Piezoelectric array ultrasonic transducer

An ultrasonic transducer, piezoelectric technology, applied in the direction of fluid using vibration, etc., can solve the problems of difficult packaging, poor stability and comprehensive performance, low operating frequency, etc., to achieve convenient packaging, improved sensitivity, and good integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

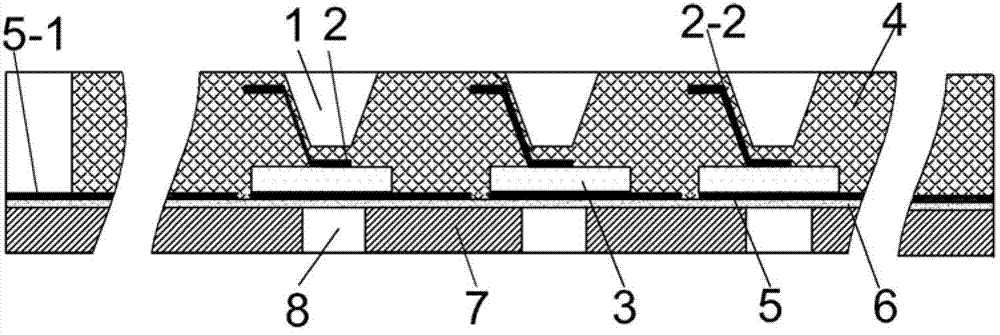

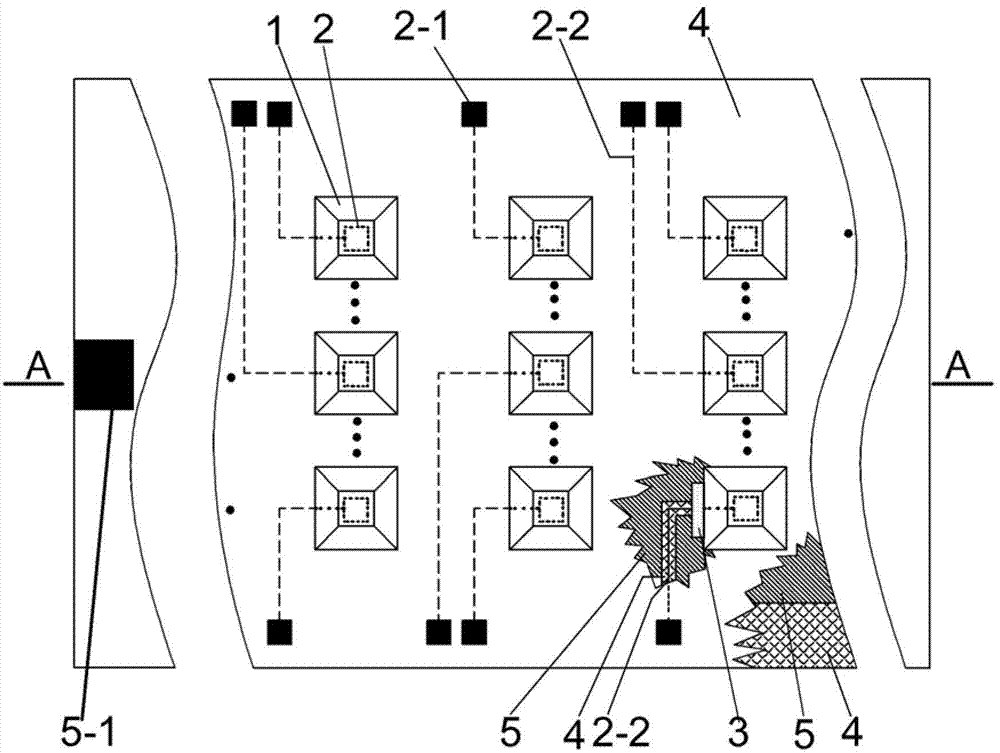

[0012] In this implementation mode, an ultrasonic transducer using AlN (aluminum nitride) piezoelectric film and the number of elements in the array is 2×2, two of which are 1.25MHz elements and two of which are 2.9MHz elements: the base 7. Single crystal silicon of (length×width×thickness) 10×10×0.25mm is used, and each vibration cavity 8 is set on it (length×width×thickness) 0.18×0.18×0.25mm, and the vibration cavity 8 on it is (length×width×thickness) 0.18×0.18×0.25mm (2.9MHz array element) and 0.21×0.21×0.25mm (1.25MHz array element); the support layer 6 is made of silicon dioxide, its thickness is 350nm, and the length and width are equal The same as the substrate 7; the lower electrode 5 has the same horizontal length as the substrate, a longitudinal width of 7mm, and a thickness of 280nm, made of platinum-titanium alloy, magnetron sputtered on the silicon dioxide support layer 6, and the line corresponding to the lead-out line of the upper electrode The width of the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com