Lathe used for processing hard contact lenses

A technology of contact lens and lathe, which is applied in the direction of metal processing equipment, metal processing machinery parts, turning equipment, etc. It can solve the problems of mechanical friction and wear, poor spindle stability, and difficulty in processing workpieces to meet processing requirements. Small force, smooth rotation, high precision and high frequency response to the effect of machining position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a lathe for processing hard contact lens. The present invention will be further described below in conjunction with accompanying drawing.

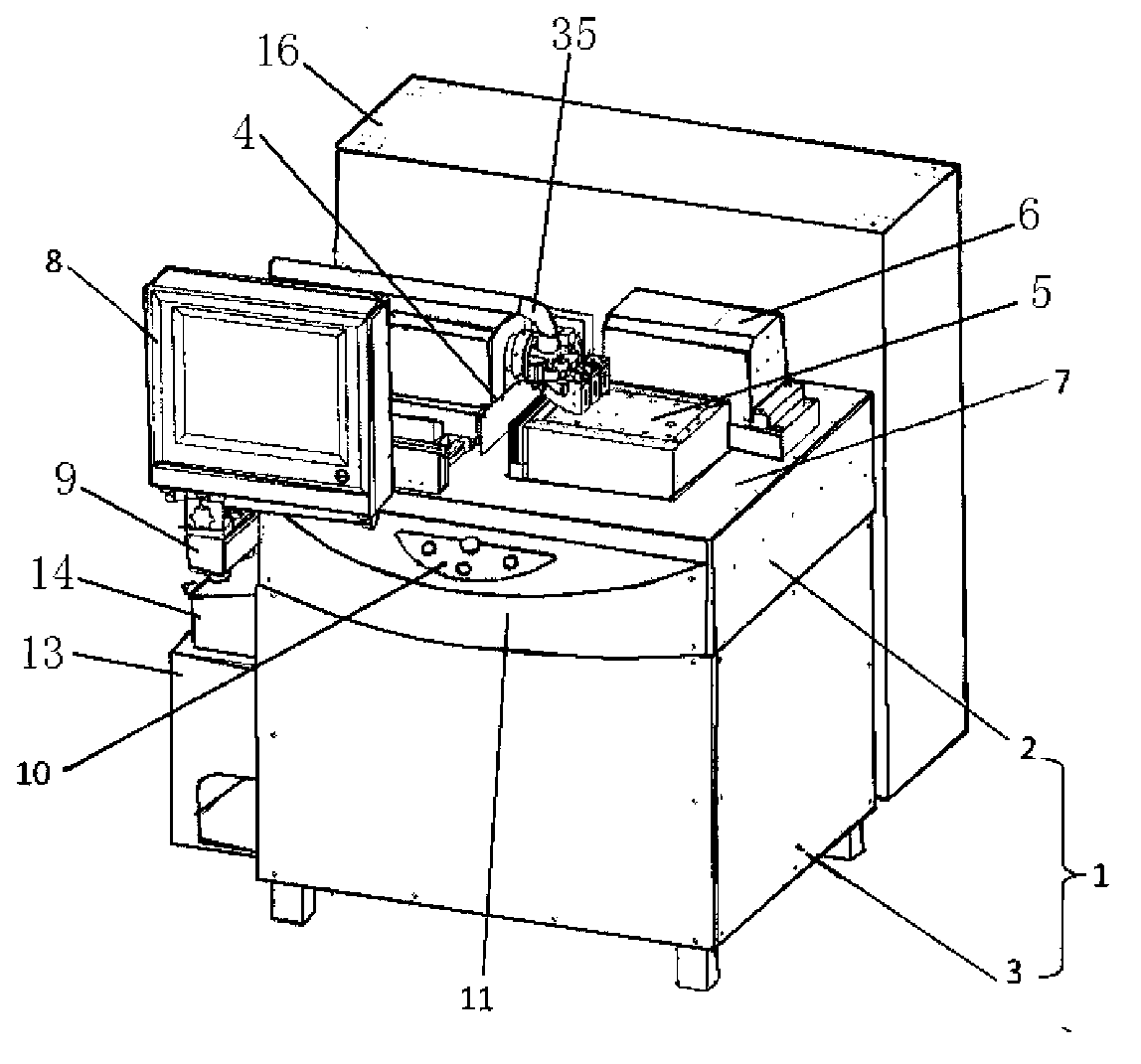

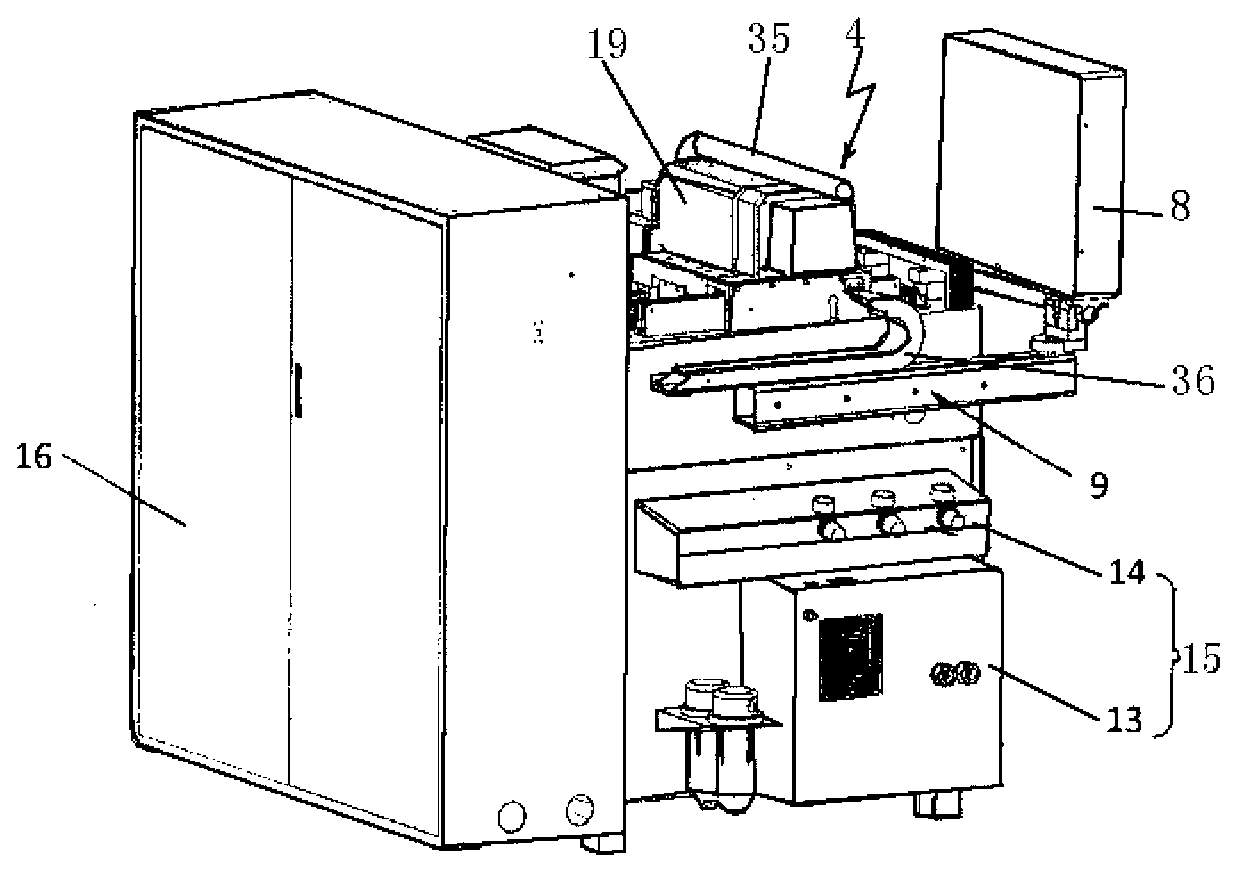

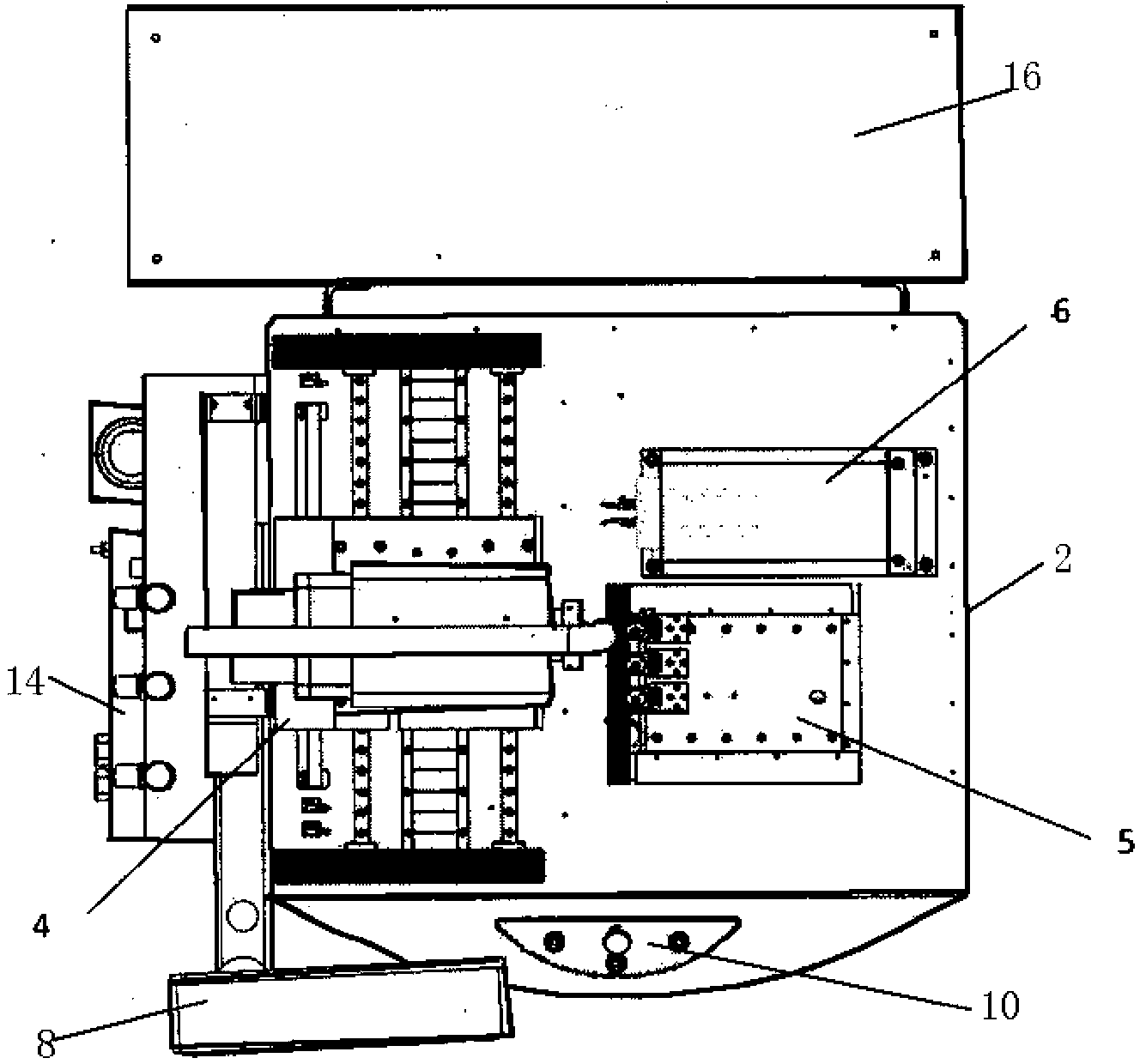

[0019] exist figure 1 , figure 2 with image 3 In the shown schematic diagram of the structure of the lathe for hard contact lenses, the fast knife tool device 6, the common knife tool device 5, and the workpiece shaft device 4 with a transverse slider device 18 fixed on the mounting surface 7 of the granite platform 2, touch The control panel 8 is supported by the control panel support frame 9 in front of the granite platform, and the front console 10 is supported by the front console support frame 11 in front of the granite platform; an electrical control cabinet 16 is placed on the rear wall of the fuselage, and the electrical control cabinet Electrical and electronic components are installed inside. An air handling device 15 composed of a cold dryer 13 and a pressure regulating device 14 is installed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap