Chemical heat regenerator

A regenerator and chemical technology, applied in the field of chemical regenerators, can solve problems such as energy waste, achieve the effects of reducing power consumption, increasing conversion rate, and improving cycle heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

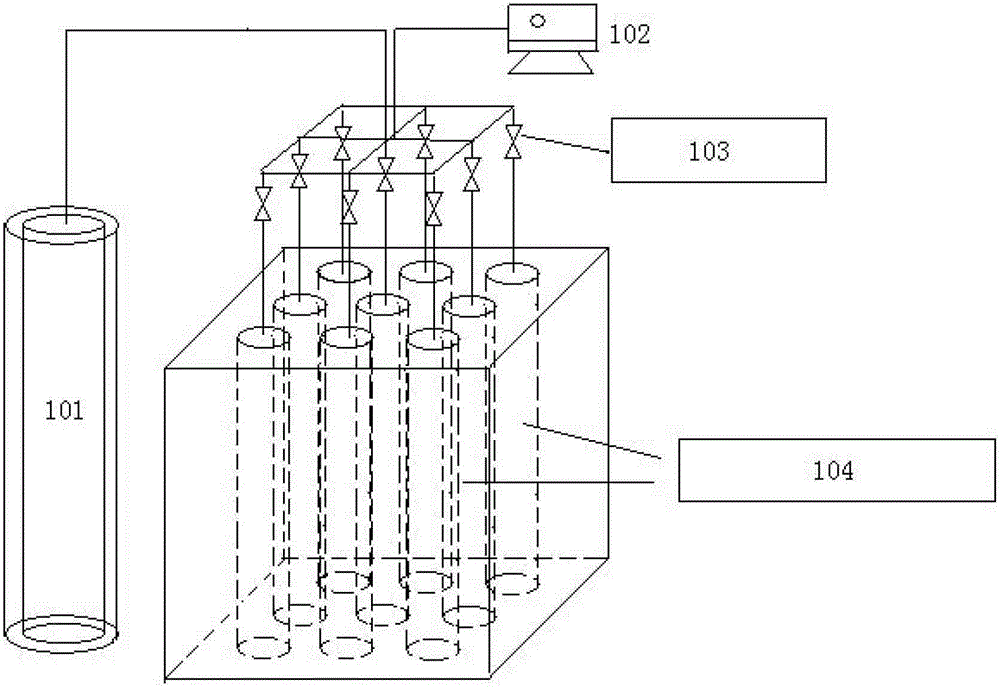

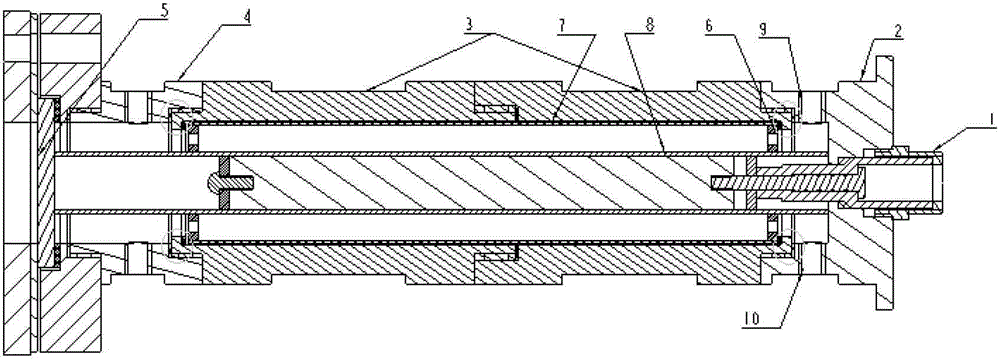

[0017] combine Figure 1~2 , the chemical regenerator device is composed of nine groups of low-temperature plasma catalytic reactors 104, and the reactors are arranged in a 3×3 manner. An electromagnetic valve 103 is set at the entrance of the reactor, and the closing of the electromagnetic valve 103 at the entrance of each reactor is controlled according to the total flow rate of 101 diesel steam and water vapor of the oil-gas blender under different working conditions, so that the reactants in the working state of the reactor stay The time is basically maintained within the optimal time range, ensuring high working efficiency of each reactor and reducing additional power consumption. The reactor mainly includes a power connection 1, a connecting section at the head of the outer casing 2, a connecting section at the middle of the outer casing 3, a connecting sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com