Constant-depth-tooth bevel gear fault diagnosis method based on modified cepstrum

A technology of fault diagnosis and equal-height teeth, which is applied in the direction of machine gear/transmission mechanism testing, etc., and can solve problems such as difficult diagnosis work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be clearer through the following description combined with the accompanying drawings, and the accompanying drawings are used to explain the methods and embodiments of the present invention.

[0038] The flow chart of the contour bevel gear fault diagnosis method based on the improved cepstrum method of the present invention is as follows figure 1 Shown, the specific implementation steps of the present invention are as follows:

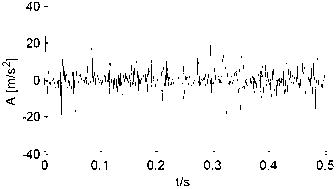

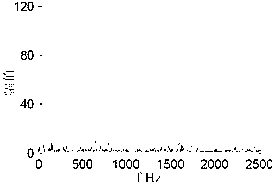

[0039] The first step: use the acceleration sensor to measure the contour bevel gearbox, and collect the gear acceleration vibration signal as the signal to be analyzed;

[0040] 1) Layout and related parameters of the signal acquisition system

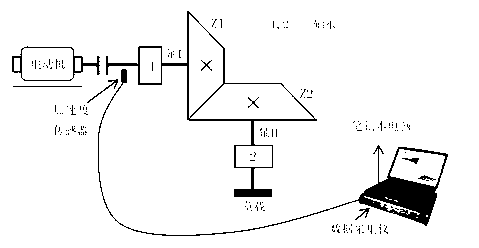

[0041] figure 2 It is a schematic layout diagram of the signal acquisition system, which is composed of a gear test bench, a data acquisition instrument and a notebook computer. Such as figure 2 As shown in , the experimental bench system mainly includes three parts, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com