Method for rapidly detecting main curve of tensile strength for unidirectional stretching of solid propellant

A solid propellant, unidirectional stretching technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems that do not involve the estimation of the main curve of tensile strength of static mechanical parameters, etc., to achieve strong practicability, Simple calculation method and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Solid propellant samples are sampled from solid propellant billets.

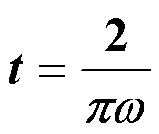

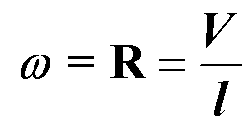

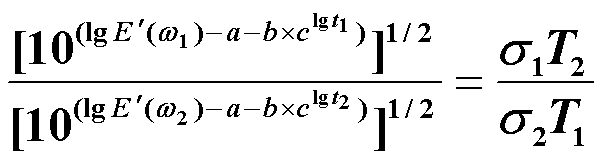

[0060] Step 1, analyzing the relationship between the dynamic storage modulus and the set dynamic frequency. Using a dynamic mechanical analyzer, measure the storage modulus E'(ω) of a solid propellant sample at a series of set temperatures and set dynamic frequencies, and obtain the reference temperature T by superposition according to the time-temperature equivalence principle s Based on the storage modulus master curve below, the relationship curve of E'(ω) - ω is obtained, figure 1 That is, the solid propellant obtained by using the dynamic mechanical analyzer at the set temperature T s =20℃ dynamic storage modulus E'(ω) master curve; and get the shift factor lgα at different set temperatures t value, for example, when the set temperature is 0°C, lgα t =1.09.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com