washing machine

A washing machine and outer cylinder technology, applied in the field of household appliances, can solve the problems of reducing the reliability of safety switches, poor parts versatility, and not meeting environmental protection requirements, etc., and achieve the effects of small wear, extended life, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

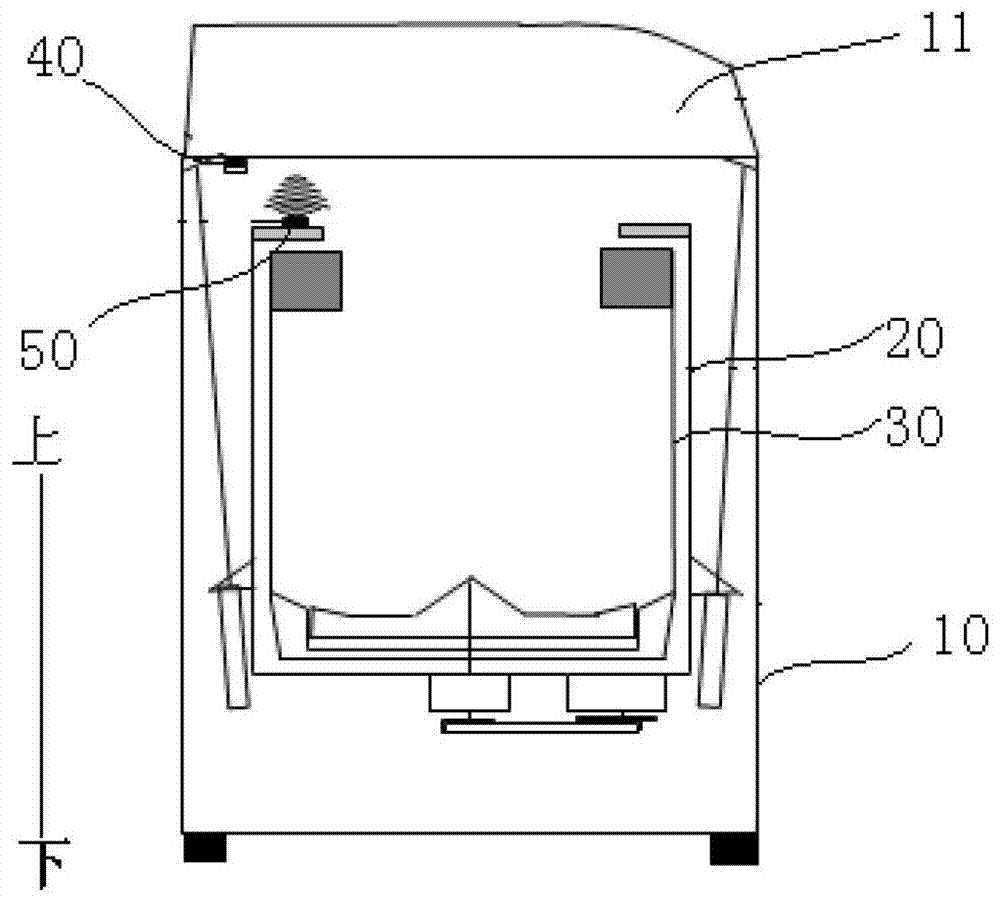

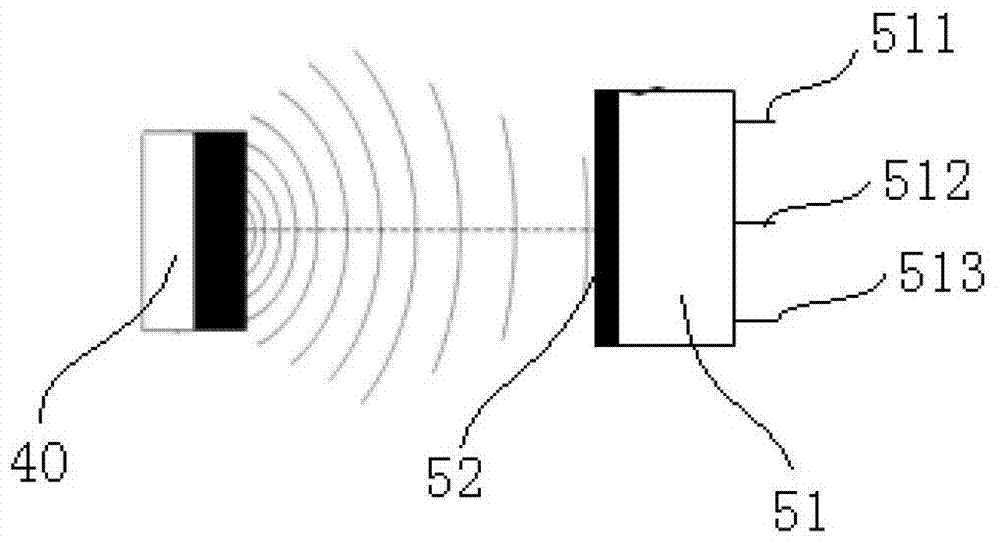

[0039] Such as figure 1As shown, the top of the outer cylinder 20 is open, the magnetoresistive sensor 50 is arranged on the upper part of the outer cylinder 20 and the magnetic field induction part 52 is arranged upward, and the magnetic part 40 is arranged under the workbench 11 and the magnetic surface of the magnetic part 40 is arranged downward.

[0040] Specifically, the reluctance sensor 50 is installed on the upper plane of the outer cylinder 20, the outer cylinder 20 is connected to the housing 10 through a suspension spring, and the rotation of the inner cylinder 30 during the dehydration process will drive the outer cylinder 20 to shake. The magnetic surface of the magnetic element 40 faces the magnetic field sensing portion 52 , and the magnetic element 40 is located outside the magnetoresistive sensor 50 in the radial direction of the outer cylinder 20 .

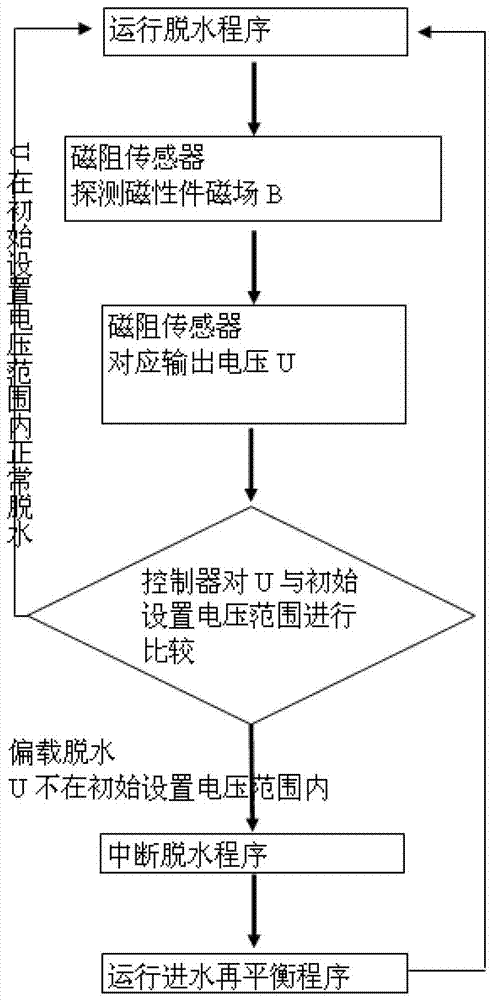

[0041] Combine below image 3 The dehydration process of the washing machine according to Embodiment 1 of th...

Embodiment 2

[0045] Such as Figure 4 As shown, the top of the outer cylinder 20 is open, the magnetic part 40a is arranged on the upper part of the outer cylinder 20 and the magnetic surface of the magnetic part 40a is arranged upward, and the magnetoresistive sensor 50a is arranged under the workbench 11 and the magnetic field induction part is arranged downward.

[0046] Specifically, the magnetic member 40a is installed on the upper surface of the outer cylinder 20, the outer cylinder 20 is connected to the housing 10 through a suspension spring, and the rotation of the inner cylinder 30 during the dehydration process will drive the outer cylinder 20 to shake. The magnetic surface of the magnetic element 40 a faces the magnetic field induction part, and the magnetoresistive sensor 50 a is located outside the magnetic element 40 a in the radial direction of the outer cylinder 20 .

[0047] The dehydration process of the washing machine according to Embodiment 2 of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com