Refrigerating circuit for air conditioning refrigeration device performance testing device

A refrigeration circuit and equipment performance technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of limited refrigeration capacity, far less processing effect, dry friction of compressors, etc., to eliminate the gap between the thermal properties of working fluids The effect of relieving the unevenness of temperature and humidity, and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

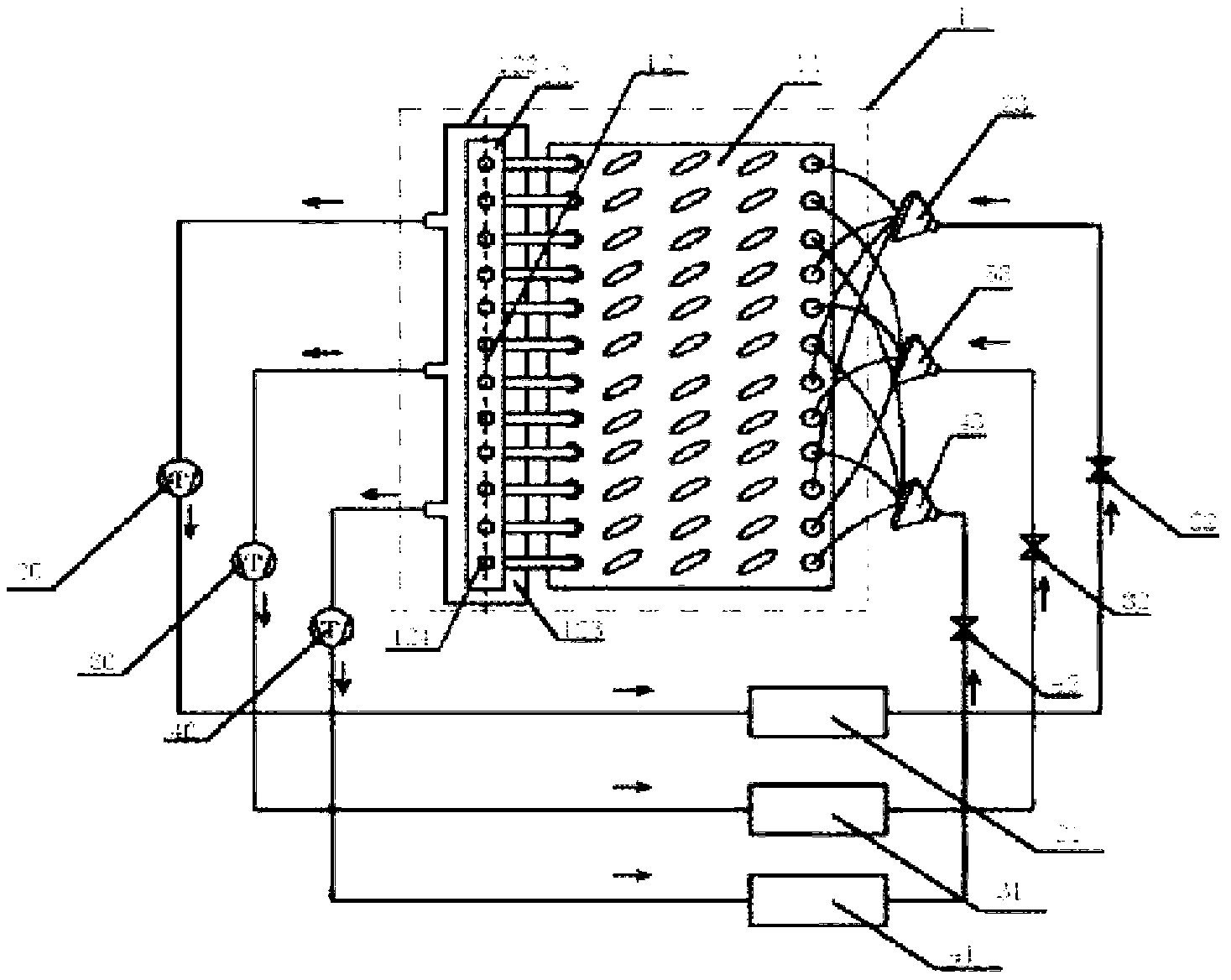

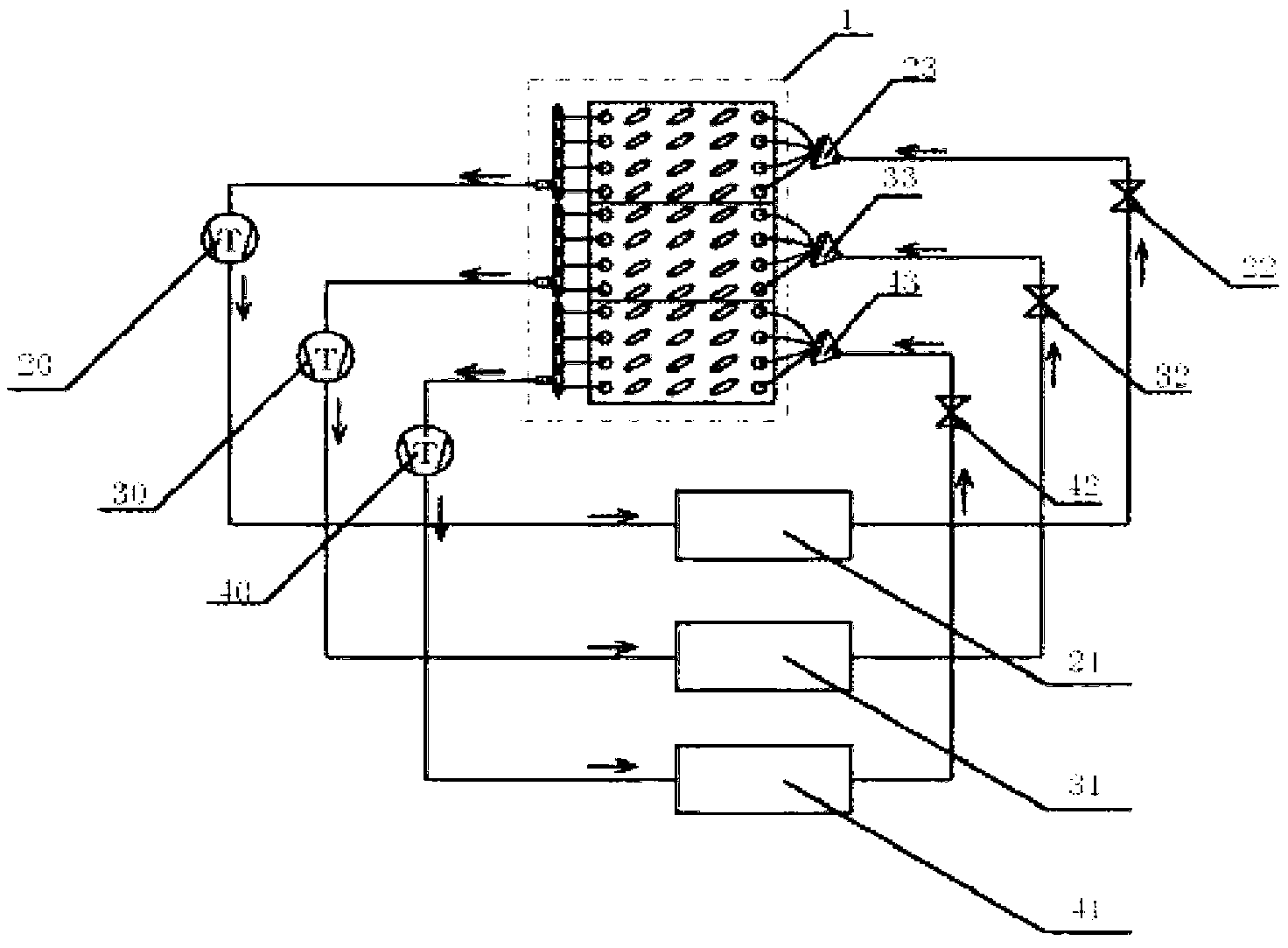

[0022] The refrigerating circuit used for the performance test device of air-conditioning and refrigeration equipment of the present invention includes an evaporator 1 and three groups of compression and condensing units arranged in parallel, each group of compression and condensing units includes a compressor, a condenser, an expansion valve and a liquid separator connected in sequence device. The refrigerant inlet of the compressor in each group of compression and condensing units is respectively connected to the refrigerant outlet of the evaporator 1, and the refrigerant outlet of the liquid separator is respectively connected to the refrigerant inlet of the evaporator 1;

[0023] The evaporator 1 includes interconnected serpentine tube bundles 11 and synchronous superheated gas collector 12, the inlet of the serpentine tube bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com