Semi-final grinding process and its equipment

A grinding and process technology, applied in the field of semi-final grinding process and its equipment, can solve the problems of cement strength without any help, unfavorable output, and reduced output, so as to avoid over-grinding, reduce energy consumption, and increase output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

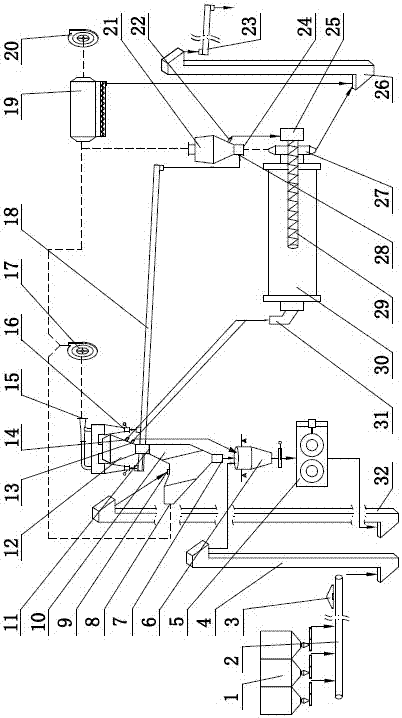

[0015] A semi-final grinding process, with reference to figure 1 , the steps are as follows: (1) Send the materials in the raw material batching station 1 into the weighing bin 6 through the conveyor 2 and the first hoist 4; (2) send the materials in the weighing bin 6 in step (1) to The amount is sent into the roller press 5, and the material cake is formed after being rolled by the roller press 5. The material cake is sent into the feed port 9 of the V-shaped powder separator 10 through the second elevator 32, and passed through the V-shaped powder separator 10. Sorting into coarse material and fine material; (3) Send the coarse material in step (2) into the weighing bin 6 in step (1), and the fine material in step (2) is mixed with the V-shaped powder classifier 10 The air flow of the air enters the combined dynamic powder separator 12, and the fine materials are sorted into large particle powder, coarse powder, medium coarse powder and fine powder through the combined dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com