Spherical thermosetting fluorescent pigment production system

A technology for fluorescent pigments and production systems, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of low crosslinking density, color bleeding, uneven heating, long time, etc., to improve resin crosslinking density and anti-bleeding. Excellent performance, the effect of eliminating dead ends of shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

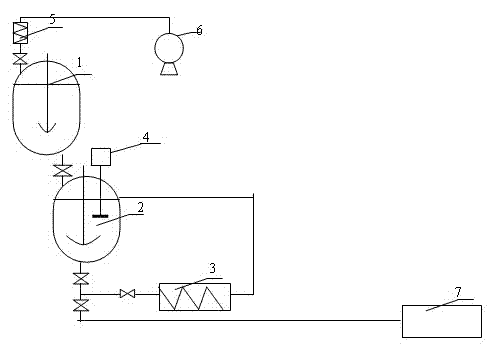

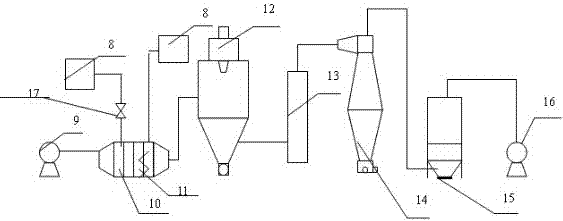

[0015] Spherical thermosetting fluorescent pigment production system, the system includes a production reaction assembly and a drying assembly, the drying assembly is arranged behind the production reaction assembly, and the production reaction assembly includes a series reaction kettle 1 and a shear kettle 2, and the reaction The top of the kettle 1 is connected with a condenser 5 and a vacuum pump 6, the top of the shear kettle 2 is connected with a high-shear emulsifier 4, and the bottom of the shear kettle 2 is connected with a high-pressure homogenizer 3 and a spray dryer 7. The drying assembly includes a temperature controller 8, a blower 9, a heater group, a drying unit, a dust removal unit and an induced draft fan 16, and the described heater group includes an oil heater 10 and an electric heater 11, and the described drying unit includes a centrifugal spray Dryer 12, cyclone drying pipe 13, the dust removal unit includes a cyclone dust collector 14 and a bag dust colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com