Method of detecting heavy metals in polyethylene plastic

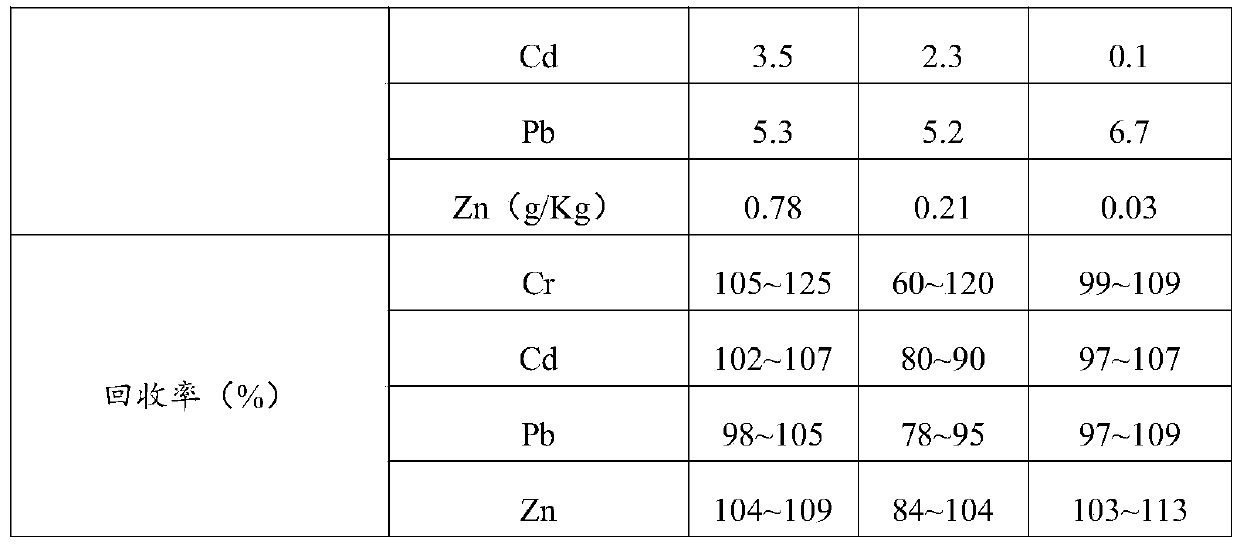

A polyethylene plastic and detection method technology, which is applied in material excitation analysis, thermal excitation analysis and other directions, can solve the problems of heavy metal recovery rate, low precision, loss of volatile elements, low efficiency of dry ashing method, etc. The effect of less volume, improved test quality, and less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

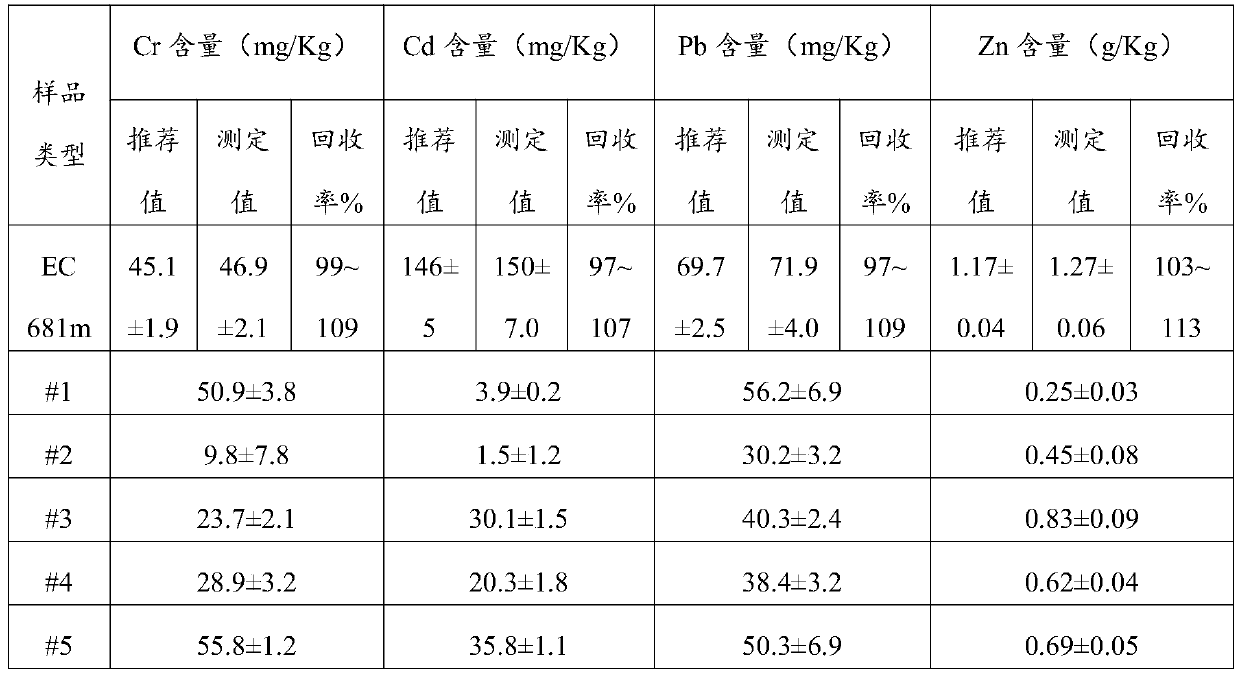

[0054] Use polyethylene plastic heavy metal standard samples -EC681m was used as the standard quality control sample, and 9 parallel samples were implemented for the standard quality control sample; 5 groups of different actual polyethylene plastic environmental samples (#1~#5) were selected, and 5 parallel samples were implemented for the polyethylene plastic environmental samples.

[0055] Accurately weigh 0.1000g samples (5 groups of different actual polyethylene plastic environmental samples (#1~#5), standard quality control samples) into a high-pressure digestion tank, add concentrated nitric acid 4mL and hydrogen peroxide (mass concentration: 30%) 2mL, let it stand for 15min, put it into the acid catcher, and pre-digest at 85°C for 15min; set the corresponding heating program for the high-pressure digestion tank according to the number of samples, and keep it at 190°C for 50min. After the digestion is completed, take out the high-pressure digestion tank, flush the acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com