Opposite-rotation-direction combined rotor in heat exchange tube

A heat exchange tube and combined technology, applied in the field of different rotation combined rotors, can solve the problems of large driving torque, limited degree of fluid disturbance, damage to the inner wall of heat exchange tubes, etc., to increase tangential motion and turbulent flow, reduce Effect of thin boundary layer thickness, enhanced shear flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

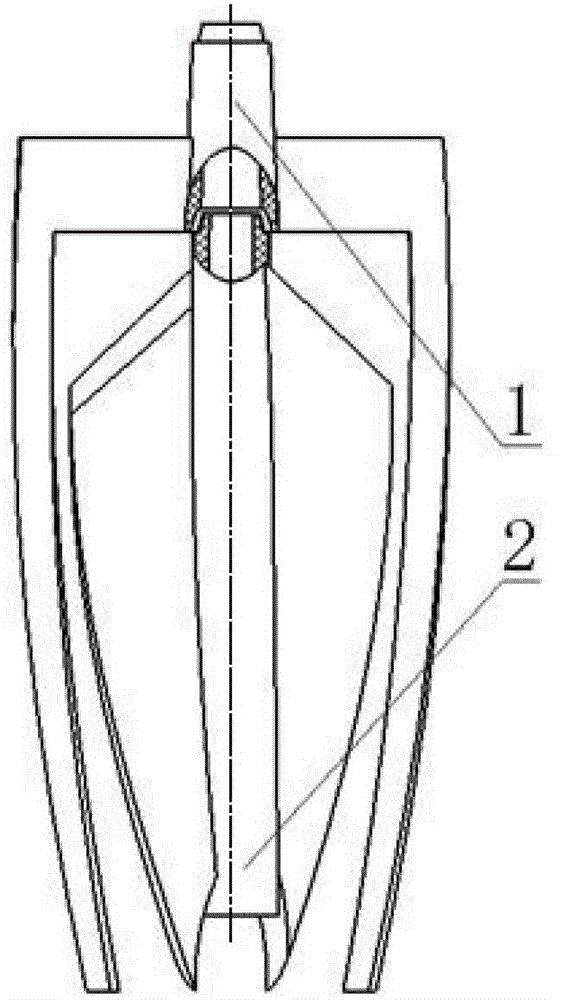

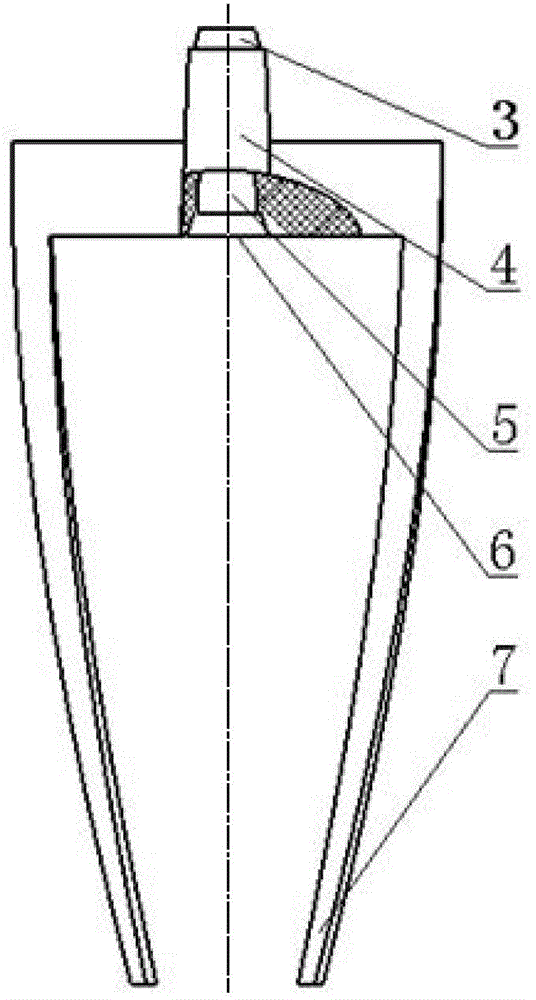

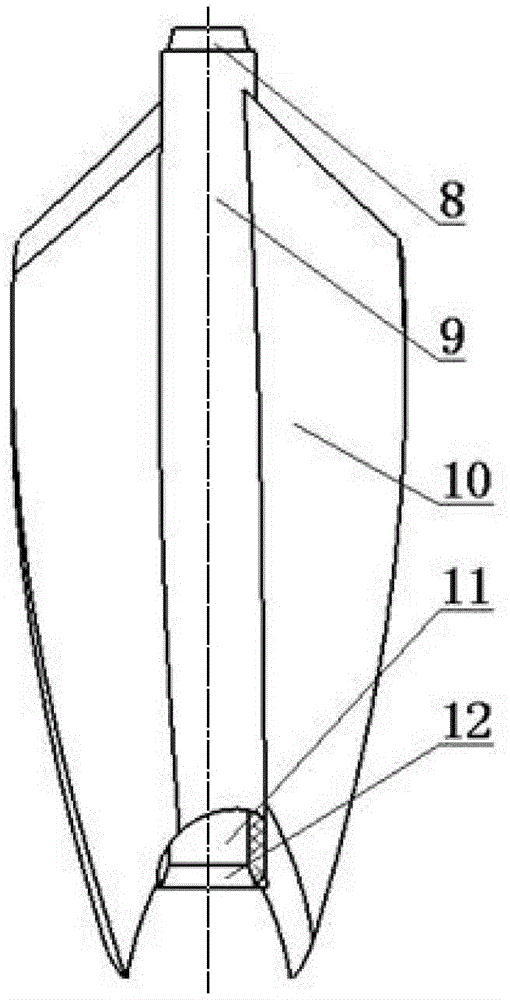

[0023] Such as Figure 4As shown, the present invention relates to an implementation method of a combined rotor with different rotation directions in a heat exchange tube. 16. Several rotors are connected in series through the rotating shaft 13, the pendant 15 is fixed at both ends of the heat exchange tube 16, and the two ends of the rotating shaft 13 are respectively fixed on the pendant 15 with the stopper 14. The rotor of the present invention is a shear rotor 1 and The turbulent rotor 2 is composed of the turbulent rotor 1, the shear rotor 1 is composed of the shear blade 7 and the shear rotor hollow shaft 4, the turbulent rotor 2 is composed of the turbulent blade 10 and the turbulent rotor hollow shaft 9, and the shear rotor of the shear rotor 1 The hollow shaft 4 is provided with a shearing rotor ball-socket boss 3 and a shearing rotor ball-socket recess 6, and the turbulent rotor hollow shaft 9 of the turbulent rotor 2 is provided with a turbulent rotor ball-socket bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com