Axial-flow type stirring device suitable for pseudoplastic fluid with yield stress

A technology of pseudoplastic fluid and stirring device, which is applied in the field of pseudoplastic fluid stirring and axial flow stirring device, which can solve the problems of reduced average shear rate of stirring tank, affecting stirring efficiency, and severe circular motion, etc. It is easy to form a dead zone, reduce the volume of the dead zone, and enhance the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

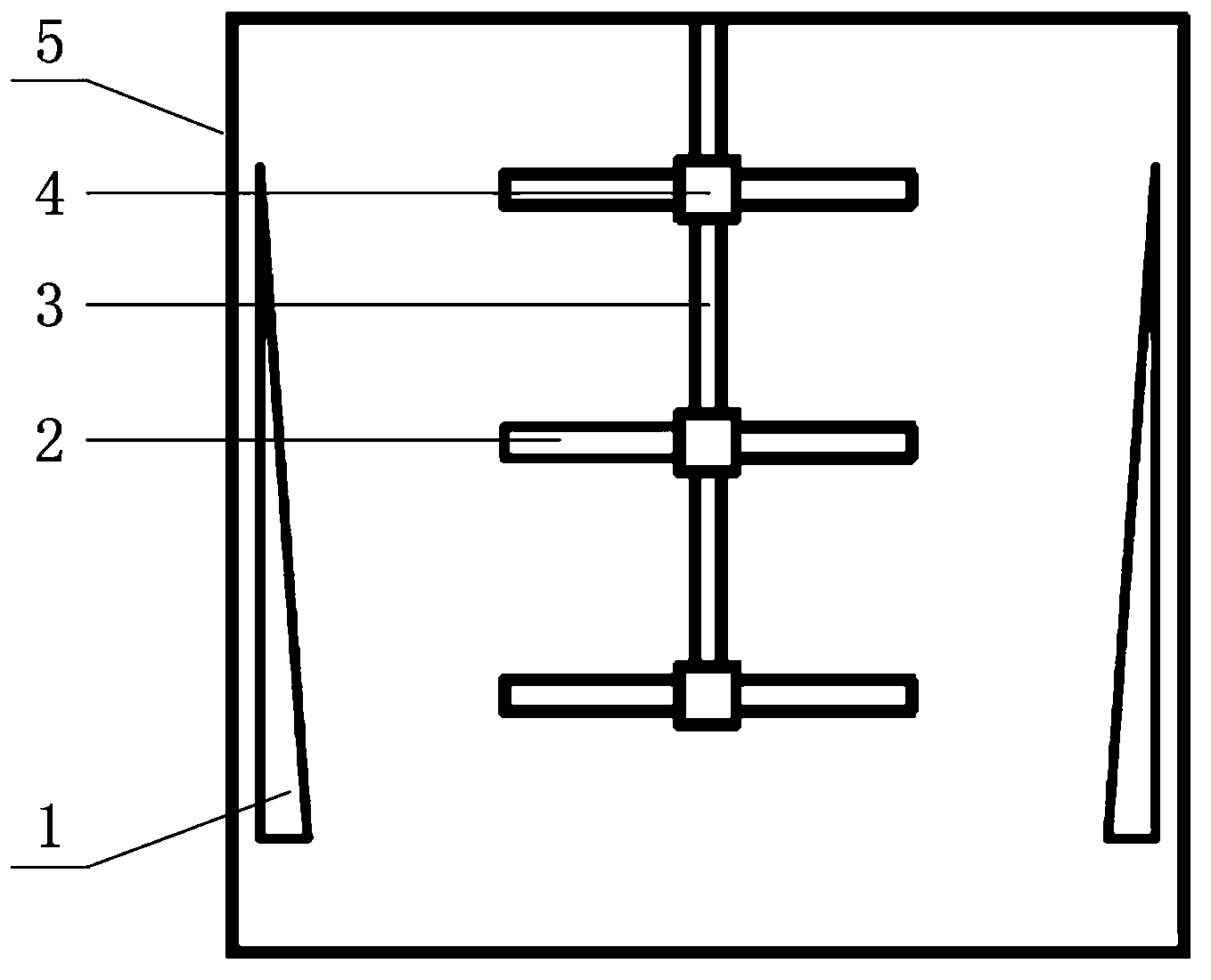

[0026] An axial flow stirring device suitable for pseudoplastic fluid with yield stress, the stirring device includes a stirring tank main body 5; the inside of the stirring tank main body 5 is provided with a triangular baffle 1 along its side wall; the triangular baffle Plate 1 has its top corner up and its bottom edge down.

[0027] The stirring tank main body 5 is cylindrical, and the triangular baffles 1 are evenly distributed along its circumference. Three to four triangular baffles 1 are evenly distributed along the circumference of the stirring tank main body 5 .

[0028] The triangular baffle 1 is a right-angled triangle, and its long right-angled side is close to and parallel to the side wall of the stirring tank main body 5 . The length of the short right-angled side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com