Method for removing bromate through ordered mesoporous carbon loaded nanoscale zero-valent iron material

A nano-zero-valent iron and mesoporous carbon technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of simple operation, simple and convenient process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

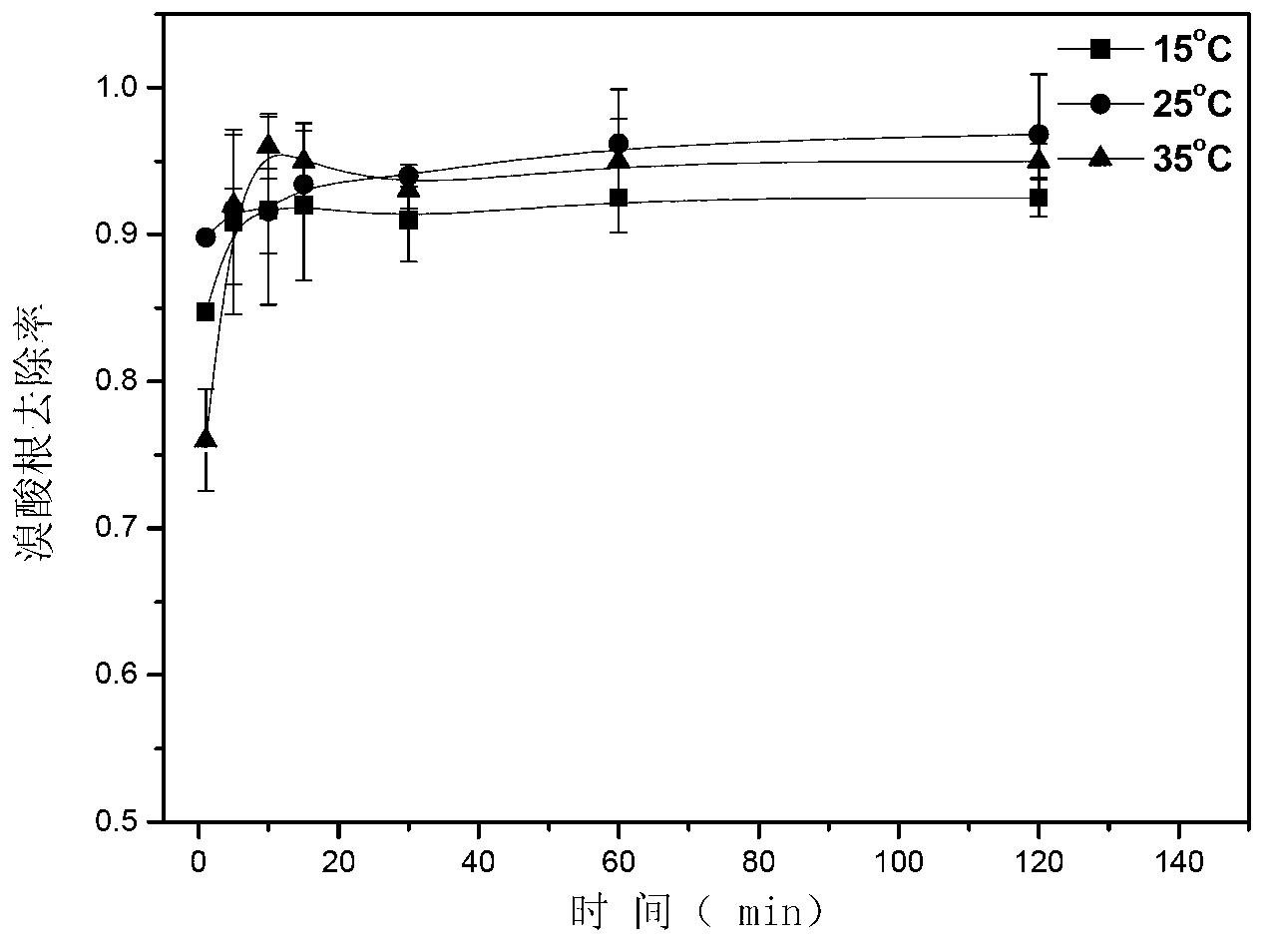

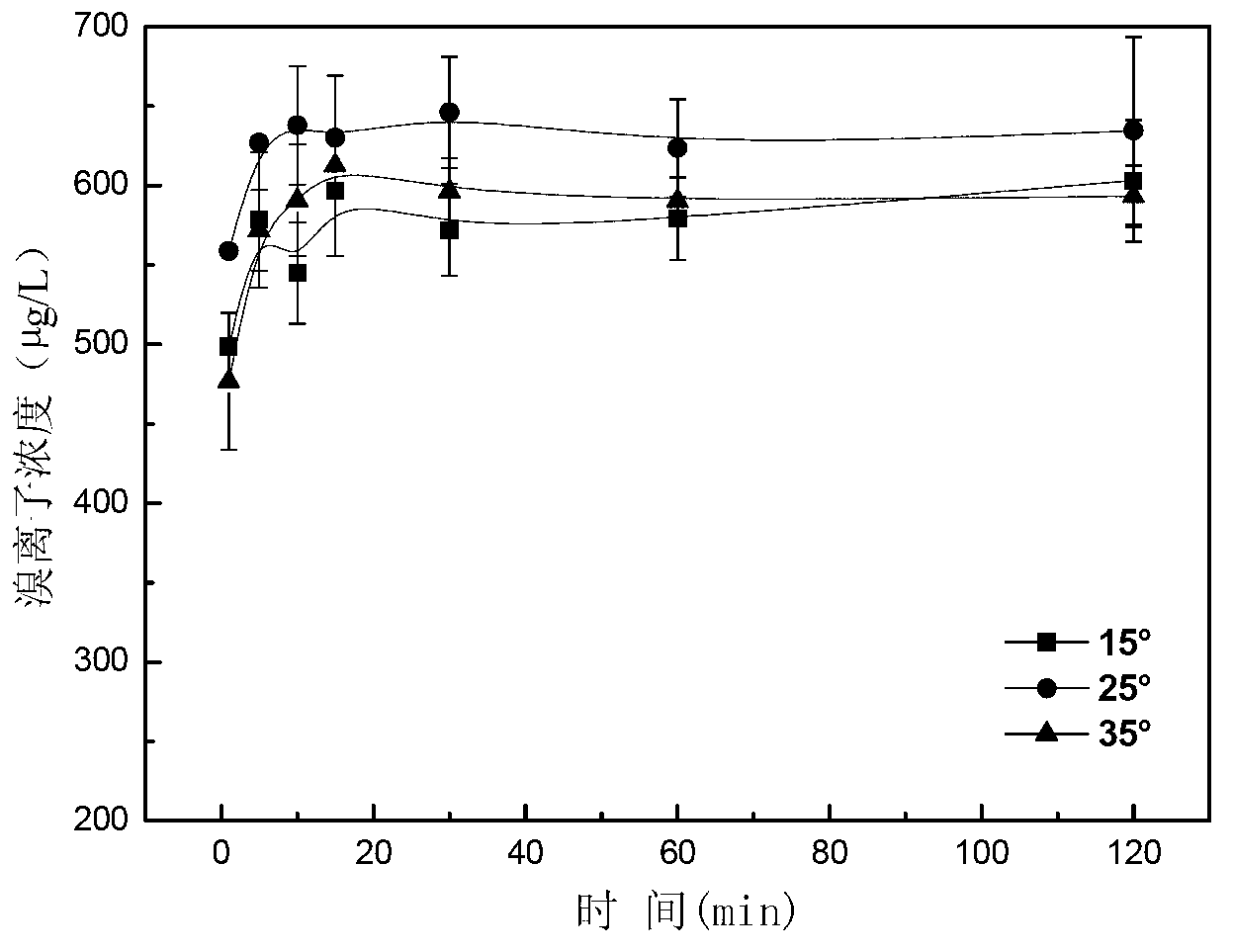

[0039] This embodiment is to verify that temperature and reaction time have the effect on BrO 3 - The effect of removal rate.

[0040] Measure 3 groups (7 parts in each group) of 100mL of 1mg / L BrO 3 - Put the solution into a 250mL Erlenmeyer flask, adjust the pH value to 5.0-6.0 with hydrochloric acid or sodium hydroxide solution, and add 0.035g of Fe with a loading rate of 25% 0 / OMC composite material, the three groups of mixed solutions were placed in constant temperature water bath oscillators with temperatures of 15°C, 25°C and 35°C for reaction, and the oscillation speed was 200rpm. Each group of solutions was reacted in turn for 1 minute, 5 minutes, 10 minutes, 15 minutes, 30 minutes, 60 minutes and 120 minutes, and the BrO in the solution was determined. 3 - and Br - concentration. The result is as figure 1 Shown, BrO 3 - The removal rate increases with the increase of the reaction time, and the removal rate reaches more than 90% after 10 minutes, and basica...

Embodiment 2

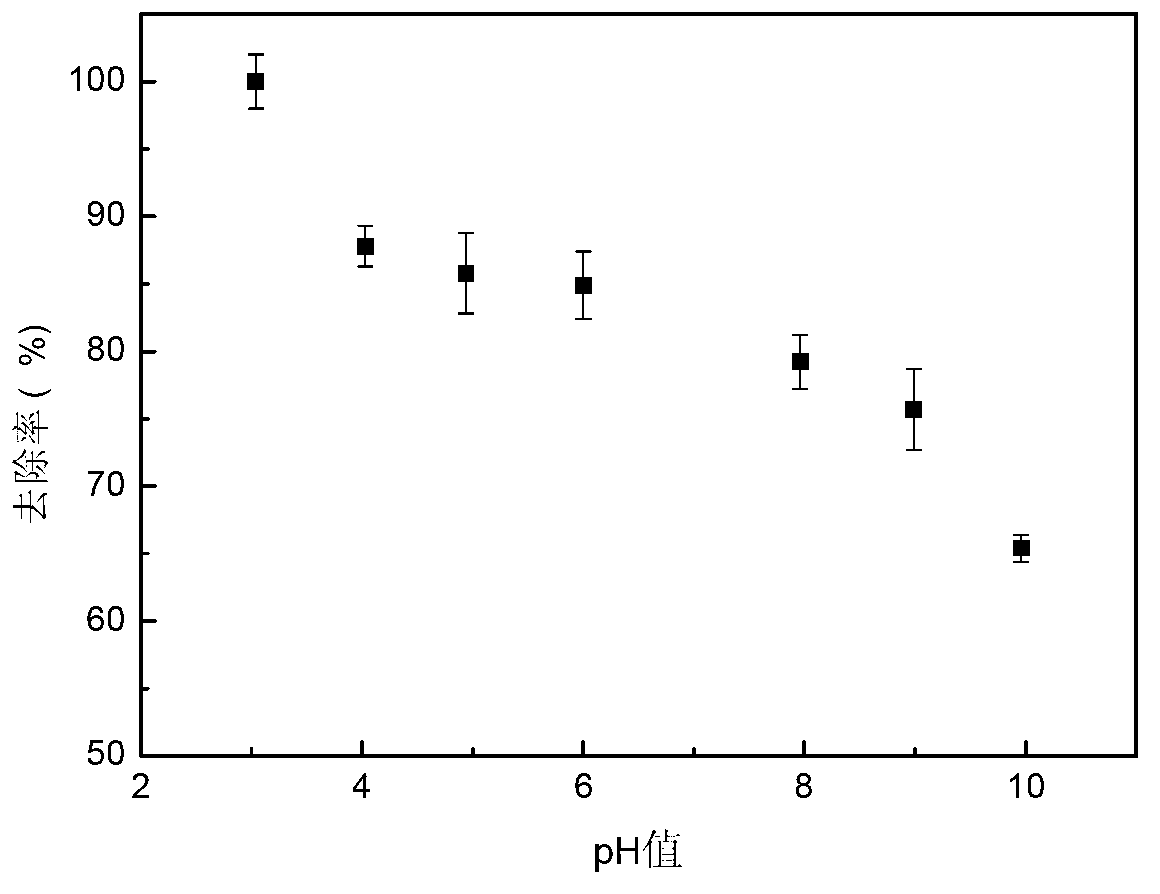

[0044] The difference from Example 1 is that this example is to verify that BrO 3 - Solution pH vs. BrO 3 - The effect of removal rate.

[0045] Take 8 parts of 100mL with a concentration of 1mg / LBrO 3 - Put the solution into a 250mL Erlenmeyer flask, use hydrochloric acid or sodium hydroxide solution to make its pH in the range of 3-10, and add 0.035g of ordered mesoporous carbon-loaded nano-zero-valent iron composite material with a loading rate of 25% respectively. The 8 parts of the mixed solution were placed in a constant temperature water bath oscillator with a temperature of 25°C for reaction, the rotation speed was 200rpm, and the oscillation mode was a loop oscillation; at 20 minutes, the BrO in the solution was measured. 3 - and Br - . The result is as image 3 As shown, it shows that the pH value has a great influence on the removal of bromate, and the smaller the pH value, the higher the removal rate. The removal rate of bromate was 100% at pH=3.0, and de...

Embodiment 3

[0047] The difference from Example 1 is that this example is to verify that BrO 3 - The initial concentration of the solution vs. BrO 3 - The effect of removal rate.

[0048] Take 4 parts of BrO 3 - 100mL solutions with concentrations of 1mg / L, 3mg / L, 6mg / L and 10mg / L were placed in a 250mL Erlenmeyer flask, and the pH was within the range of 5.0-6.0 with hydrochloric acid or sodium hydroxide solution. 0.035g of ordered mesoporous carbon-loaded nano-zero-valent iron composite material with a loading rate of 25%, put the 4 parts of the mixed solution in a constant temperature water bath oscillator at a temperature of 25°C for reaction, the rotation speed is 200rpm, and the oscillation mode is a loop type Shake; at 30 minutes, measure the BrO in the solution 3 - and Br - concentration. The result is as Figure 4 As shown, it shows that the initial concentration of bromate has a great influence on the removal rate. With the increase of the initial concentration, the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com