steel plate of the above specifications is calculated by weight percentage (wt%) as follows: C0.38wt%, Si0.25wt%, Mn0.50wt%, P0.018wt%, S0.010wt%, Cr1.20wt%, Mo0.28wt%, Als0.025wt%, the rest is Fe and unavoidable impurities. Adopt the technological process of shot blasting treatment→heating in quenching furnace→cooling after furnace.

[0029] 1) Shot blasting treatment

[0030] The diameter of the steel shot is 2.0mm, and the rotational speed of the projectile is 100m / s.

[0031] 2) heating

[0032] The heating temperature is set at 920°C, the heating rate is 1.3°C / mm, the heat preservation time is 30min, and the time in the furnace is 160min±5min.

[0033] 3) Cooling after furnace

[0034] The running speed of the steel plate in the high-pressure section of the quenching machine is 3.0m / min, and the tim...

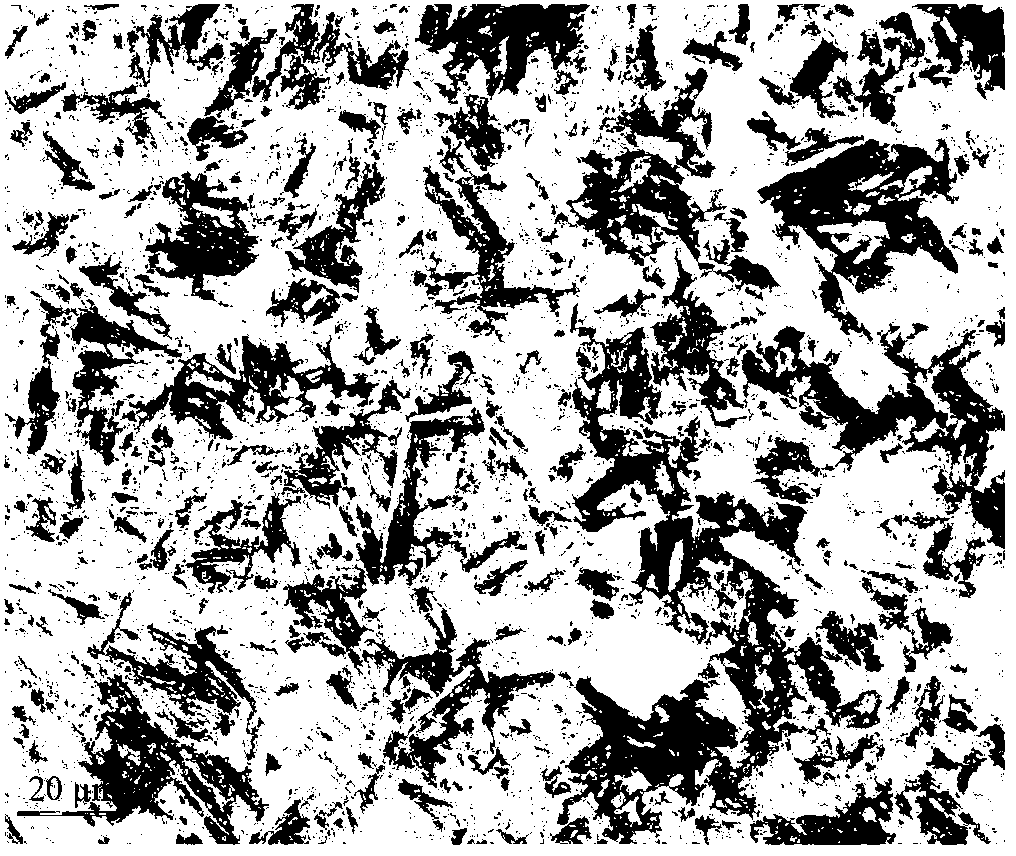

Embodiment 2

[0037] The production specification is thickness × width × length = 120mm × 2200mm × 9000mm alloy steel plate.

[0038]The chemical composition of the extra-thick alloy steel plate of the above specifications is calculated by weight percentage (wt%) as follows: C0.37wt%, Si0.23wt%, Mn0.55wt%, P0.015wt%, S0.008wt%, Cr1.30wt%, Mo0.25wt%, Als0.020wt%, the rest is Fe and unavoidable impurities. Adopt the technological process of shot blasting treatment→heating in quenching furnace→cooling after furnace.

[0039] 1) Shot blasting treatment

[0040] The diameter of the steel shot is 2.0mm, and the rotational speed of the projectile is 100m / s.

[0041] 2) heating

[0042] The heating temperature is set at 920°C, the heating rate is 1.3°C / mm, the heat preservation time is 30min, and the time in the furnace is 190min±5min.

[0043] 3) Cooling after furnace

[0044] The running speed of the steel plate in the high-pressure section of the quenching machine is 3.0m / min, and the time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com