Puffing and sinking compound feed for takifugu obscures larvae

A technology of fugu obscurus and compound feed, which is applied in animal feed, animal feed, application, etc., can solve the problems that restrict the sustainable development of puffer fish farming industry, the consequences of poor growth speed, and increase the cost of breeding, so as to improve the pufferfish breeding industry. Effects on fish growth and quality, simplification of feeding operation and management, and reduction of breeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

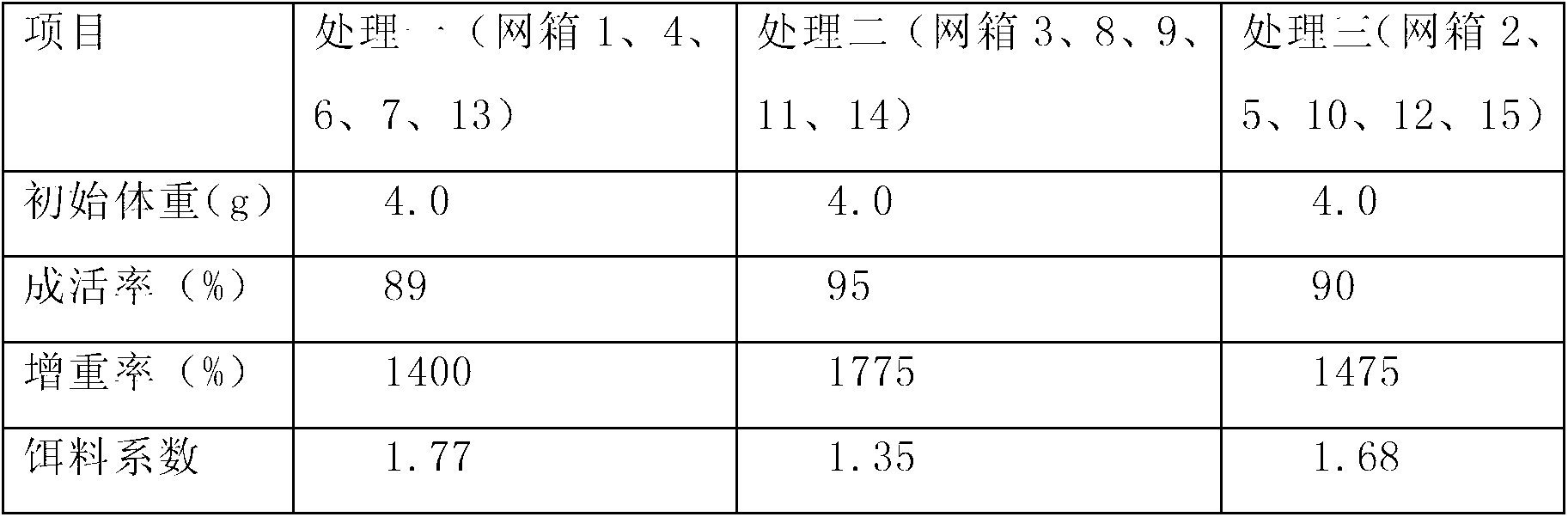

Embodiment 1

[0072] The puffed and sinking compound feed for puffer puffer larvae juveniles is added according to mass percentage: fish meal 40, soybean meal 16, cotton meal 10, flour 9.9, calcium dihydrogen phosphate 1.5, brewer's yeast 4, fermented soybean meal 8, fish oil 3, Puffed blood meal 3, squid paste 2, soybean lecithin oil 1, vitamin mixture 0.5, mineral mixture 1, liver and gallbladder protection agent 0.1, the above raw materials are ultrafinely pulverized and mixed, and then produced by Wenger puffing line.

Embodiment 2

[0074] The puffed and sinking compound feed for puffer puffer larvae juveniles was added according to mass percentage: fish meal 46, soybean meal 10, cotton meal 8, flour 7.9, calcium dihydrogen phosphate 2, brewer's yeast 5, fermented soybean meal 10, fish oil 3.5, Puffed blood powder 2, squid paste 3, soybean lecithin oil 1, vitamin mixture 0.5, mineral mixture 1, liver and gallbladder protection agent 0.1, the above raw materials are ultrafinely pulverized and mixed, and then produced by Wenger puffing line.

Embodiment 3

[0076] The puffed and sinking compound feed for puffer puffer juveniles, respectively added raw materials according to mass percentage: fish meal 50, soybean meal 8, cotton meal 7, flour 13.4, calcium dihydrogen phosphate 1.5, brewer's yeast 3, fermented soybean meal 8, fish oil 2, Puffed blood powder 2.5, squid paste 2, soybean lecithin oil 1, vitamin mixture 0.5, mineral mixture 1, liver and gallbladder protection agent 0.1, the above raw materials are ultrafinely pulverized and mixed, and then produced by Wenger puffing line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com