Top-emitting organic electroluminescent device based on semi-transparent composite negative electrode and preparation method for top-emitting organic electroluminescent device

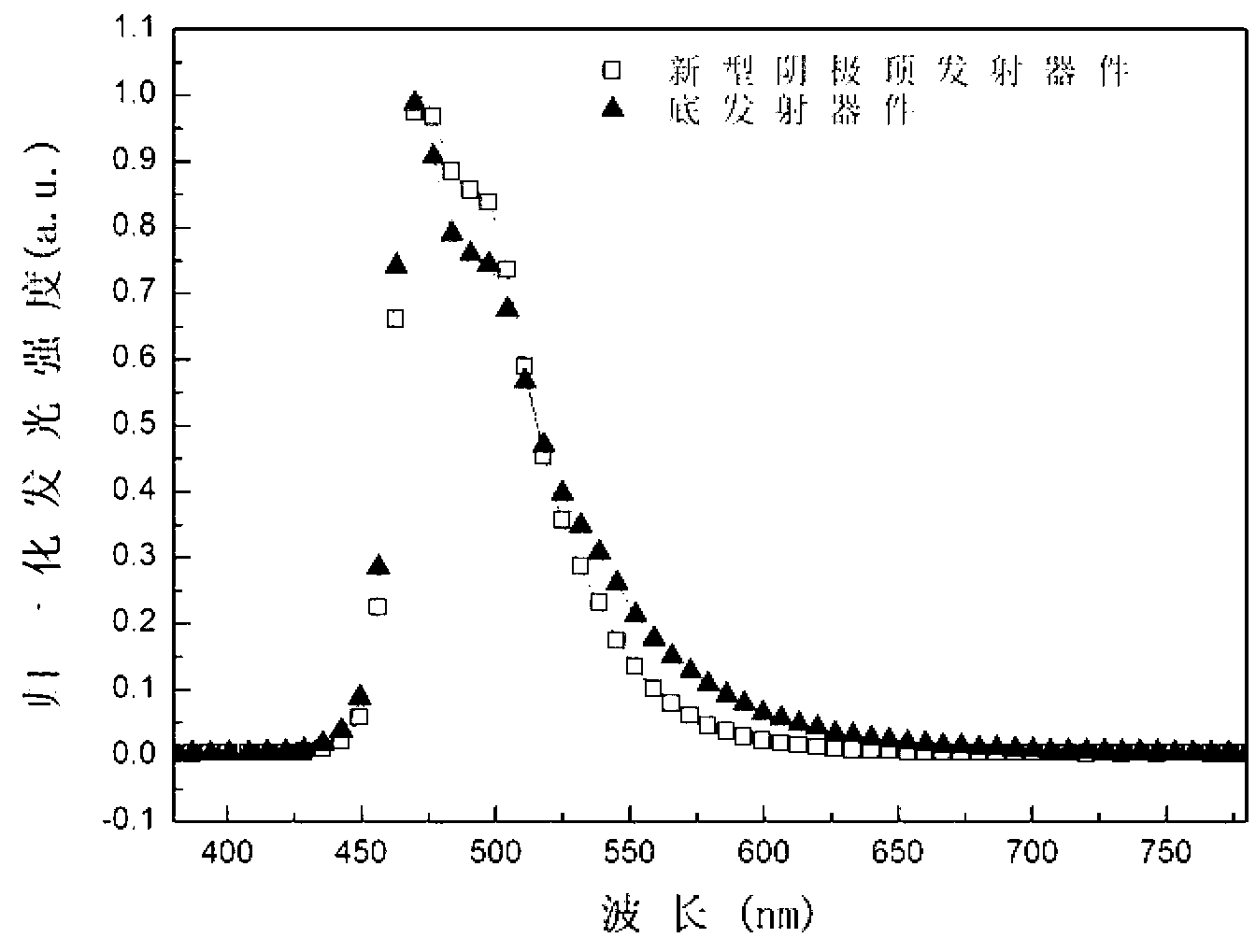

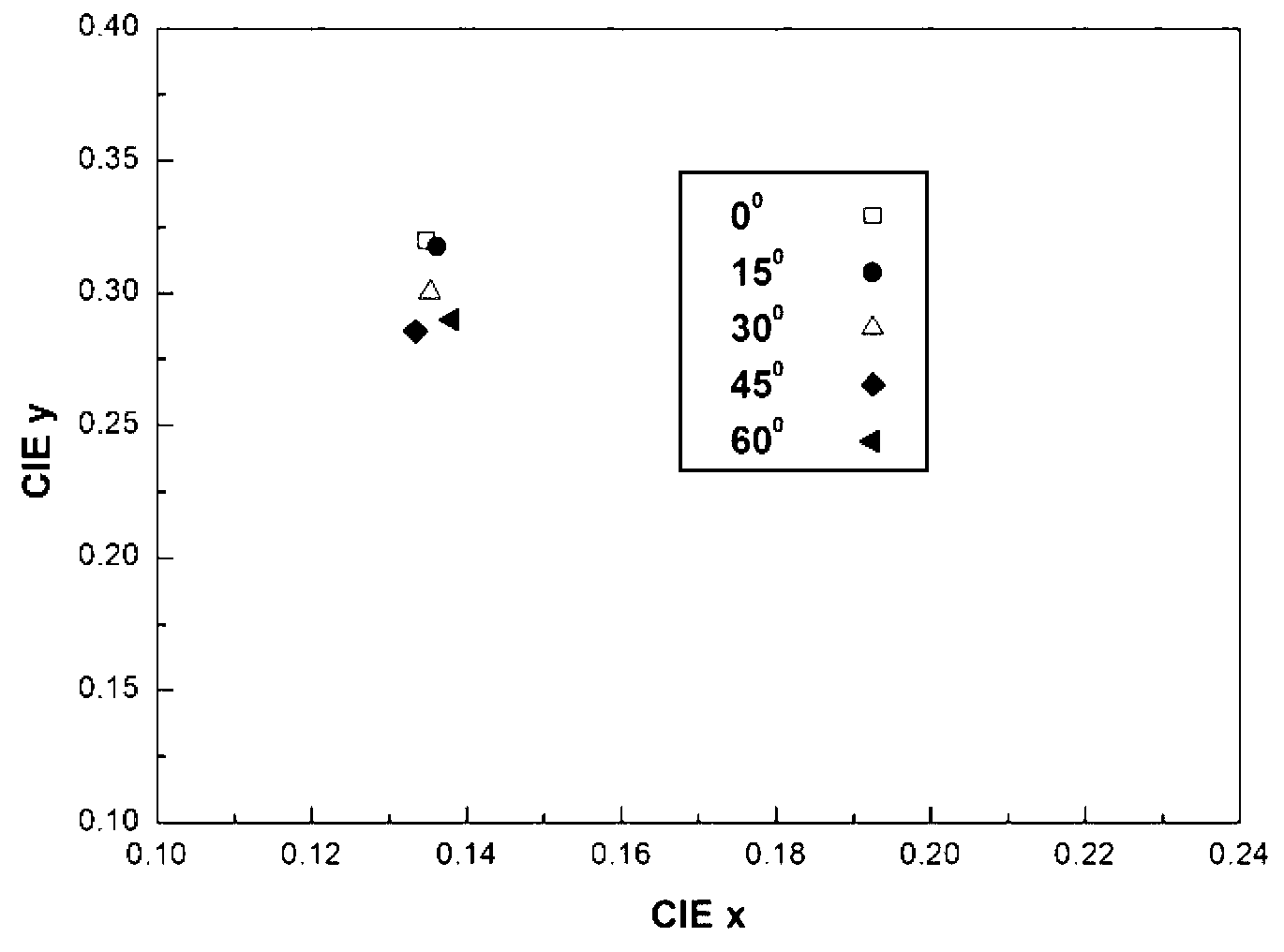

A compound cathode and top emission technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem that the spectrum affects the display or lighting effect of the device, so as to overcome the problem of angle dependence and improve angle stability , the effect of good angle stabilization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

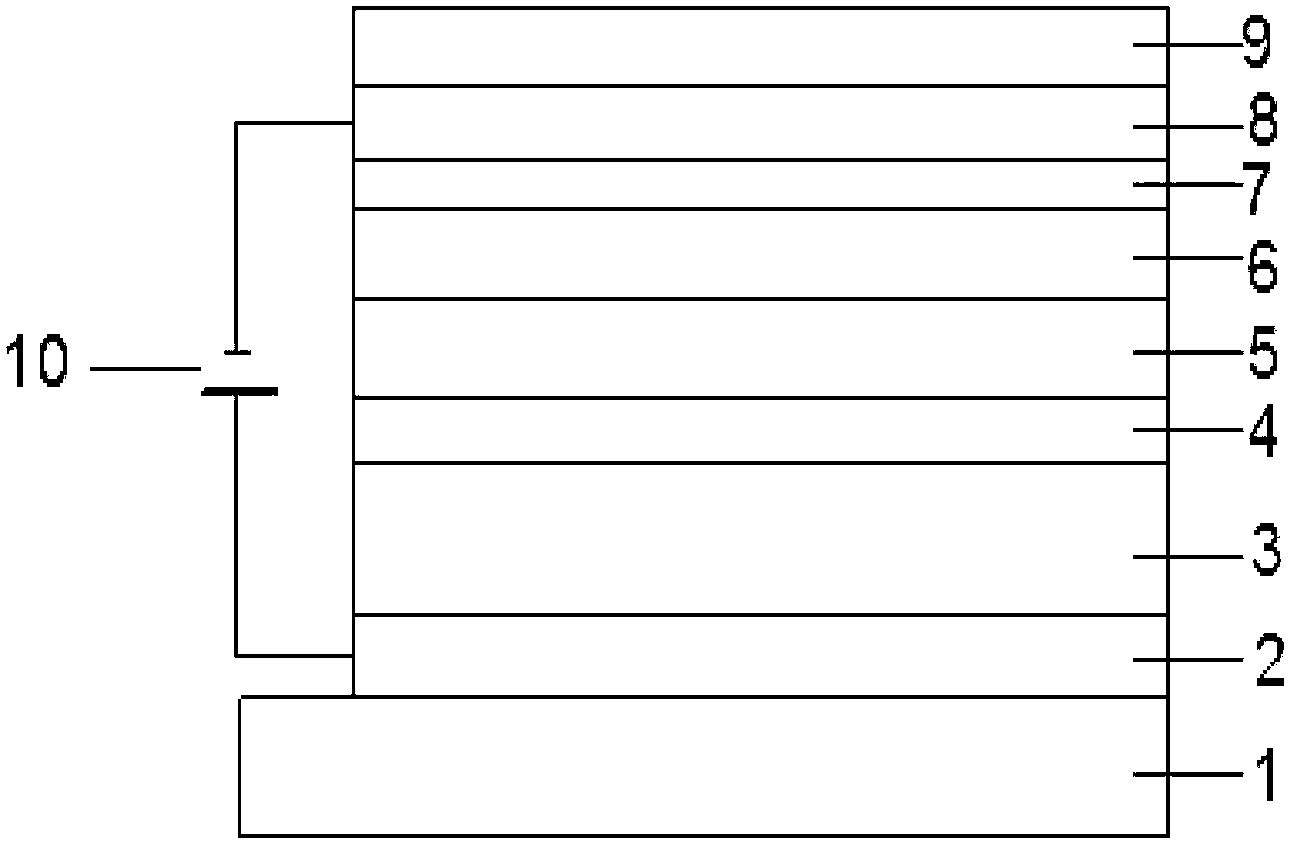

[0034] A blue top-emitting device with POAPF:8wt% Firpic as the light-emitting layer was prepared. The detailed preparation process is as follows:

[0035] [l] The glass substrate is ultrasonically cleaned with toluene, acetone, ethanol and deionized water in sequence, and then dried.

[0036] [2] Place the treated substrate in a multi-source organic molecular vapor deposition system. The system includes an organic evaporation area (10 evaporation sources) and a metal evaporation area (2 evaporation sources) in the same vacuum chamber. The areas and the evaporation sources are isolated from each other to avoid mutual pollution. The substrate can be rotated to the upper part of the organic evaporation area or the metal evaporation area to facilitate the growth of materials. The substrate is 25cm away from the evaporation source and can rotate and revolve to ensure the metal film and the uniformity of the organic film, the evaporation materials used are placed in different evapo...

Embodiment 2

[0049] Prepared with POAPF:8wt%Firpic(20nm) / POAPF:5wt%Ir(MDQ) 2 (acac)(10nm) is a white-light top-emitting device with a light-emitting layer. The detailed preparation process is as follows:

[0050] [l] The glass substrate is ultrasonically cleaned with toluene, acetone, ethanol and deionized water in sequence, and then dried.

[0051] [2] Place the treated substrate in a multi-source organic molecular vapor deposition system. The system includes an organic evaporation area (10 evaporation sources) and a metal evaporation area (2 evaporation sources) in the same vacuum chamber. The areas and the evaporation sources are isolated from each other to avoid mutual pollution. The substrate can be rotated to the upper part of the organic evaporation area or the metal evaporation area to facilitate the growth of materials. The substrate is 25cm away from the evaporation source and can rotate and revolve to ensure the metal film and the uniformity of the organic film, the evaporation...

Embodiment 3

[0064] Prepared with POAPF:10wt%Ir(ppy) 3 For a green top-emitting device with a light-emitting layer, the detailed preparation process is as follows:

[0065] [l] The glass substrate is ultrasonically cleaned with toluene, acetone, ethanol and deionized water in sequence, and then dried.

[0066] [2] Place the treated substrate in a multi-source organic molecular vapor deposition system. The system includes an organic evaporation area (10 evaporation sources) and a metal evaporation area (2 evaporation sources) in the same vacuum chamber. The areas and the evaporation sources are isolated from each other to avoid mutual pollution. The substrate can be rotated to the upper part of the organic evaporation area or the metal evaporation area to facilitate the growth of materials. The substrate is 25cm away from the evaporation source and can rotate and revolve to ensure the metal film and the uniformity of the organic film, the evaporation materials used are placed in different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com