Rotating servo valve capable of realizing continuously and steplessly adjustable flow rate

An adjustable and servo valve technology, applied in the field of rotary servo valves, can solve the problems of different valves, achieve the effects of reducing manufacturing difficulty, compensating radial unbalanced force, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

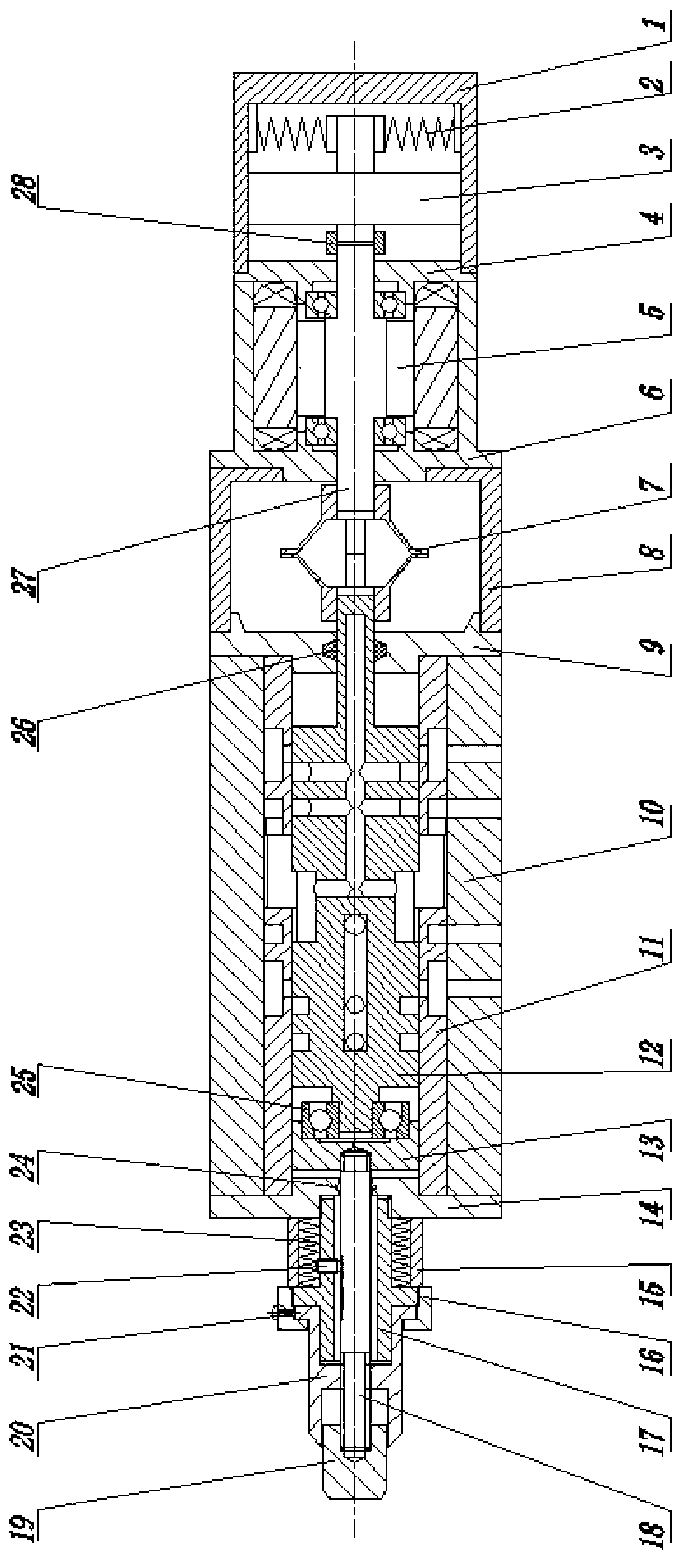

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

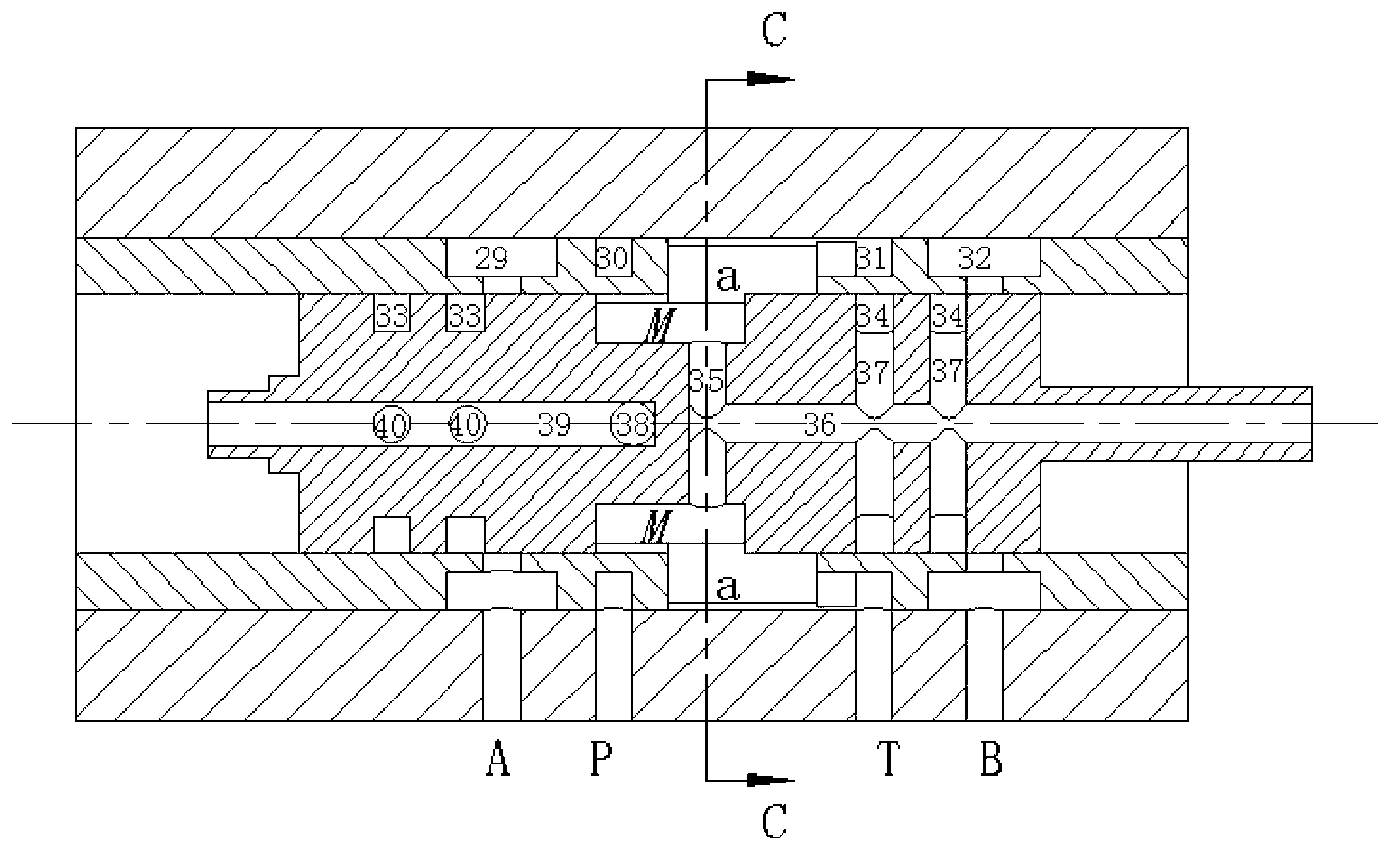

[0021] as attached Figure 1~6 As shown, the return spring 2 keeps the spool 12 at zero position, and the angular displacement sensor 3 measures the size of the rotation angle to realize closed-loop control. The 5 shafts of the electro-mechanical conversion device are directly connected with the valve core 12 through the elastic coupling 7, so the dynamic performance is better.

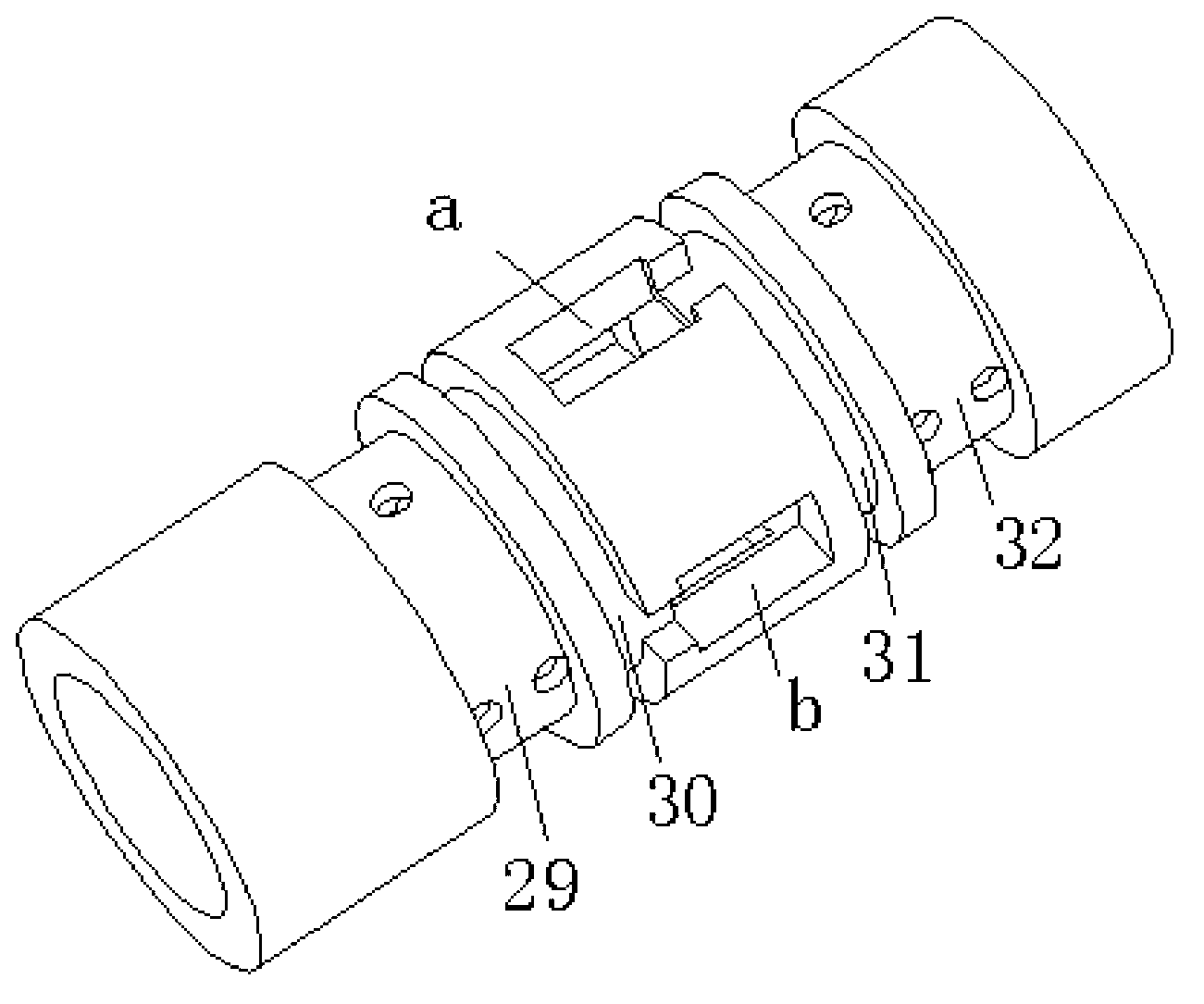

[0022] When the rotary valve is working, the on-off condition of the oil circuit can be checked by the attached Figure 5 , 6 illustrate. as attached Figure 6 As shown, when the spool 12 is at the zero position, the two pairs of rectangular valve ports, the low-pressure valve port a and the high-pressure valve port b, are all closed. At this time, the left and right working oil ports A and B of the rotary valve have no oil flow. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com