Control system of solid garbage degradation device

A solid waste, control system technology, applied in the chemical industry, can solve the problem of waste overheating, hindering the flow of oxygen, and unable to monitor the moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

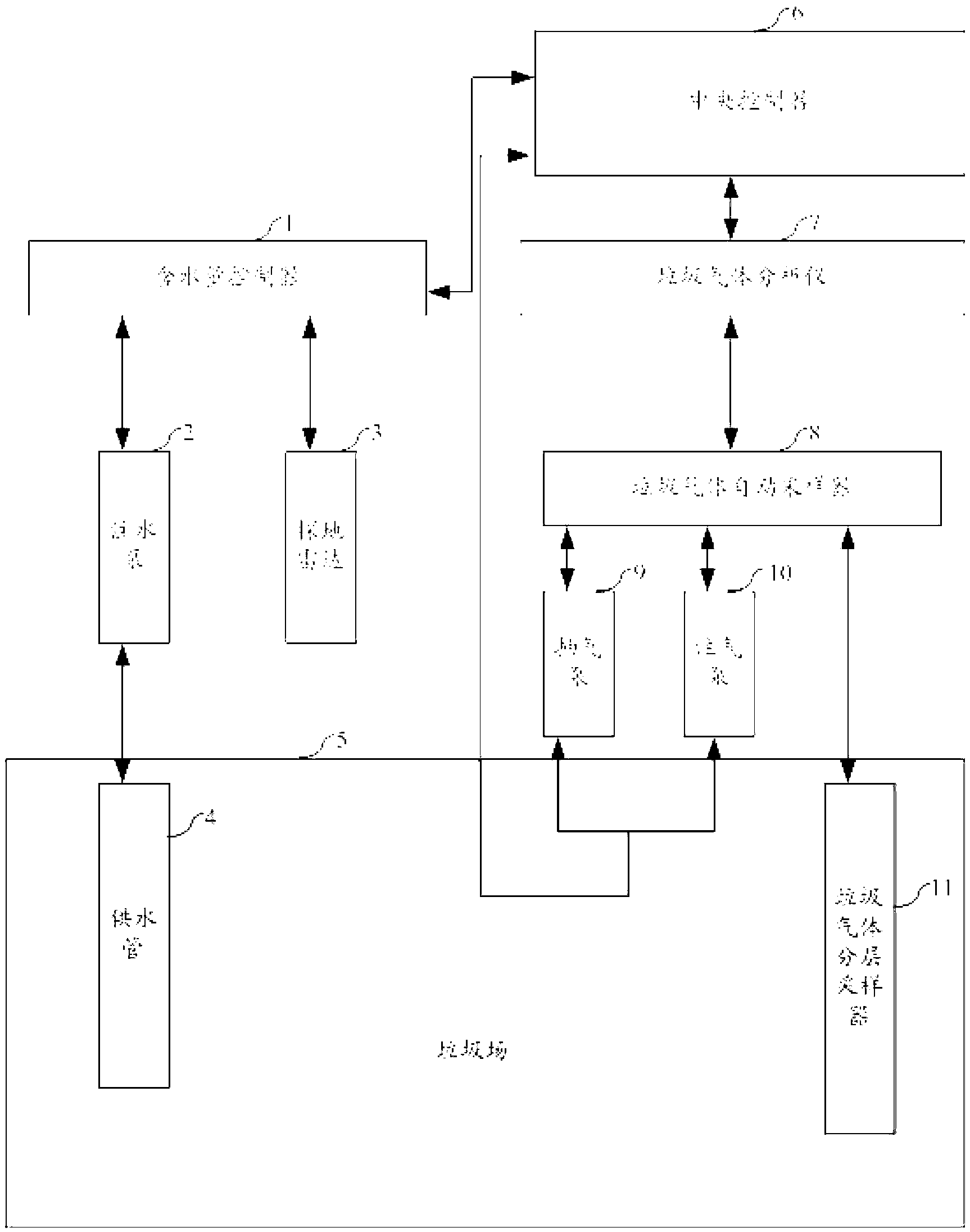

[0027] Embodiment 1 of the present invention provides a control system of a solid waste degradation device, such as figure 1 shown, including:

[0028] Garbage gas layered sampler 11, garbage gas automatic sampler 8, garbage gas analyzer 7; the output end of the garbage gas layered sampler 11 is connected with the input end of the garbage gas automatic sampler 8, and the garbage gas The output end of gas automatic sampler 8 is connected with described garbage gas analyzer 7; The output end of described garbage gas analyzer 7 is connected with;

[0029] A water supply pipe 4 provided with a plurality of water holes; the water supply pipe 4 is arranged in a garbage dump 5;

[0030] Water injection pump 2, ground penetrating radar 3, water content controller 1; Described water injection pump 2 is connected with described water supply pipe 4; Described ground penetrating radar 3 is connected with the input end of described water content controller 1; Said water content controller...

Embodiment 2

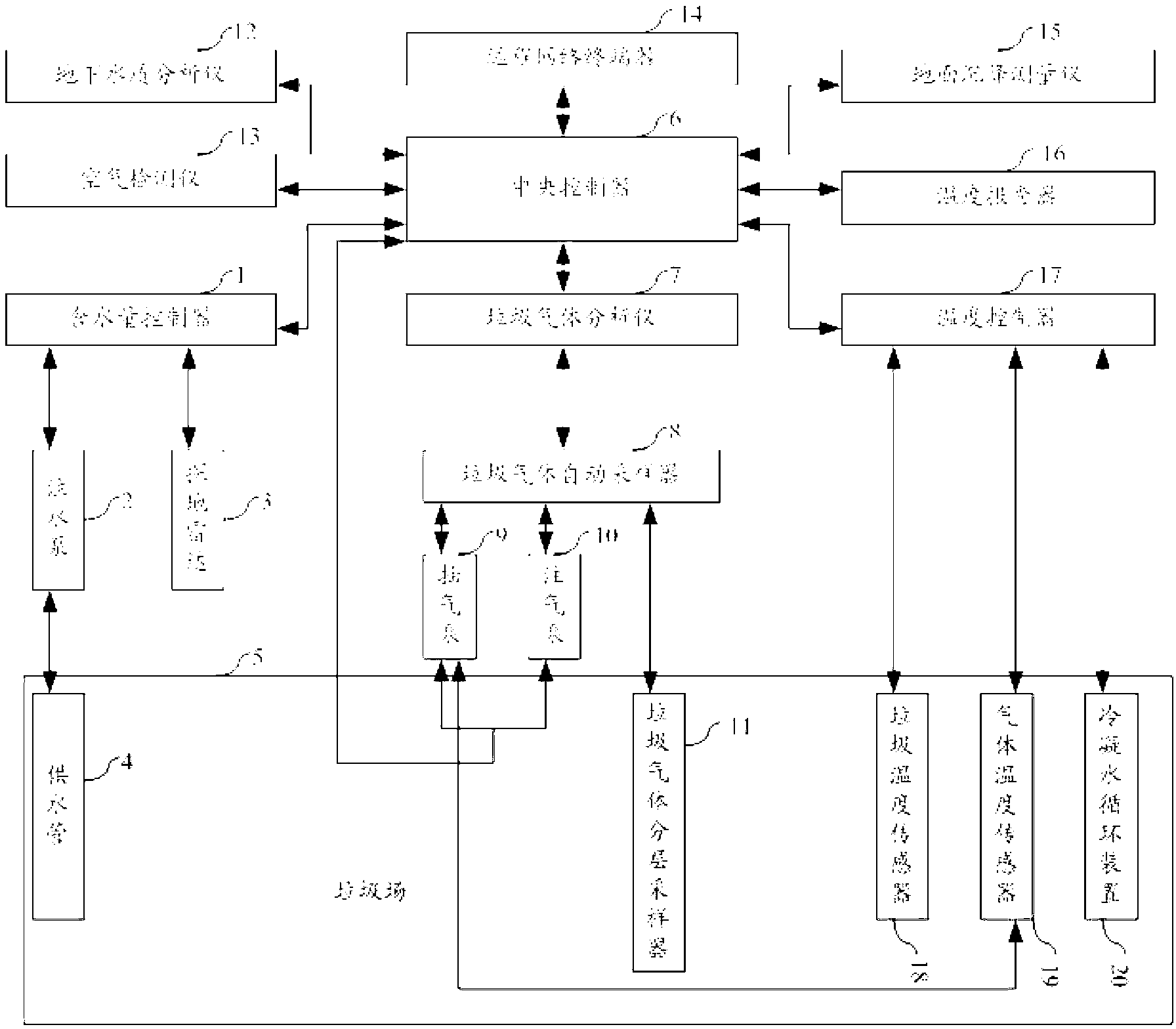

[0039] The control system of another solid waste degradation device provided in Embodiment 2 adds the following structure on the basis of Embodiment 1:

[0040] Such as figure 2 As shown, it also includes a ground subsidence measuring instrument for detecting the level of the garbage dump 5, a garbage temperature sensor 18, a gas temperature sensor 19, a temperature controller 17, a temperature alarm 16, an underground water quality analyzer 12, an air detector 13, and a remote network terminal Device 14, condensed water circulation device 20;

[0041] The garbage temperature sensor 18 is arranged in each detection point in the garbage dump 5; the gas temperature sensor 19 is arranged at the pump mouth of the air pump 9;

[0042] The garbage temperature sensor 18 and the gas temperature sensor 19 are respectively connected to the input end of the temperature controller 17;

[0043] The temperature alarm 16 is connected with the temperature controller 17;

[0044] The conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com