Method for preparing three-dimensional thermoplastic composite material based on improved wrapped yarn structure

A composite material, wrapping yarn technology, applied in the direction of yarn, fabric, textile, etc., can solve the problem of poor resin dispersion, and achieve the effect of avoiding the reduction of mechanical properties, saving water resources, and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Raw material

[0040] The reinforcement of the three-dimensional orthogonal woven fabric composite material adopts ramie staple fiber yarn produced by Hunan Huasheng Dongting Lake Ramie Textile Co., Ltd., and the ramie staple fiber yarn with a fineness of 123.4tex is used as the warp and weft of the prefabricated part of the three-dimensional orthogonal woven fabric composite material The raw material of the yarn, the apparent characteristics of the radial direction of the yarn are as follows figure 2 As shown; the fineness is 38.7tex ramie staple fiber yarn as the raw material of Z yarn; the thermoplastic resin filament adopts the polylactic acid filament produced by Shanghai Yisheng Industrial Co., Ltd., and the fineness is 40.5tex.

[0041] 2. Equipment

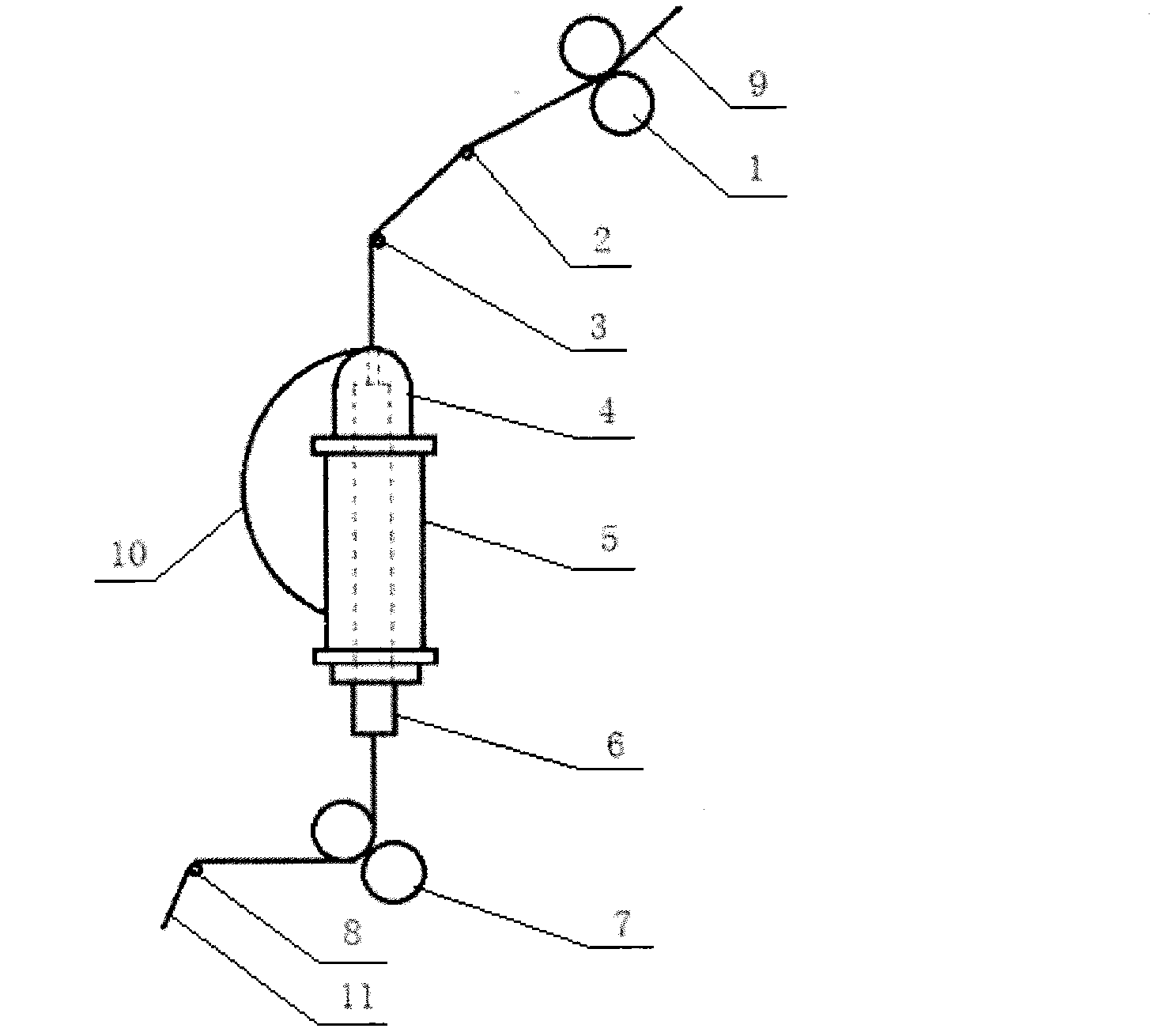

[0042]2.1 Wrapping device: fancy twisting machine (model is HN43-02-12, manufacturer is Suzhou Huafei Company) such as figure 1 As shown, it includes a hollow ingot 6, the hollow ingot 6 is provided with a wra...

Embodiment 2

[0057] 1. Raw material

[0058] The reinforcement of the three-dimensional orthogonal woven fabric composite material adopts ramie staple fiber yarn produced by Hunan Huasheng Dongting Lake Ramie Textile Co., Ltd., and the ramie staple fiber yarn with a fineness of 123.4tex is used as the warp and weft yarn of the three-dimensional orthogonal woven fabric composite material. Raw materials: ramie staple fiber yarn with a fineness of 38.7tex is used as the raw material of the Z yarn; the thermoplastic resin filament adopts PP filament produced by Shanghai Yisheng Industrial Co., Ltd., and the fineness is 54tex.

[0059] 2. Equipment

[0060] The wrapping device and preform weaving equipment are the same as in Embodiment 2.

[0061] 3. Specific steps

[0062] 3.1 Preparation of warp and weft yarns

[0063] Set the rotational speed of the hollow spindle 6 on the fancy twister, the speeds of the input roller 1 and the output roller 7 to 50Hz, 2.07Hz and 2.14Hz respectively, and ...

Embodiment 3

[0080] 1. Raw material

[0081] The reinforcement of the three-dimensional orthogonal woven fabric reinforced thermoplastic composite material adopts the hemp spun yarn produced by Hunan Huasheng Dongting Lake Ramie Textile Co., Ltd., and the hemp spun yarn with a fineness of 194.6tex is used as the prefabricated part of the three-dimensional orthogonal woven fabric composite material. Raw materials for warp and weft yarns; hemp spun yarns with a fineness of 52.7tex are used as raw materials for Z yarns; thermoplastic resin filaments are PLA filaments produced by Shanghai Yisheng Industrial Co., Ltd., with a fineness of 63.8tex.

[0082] 2. Equipment

[0083] The wrapping device and preform weaving equipment are the same as in Embodiment 1.

[0084] 3. Specific steps

[0085] 3.1 Preparation of warp and weft yarns

[0086] The rotating speed of the hollow spindle 6 on the fancy twisting machine, the speed of the input roller 1 and the output roller 7 are respectively set to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com