Mechanical transmission

A transmission and mechanical technology, which is applied in the direction of mechanical equipment, transmission devices, components with teeth, etc., can solve the problem of increasing the total volume and weight of the transmission mechanism, increasing the thickness of the synchronizer and corresponding gears, and the structure of the shift control part Complications and other issues, to achieve the effect of reducing fuel consumption, reducing bending moment, and improving driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

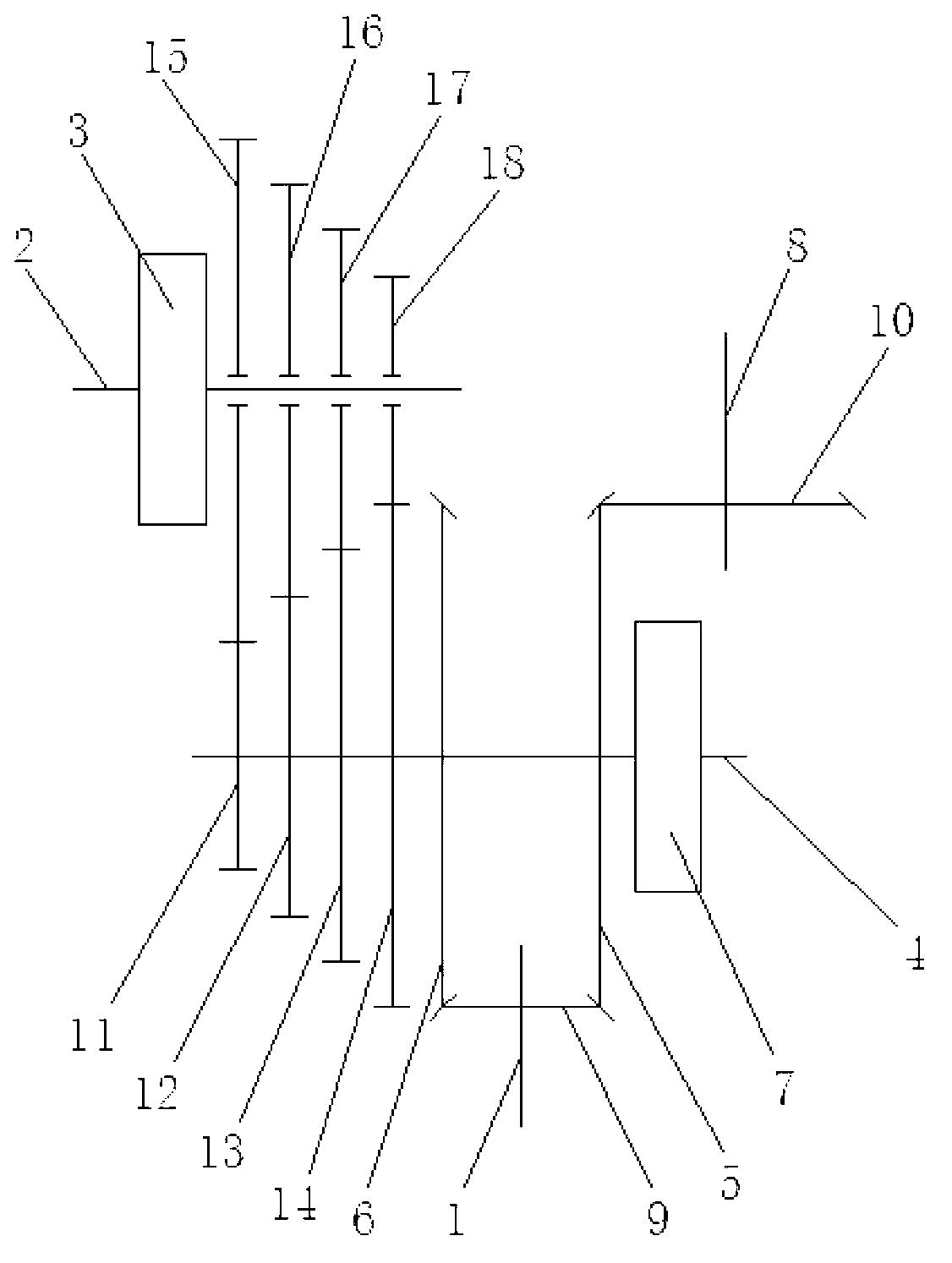

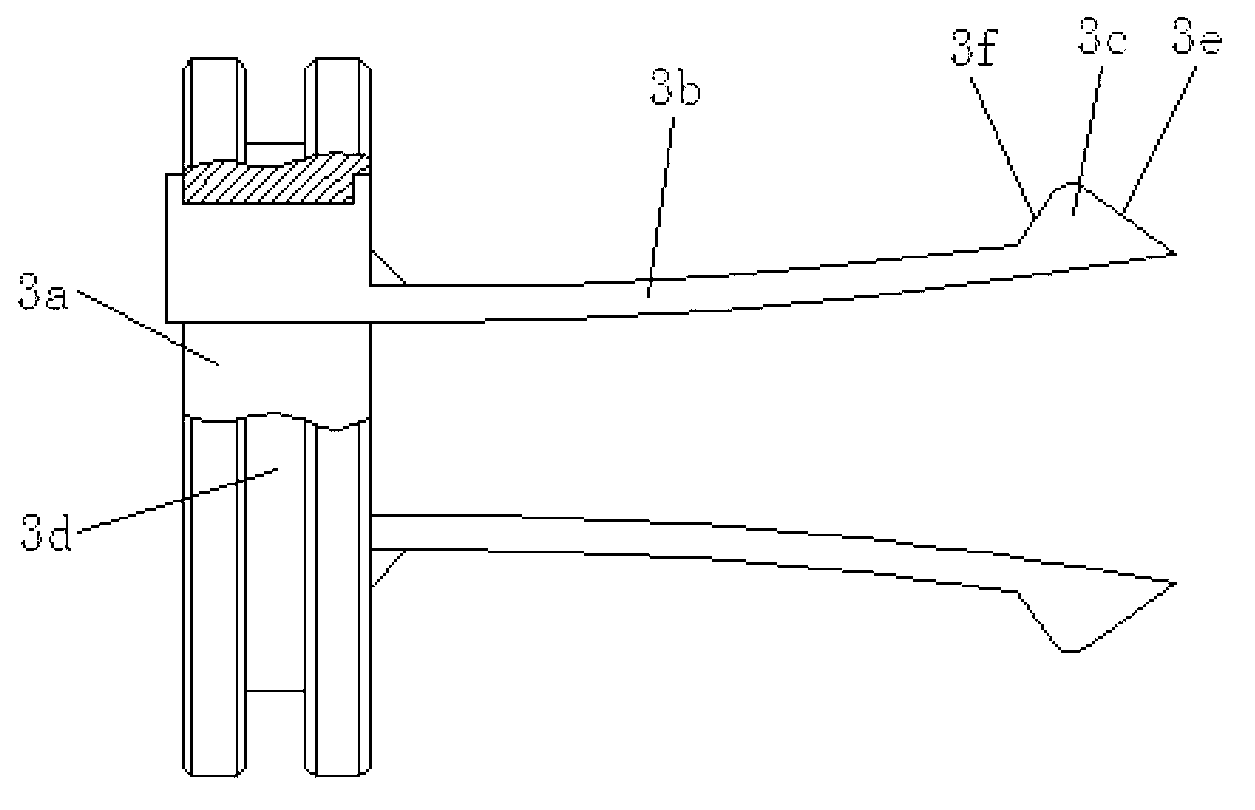

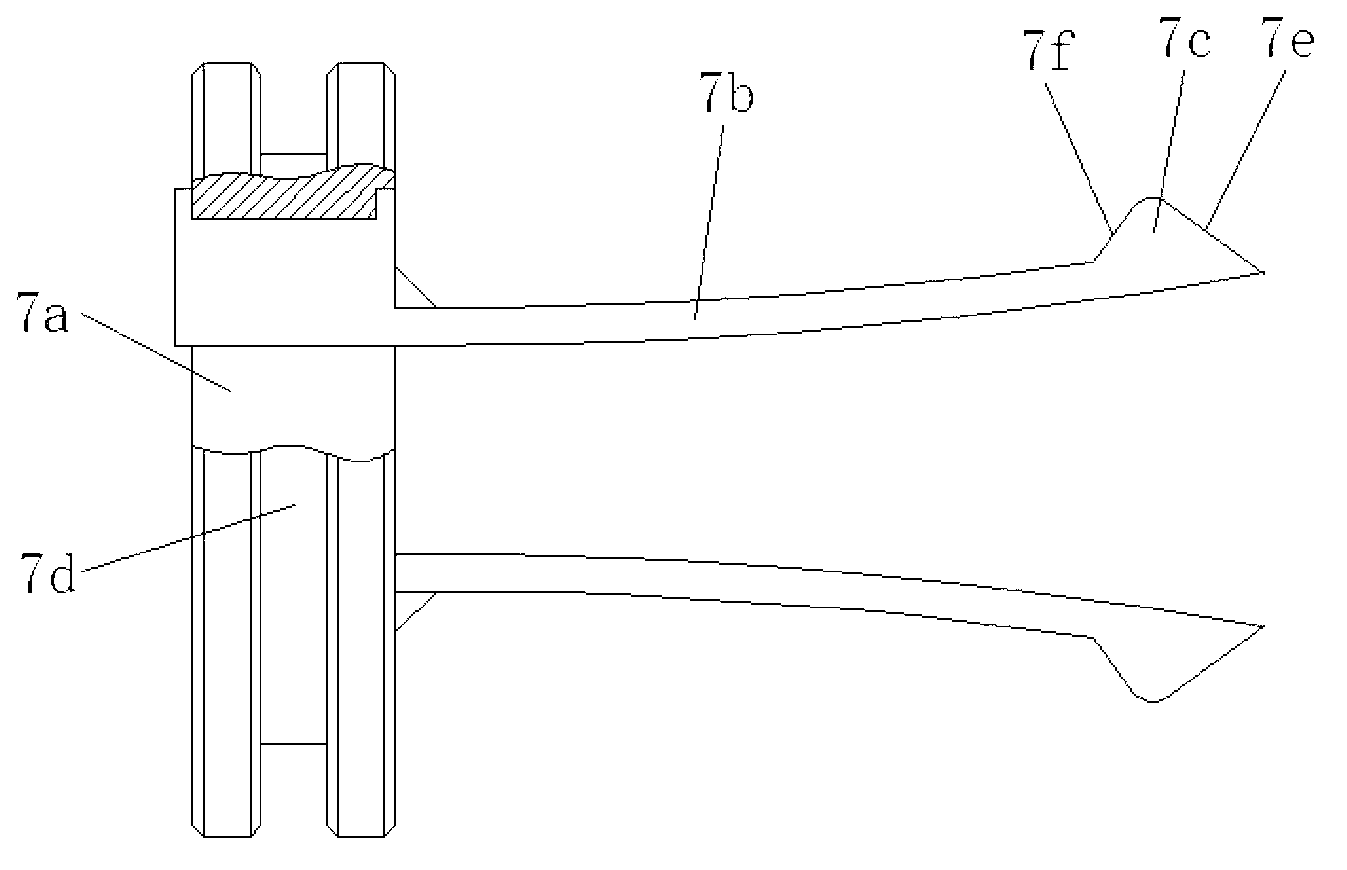

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the synchronous shifting part, image 3 It is a structural schematic diagram of the synchronous reversing member, as shown in the figure: the mechanical transmission of this embodiment includes a box body (not shown in the figure) and a speed change mechanism located in the box body, and the speed change mechanism includes a driving gear shaft 4, a driving gear group, driven gear shaft 2, driven gear set and synchronous shifting member 3, said driving gear set includes several driving gears set according to the gear position, said driven gear set includes one-to-one correspondence with the driving gear according to the gear position Several driven gears for meshing transmission, the synchronous shift member 3 includes at least a shift pawl 3b that can be axially driven;

[0023] The driving gear is arranged on the driving gear shaft 4 in tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com