Preparation method of solar cell with back electrode point contact structure

A technology for solar cells and solar cells, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve problems such as the improvement of battery efficiency that cannot be ignored, and achieve the effects of reducing losses, simplifying the operation process, and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

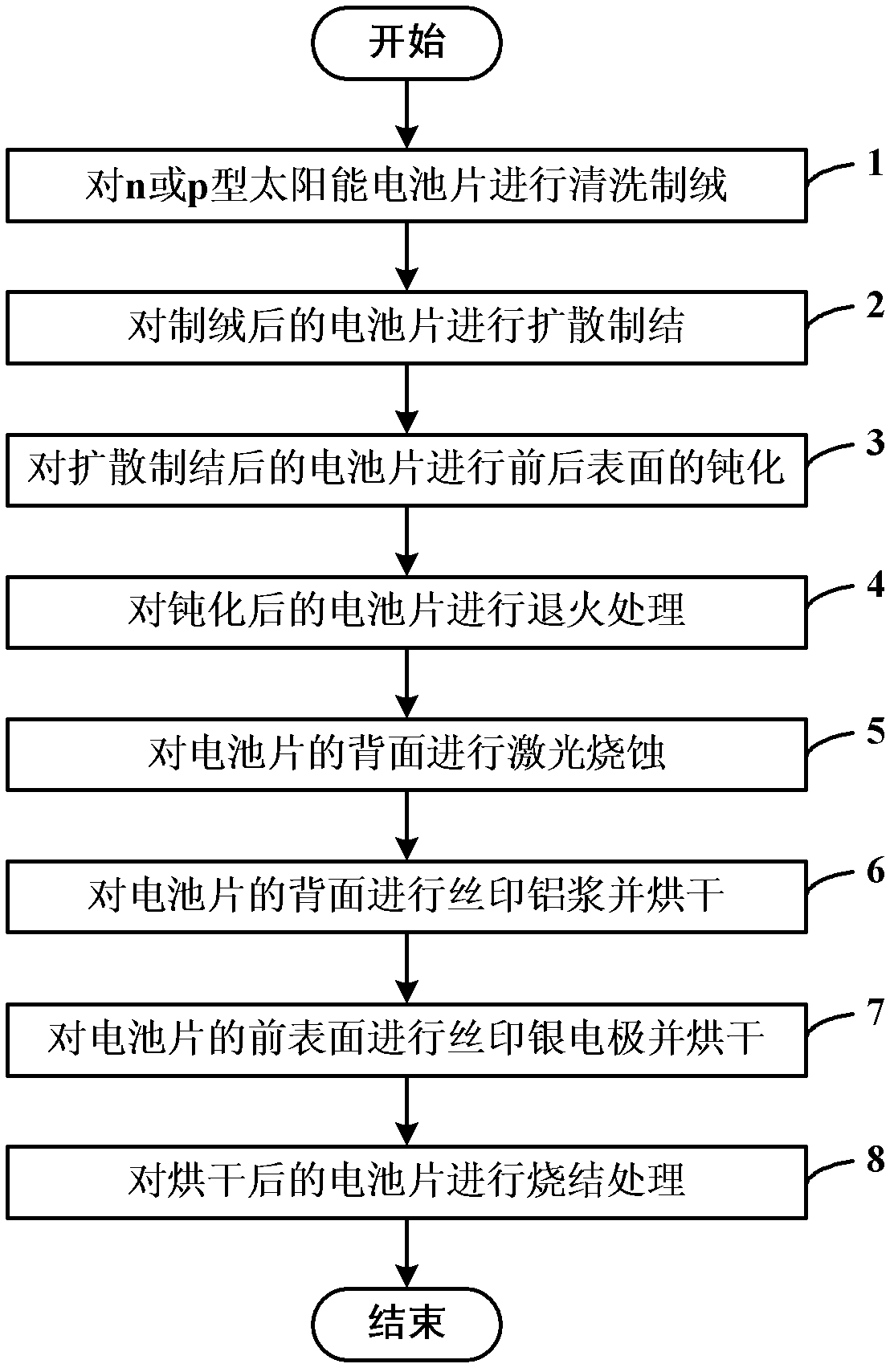

[0035] Such as figure 1 as shown, figure 1 It is a flowchart of a method for preparing a solar cell with a back electrode point contact structure according to an embodiment of the present invention, the method includes the following steps:

[0036] Step 1: cleaning and texturing n or p type solar cells;

[0037] Step 2: Diffusion and knotting of the textured cells;

[0038] Step 3: Passivate the front and rear surfaces of the diffused solar cells;

[0039] Step 4: annealing the passivated cells;

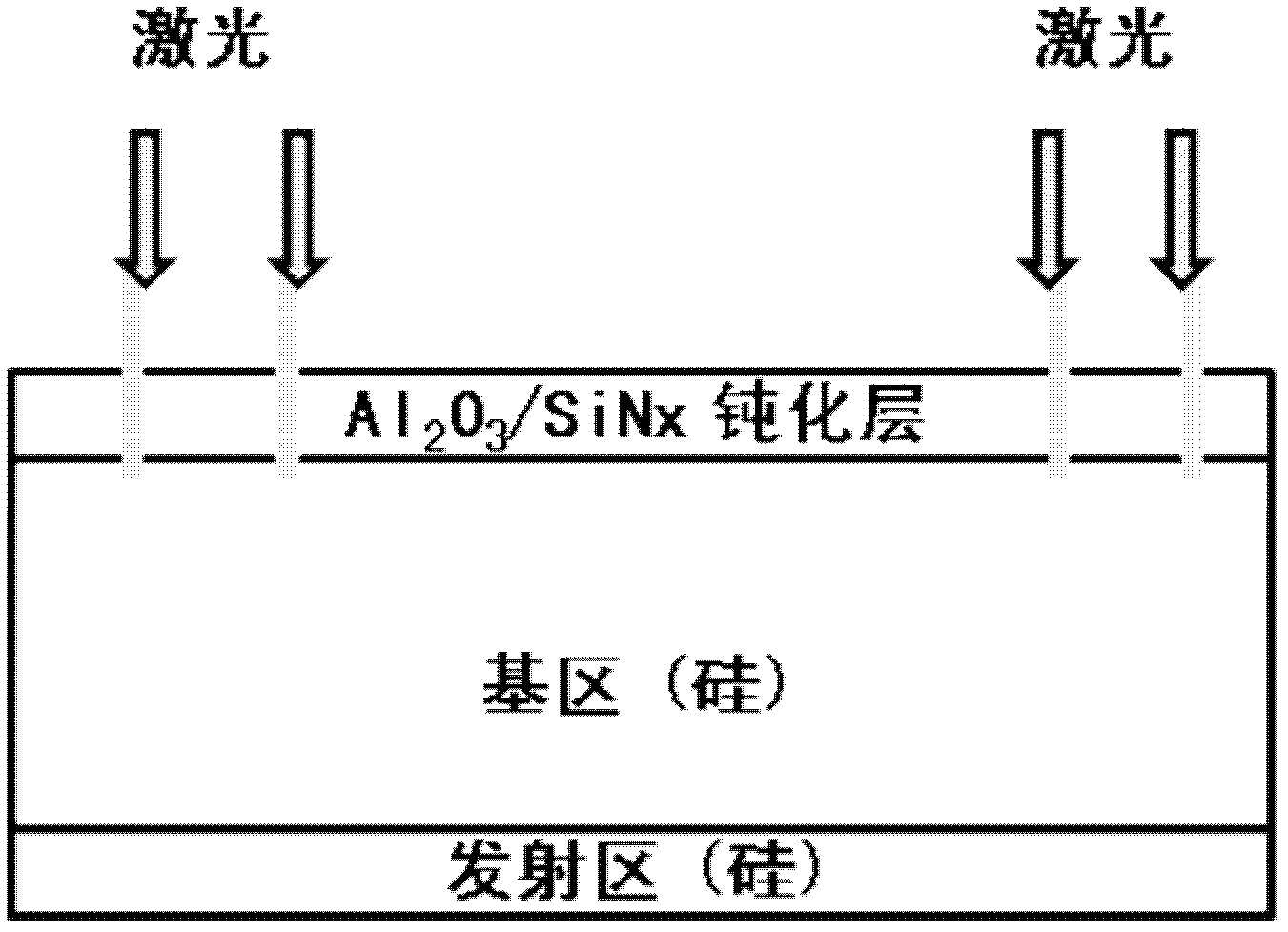

[0040] Step 5: Perform laser ablation on the back of the cell;

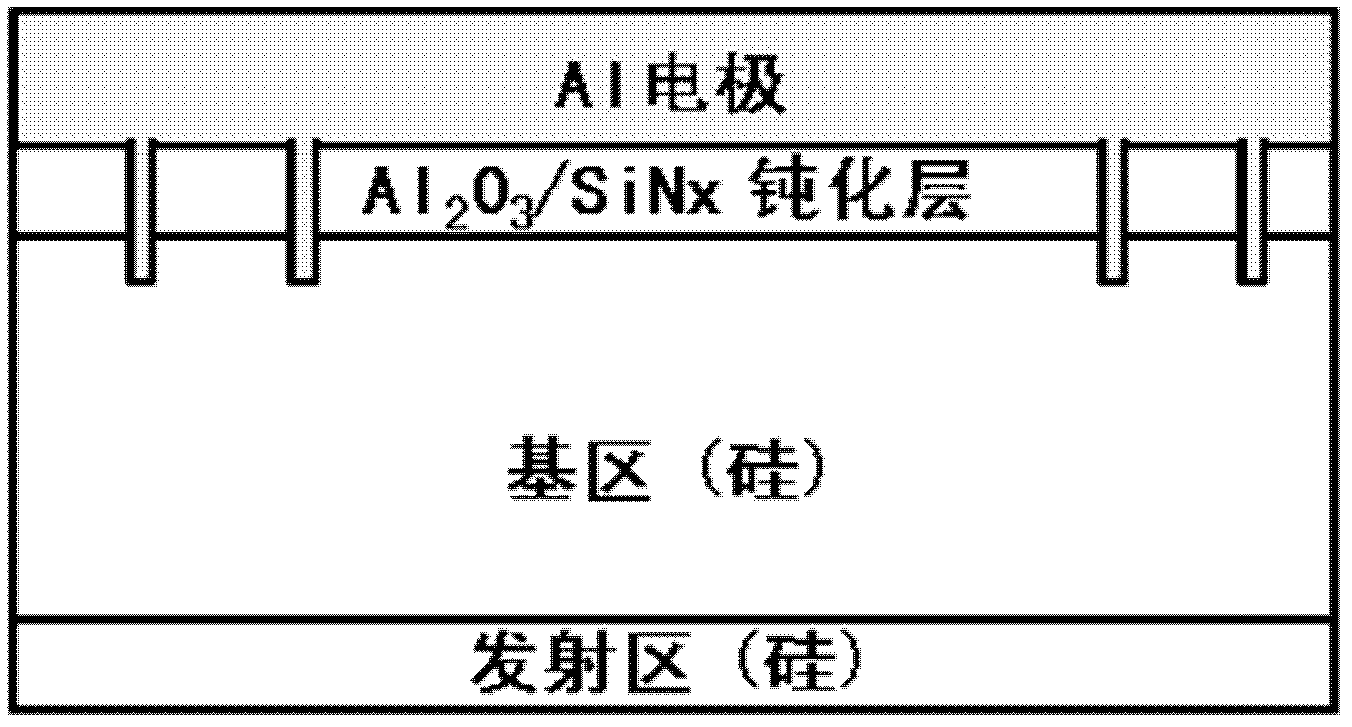

[0041] Step 6: Screen-print aluminum paste on the back of the cell and dry it;

[0042] Step 7: Screen-print silver electrodes on the front surface of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com