A method of using straight slag washing mixed material in converter tapping

A technology of mixed materials and direct slag washing, which is applied in the direction of improving process efficiency, can solve the problems of inability to remove gas, high operating costs, and huge investment, and achieve the effects of reducing refining burden, shortening refining time, and reducing breakout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0037] The example conclusion is as follows:

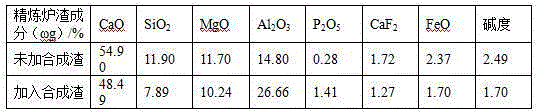

[0038] (1) The slag and slag system of the molten steel that has been directly washed by the slag washing mixed material slag changes greatly, the slag basicity drops from 2.49 to 1.70, and the ω(Al 2 o 3 ) increased by 80% and the viscosity was moderate, and the ω (FeO) in the slag decreased by 28%, which created favorable thermodynamic and kinetic conditions for desulfurization of refining slag.

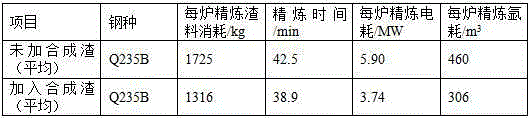

[0039] (2) The slag washing process of mixed materials for direct slag washing reduces the amount of refining slagging materials and shortens the time for arc heating slag melting. After adding the mixed materials for direct slag washing, the refining time is shortened by nearly 4 minutes on average. Finally, it is the multi-furnace continuous process of the CSP production line. Pouring provides reasonable production conditions.

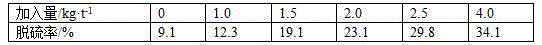

[0040] (3) After direct slag washing and mixed material slag washing, the desulfurization rate of ω[S] i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com