Medical halogenated butyl rubber stopper production method

A technology of halogenated butyl rubber and production method, which is applied in the production field of neutral salt extraction treatment of pharmaceutical halogenated butyl rubber stoppers, which can solve the problems of environmental pollution, corrosion of equipment, cumbersome manufacturing process, etc., and achieve simple process , The effect of small corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A production method of pharmaceutical halogenated butyl rubber stoppers. A certain amount of halogenated butyl rubber stoppers is immersed in an aqueous solution of sodium chloride with a concentration of 3% by mass and treated at 120° C. for 60 minutes.

[0021] The halogenated butyl rubber stopper treated with the aqueous solution of sodium chloride was rinsed with water for injection and siliconized with 350 cst of medical grade simethicone.

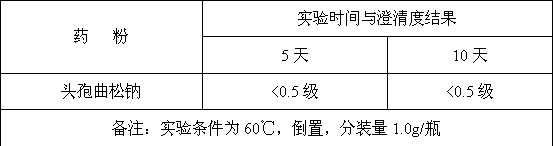

[0022] The above-mentioned siliconized halogenated butyl rubber stopper was dried at 120° C. for 60 minutes to obtain a pharmaceutical halogenated butyl rubber stopper that could meet the requirements. The results of the compatibility test between the obtained pharmaceutical halobutyl rubber stopper and ceftriaxone sodium for injection are shown in Table 1.

[0023] Table 1

[0024]

Embodiment 2

[0025] Embodiment 2: A kind of production method of medicinal halogenated butyl rubber stopper, a certain amount of halogenated butyl rubber stopper is immersed in the mixed aqueous solution of sodium chloride and acetic acid (the mass percent concentration of sodium chloride in the mixed aqueous solution is 3% , the concentration of acetic acid in the mixed aqueous solution is 0.01% by mass) at 120°C for 60 minutes.

[0026] The halogenated butyl rubber stopper treated with the mixed aqueous solution of sodium chloride and acetic acid was rinsed with water for injection and siliconized with 350 cst medical grade simethicone.

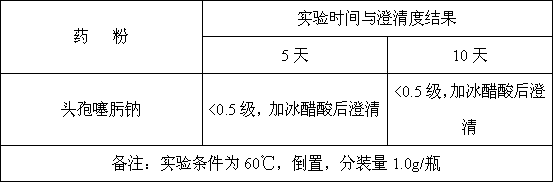

[0027] The above-mentioned siliconized halogenated butyl rubber stopper was dried at 120° C. for 60 minutes to obtain a pharmaceutical halogenated butyl rubber stopper that could meet the requirements. The results of the compatibility test between the obtained pharmaceutical halobutyl rubber stopper and cefotaxime sodium for injection are shown in Table...

Embodiment 3

[0030] Embodiment 3: A kind of production method of medicinal halogenated butyl rubber stopper, put a certain amount of halogenated butyl rubber stopper in the mixed aqueous solution of potassium chloride and acetic acid (the mass percent concentration of potassium chloride in the mixed aqueous solution is 1% , the concentration of acetic acid in the mixed aqueous solution is 0.01% by mass) at 120°C for 60 minutes.

[0031] The halogenated butyl rubber stopper treated with the mixed solution of potassium chloride and acetic acid was rinsed with water for injection and siliconized with 1000 cst of medical grade simethicone.

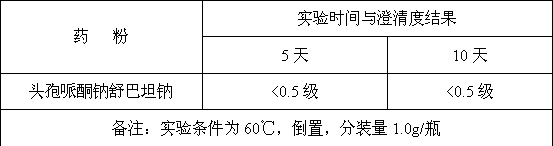

[0032] The above-mentioned siliconized halogenated butyl rubber stopper was dried at 120° C. for 60 minutes to obtain a pharmaceutical halogenated butyl rubber stopper that could meet the requirements. The results of the compatibility test between the obtained pharmaceutical halobutyl rubber stopper and cefoperazone sodium sulbactam sodium for injection ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com