Air door bridge and top camshaft engine

A valve bridge and valve technology, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems such as aggravating the unbalanced force of the valve, and achieve the effect of small width, avoiding insufficient strength, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

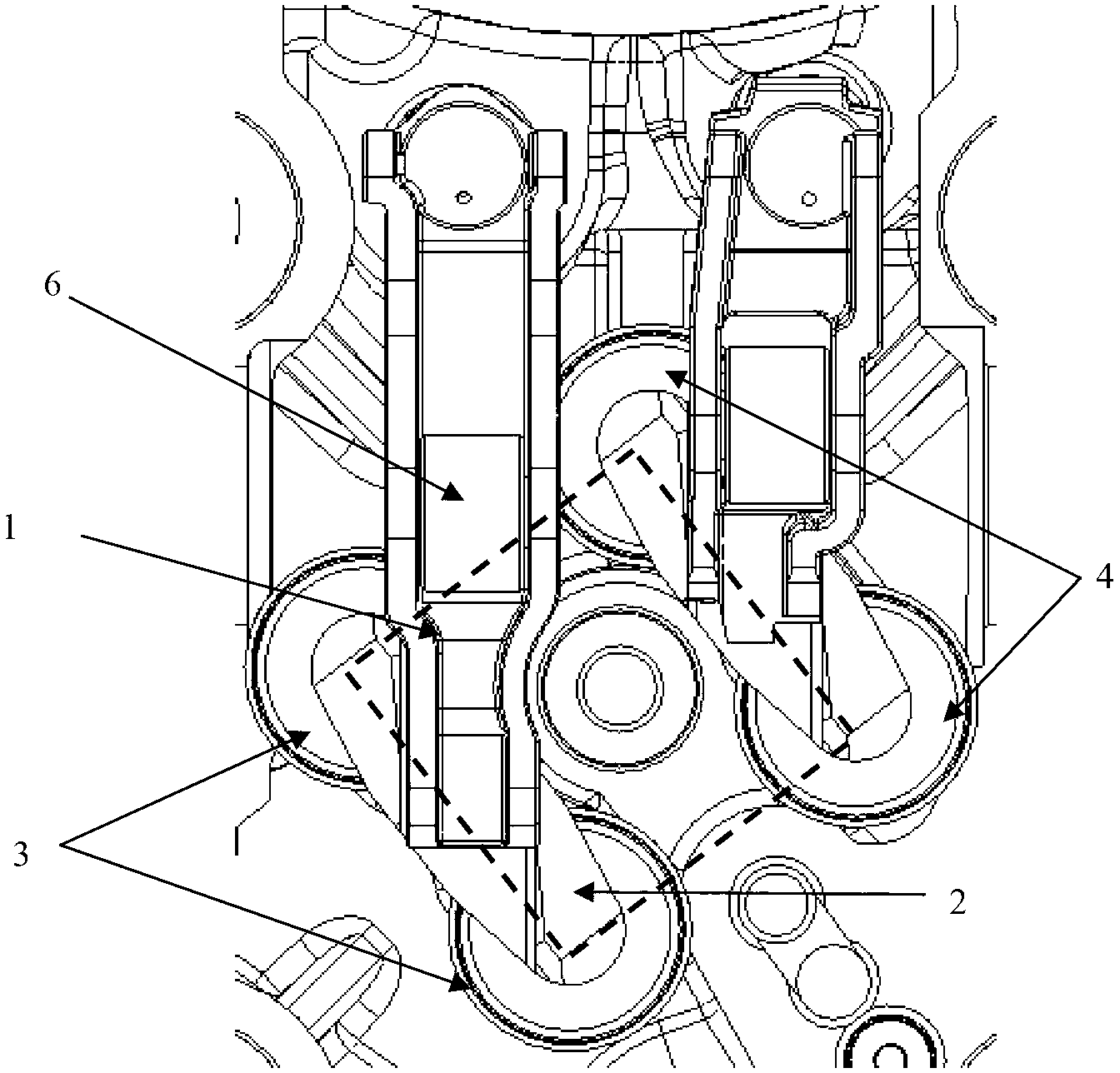

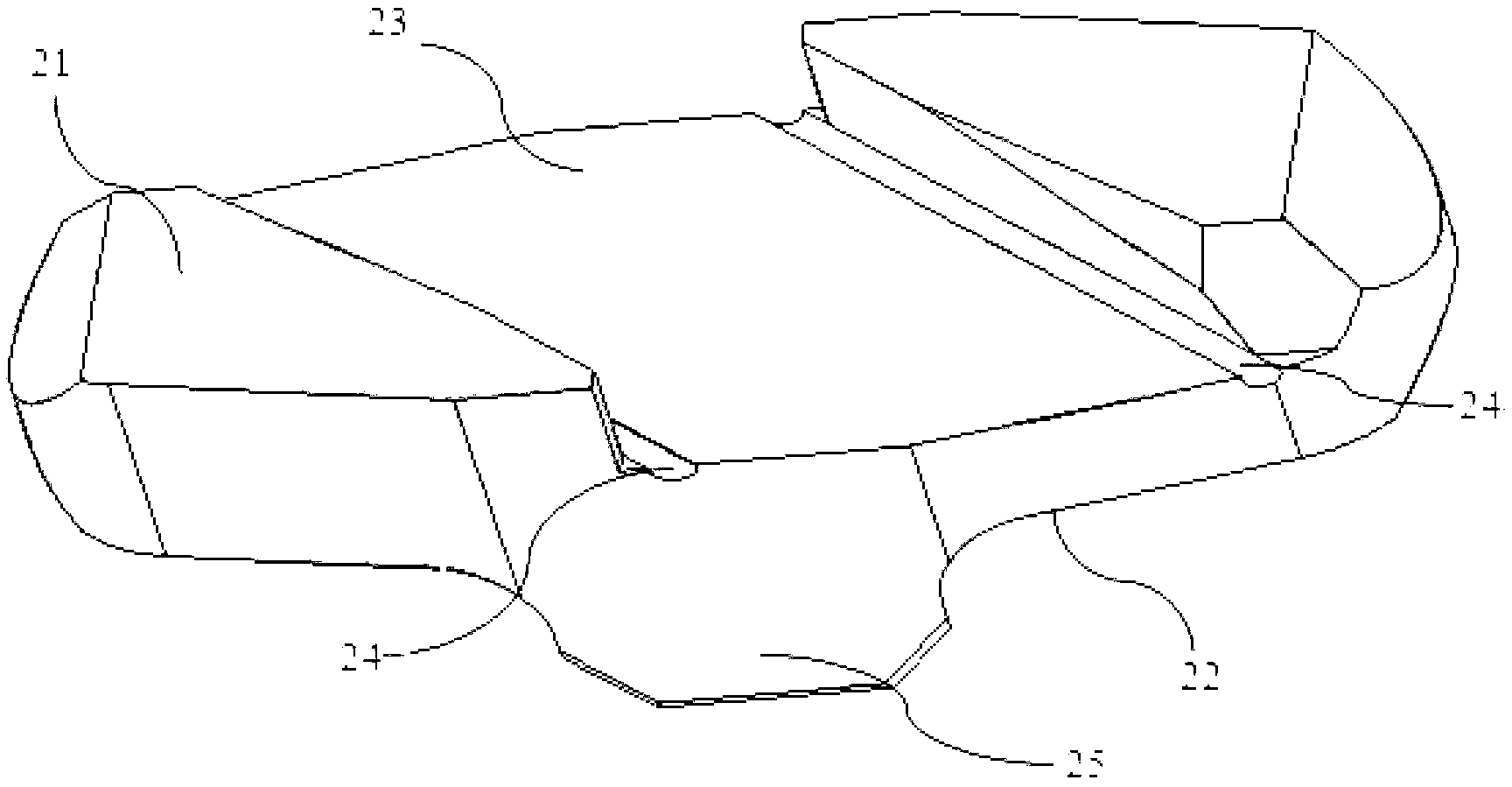

[0026] combine figure 1 and Figure 6 , the camshaft (not shown) of the overhead camshaft engine is located on the top surface of the cylinder head, and the cam of the camshaft is pressed on the rocker arm roller 6, so that the camshaft drives the valve rocker arm 1 to swing by rotation, and the valve rocker arm 1 Press down the valve bridge 2, the valve bridge 2 then presses down the intake valve 3 or the exhaust valve 4, and the intake valve 3 or the exhaust valve 4 is reset by the valve spring 5. In engine design, an important starting point is to realize the miniaturization and compact layout of the engine as much as possible, so the connection between the two intake valves 3 and the two exhaust valves 4 of the overhead camshaft engine forms a rhombus Arrangement (such as figure 1 shown by the dotted line).

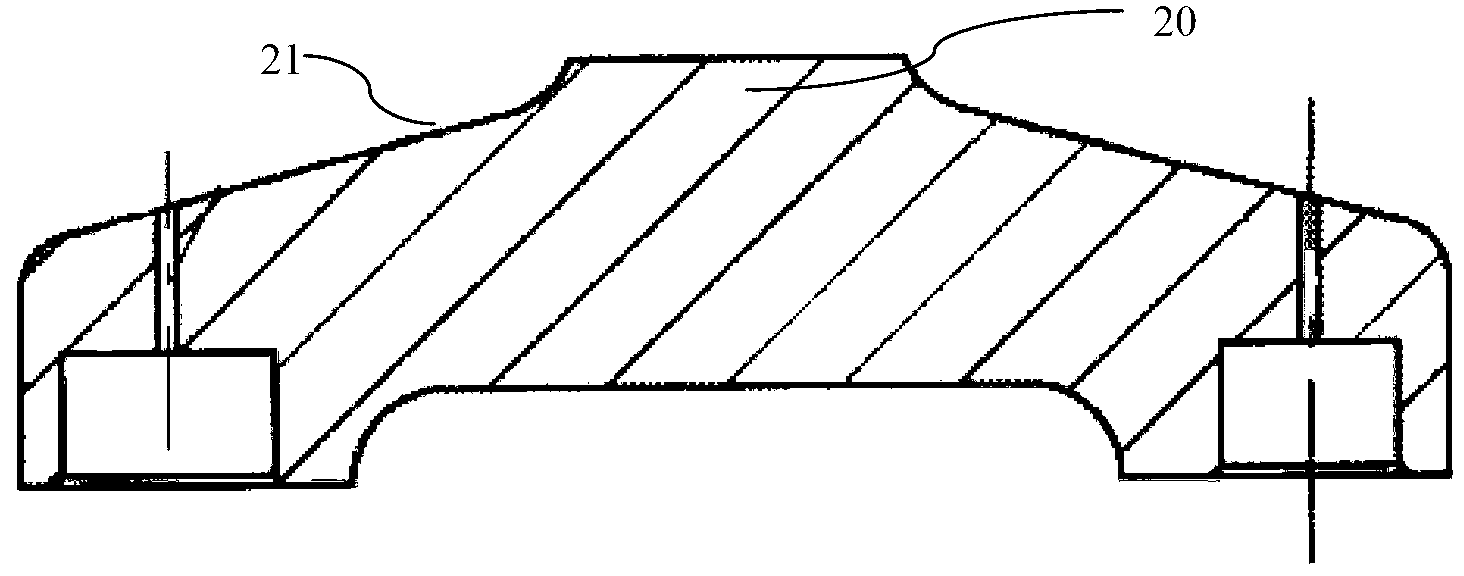

[0027] refer to figure 2 , in the prior art, the valve bridge 2 continues to extend upwards on the top surface 21 with a boss 20 , and the boss 20 is slidably ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com