Automatic-feeding biomass combustion furnace

A biomass combustion furnace and automatic feeding technology, which is applied to household stoves/stoves, solid heating fuel, lighting and heating equipment, etc., can solve the problems of manual feeding, waste of time, and simplification of application fields, so as to avoid The effect of reducing carbon formation and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

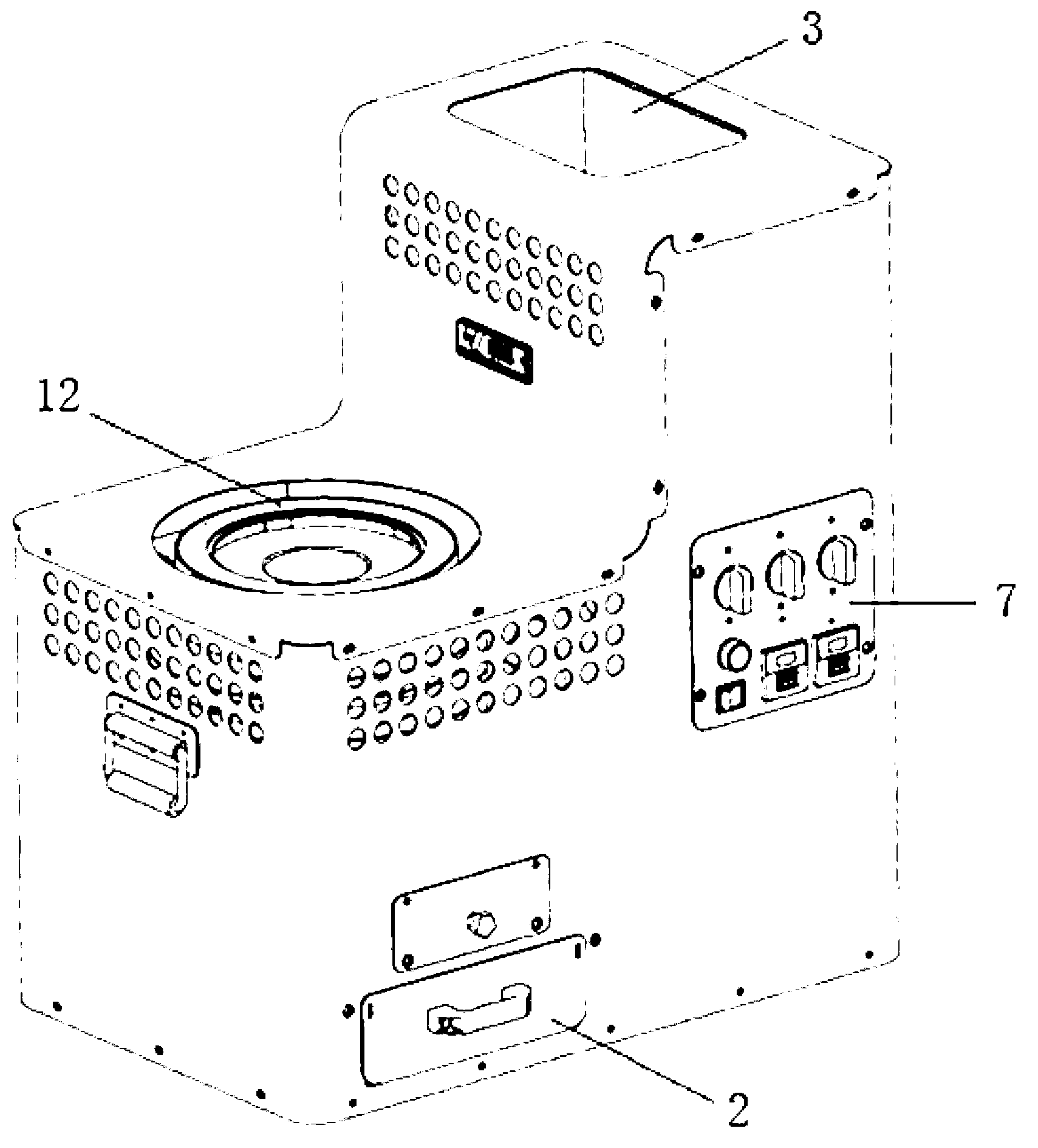

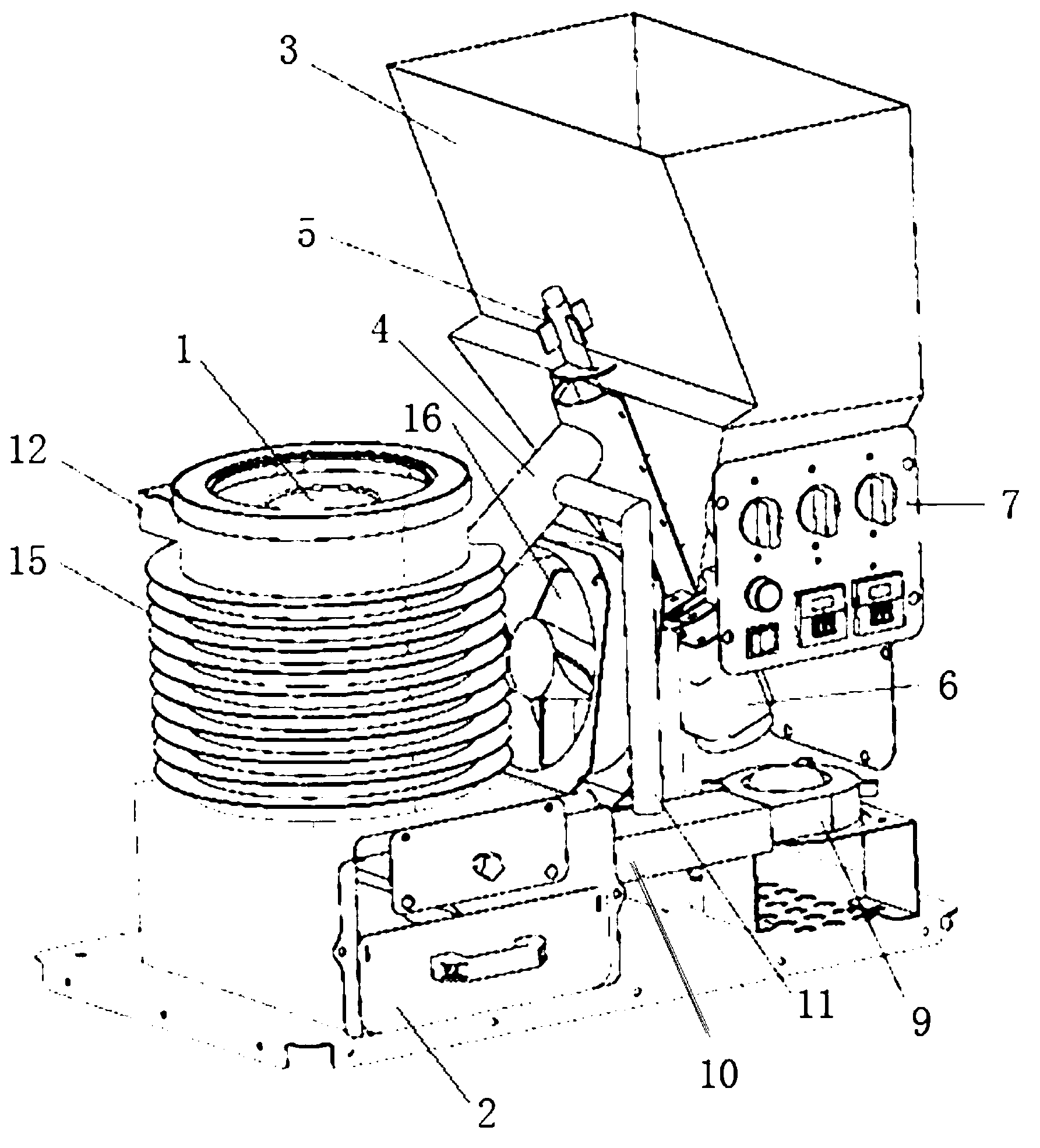

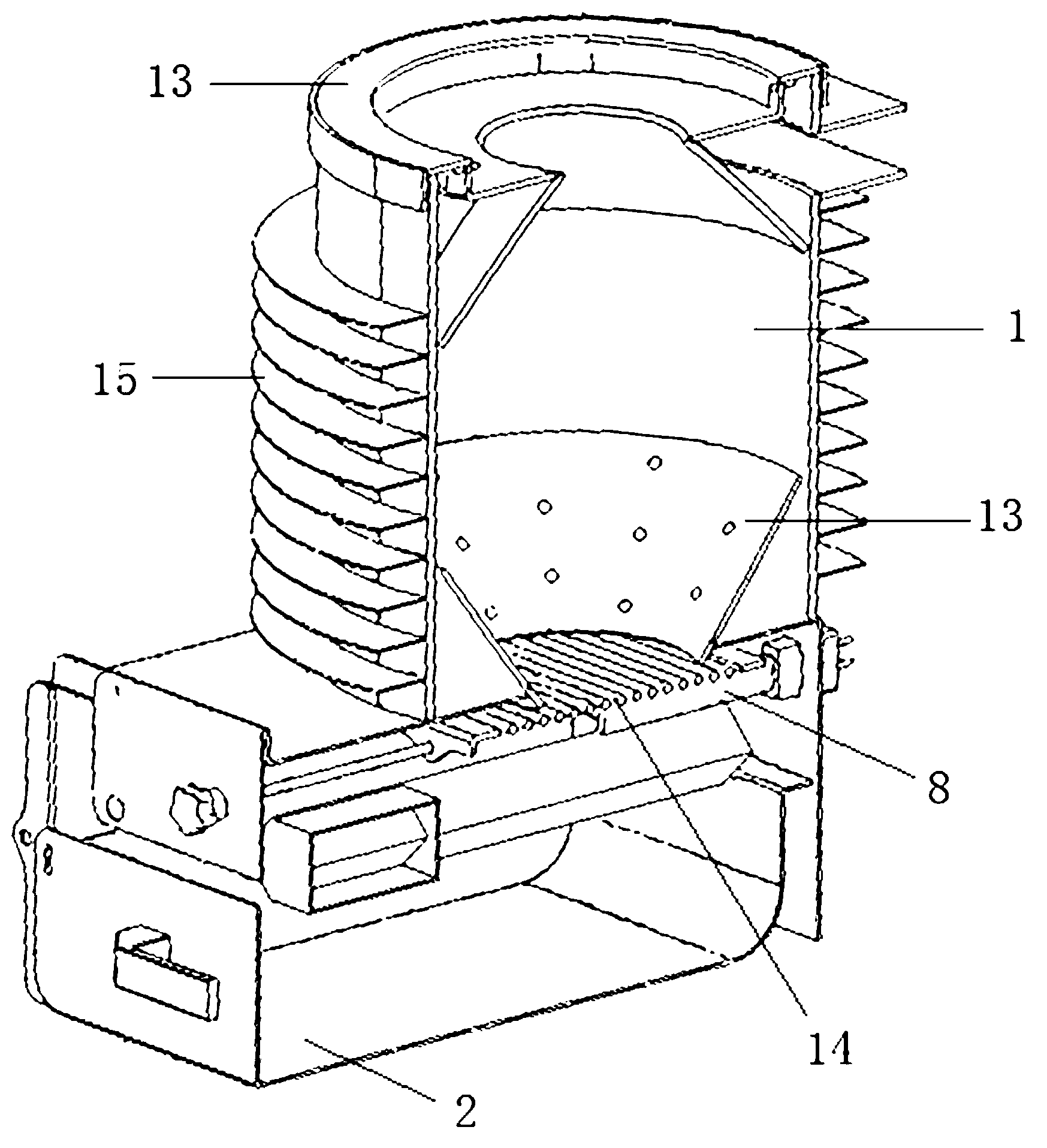

[0021] refer to Figure 1 to Figure 3 , The automatic feeding biomass combustion furnace of the present invention includes: a furnace 1 , an ash box 2 arranged below the furnace 1 and an automatic feeding device communicated with the furnace 1 . Specifically, the automatic feeding device includes: a hopper 3, a feeding cylinder 4 connecting the hopper 3 and the furnace 1, a feeding conveying auger 5 arranged at the feeding port of the feeding cylinder 4, and driving the feeding conveying auger 5 to rotate motor 6, and a circuit controller 7 for controlling the work of the motor 6.

[0022] As a preferred solution, the automatic feeding biomass combustion furnace of the present invention also includes an ignition rod 8 . Ignition rod 8 is arranged on the bottom of furnace 1, is electrically connected with circuit controller 7, presses th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com