Hot rolling method for silicon-ontaining steel slab

A billet and reheating technology, applied in the heating field of silicon-containing steel billets, can solve the problems of reduced surface quality of steel plates, impaired manufacturability, reduced magnetic properties, etc., and achieves the effect of reducing production failures, reducing surface defects and excellent surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

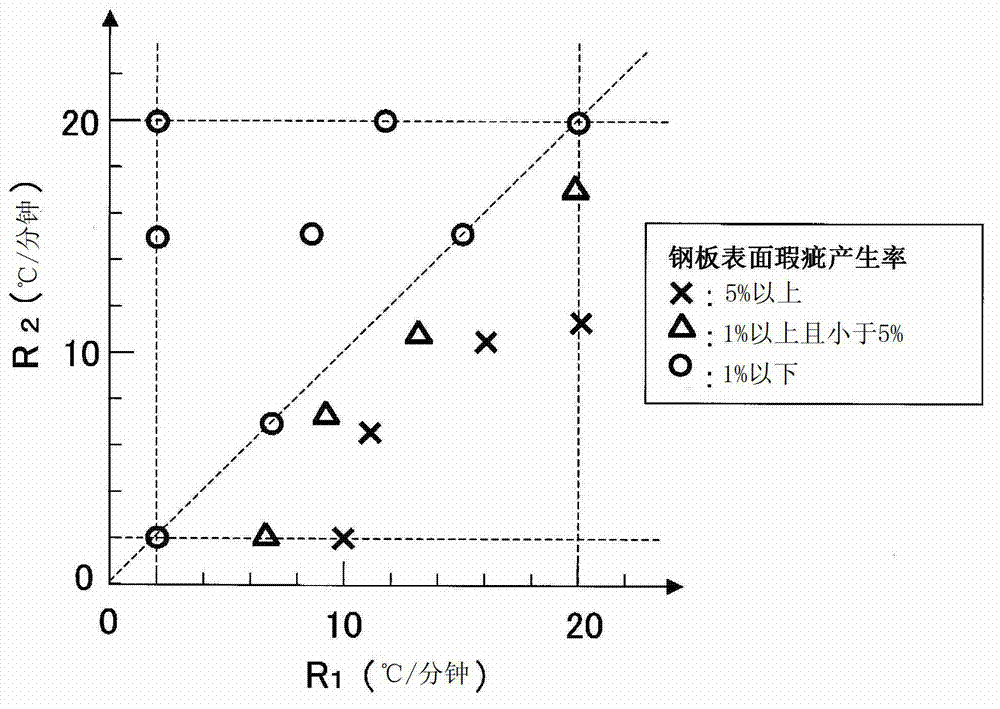

Embodiment 1

[0067] For the content of C: 0.003% by mass, Si: 3.8% by mass, Mn: 0.05% by mass, sol.Al: 0.0040% by mass, N: 0.0030% by mass, S: 0.0015% by mass, and Se: 0.0015% by mass, the remainder contains Fe and For steel billets with unavoidable impurities, the heating rate from the billet reheating to 750°C is set to R 1 、The heating rate from 750℃ to 1050℃ is set as R 2 , For these R 1 And R 2 Various changes were made, and it was reheated to 1100°C, and then hot-rolled to produce a hot-rolled sheet with a thickness of 2.5 mm. The rate of occurrence of surface defects in the hot-rolled sheet was studied. It should be noted that for the occurrence rate of the above-mentioned surface flaws, the full length of the surface and back of the hot-rolled coil is observed with a CCD camera, and the occurrence of surface flaws is judged in a unit of 10cm×10cm, and it will be judged as the surface The area ratio of the surface of the steel sheet with defects is regarded as the occurrence rate of s...

Embodiment 2

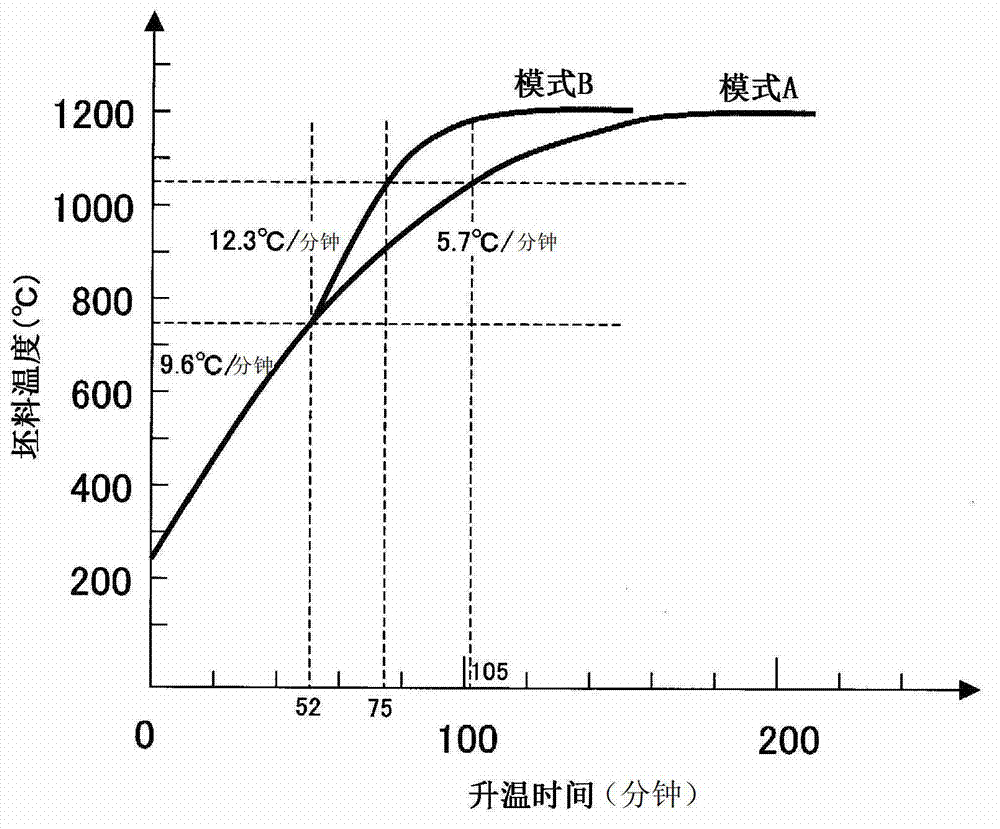

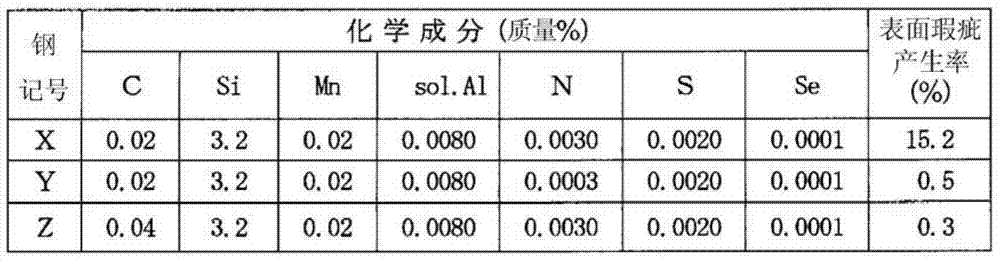

[0070] use figure 1 The two billet reheating modes shown in Table 2 reheat the steel billets with various compositions shown in Table 2 to 1200°C and perform hot rolling to produce a hot-rolled plate with a thickness of 2.0 mm, as in Example 1. Measure the rate of occurrence of surface flaws in the hot-rolled sheet, and record the results in Table 2. The two billet reheating modes are: for the heating rate below 750°C, both in mode A and mode B 9.6°C / min; the temperature increase rate from 750°C to 1050°C is 5.7°C / min in mode A and 12.3°C / min in mode B.

[0071] According to Table 2, for steel billets of Nos. 22 to 25 outside the composition range of the present invention that are less likely to cause surface defects, regardless of the heating mode, the occurrence rate of surface defects shows a low value. In contrast, for steel billets (Nos. 1 to 21) having the composition of the present invention that are prone to surface defects, the occurrence rate of surface defects is high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com