Grinding method for solar battery germanium substrate slices

A technology of solar cells and grinding methods, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of uneven force on Template, difficult to control, uneven wafer drop, etc., and achieve easy control of processing volume and grinding accuracy. High, uniform grinding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

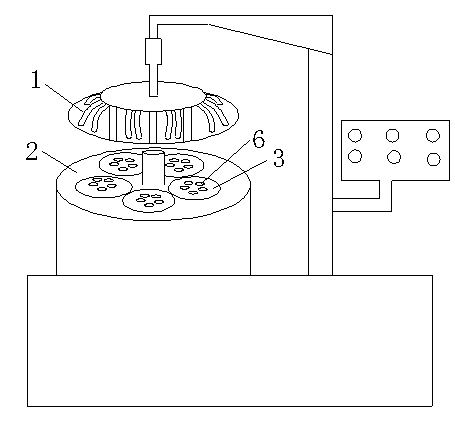

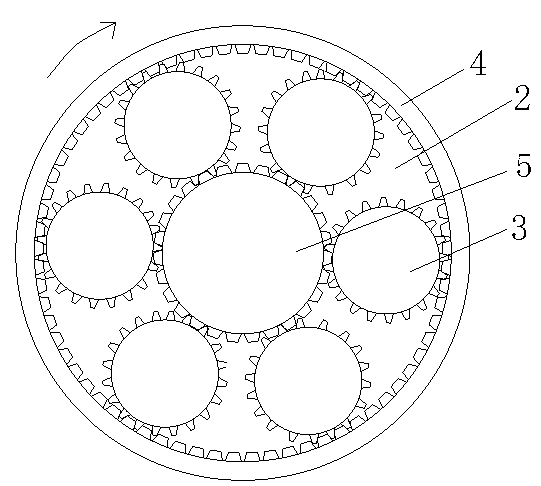

[0024] Embodiment 1: incoming material germanium sheet is 4 inches, and thickness is 285 μ m, double-sided grinder model X61 850B-1 type (Lanzhou Ruide), as figure 1 , figure 2 As shown, a star wheel 3 with a specification of 13DPb×0.25×φ100.5mm is used, and the grinding method includes the following steps:

[0025] Firstly, debug the grinding machine, check the runout of the upper end surface of the lower grinding disc 2, so that the runout of the lower grinding disc 2 is not greater than 0.06mm, and at the same time, ensure that the pressure value of each grinding stage of the grinder shall not exceed the system of the upper grinding disc 1 weight, otherwise the grinder will not function properly.

[0026] Secondly, the preparation of the grinding liquid: mix 2 parts of aluminum oxide powder and 7 parts of pure water according to the weight ratio, stir for 10 minutes, add 0.6 parts of detergent, and stir for another 10 minutes to mix the three evenly, avoiding Agglomerati...

Embodiment 2

[0037] The incoming germanium sheet is 6 inches, the thickness is 320μm, the double-sided grinding machine model X61 850B-1 (Lanzhou Ruide), such as figure 1 , figure 2 As shown, a planetary wheel 3 with a specification of 13DPb×0.28×φ151.5mm is used, and the grinding method includes the following steps:

[0038] First of all, carry out the debugging of the grinding machine, and detect the runout of the upper end face of the lower grinding disc 2, so that the runout of the lower grinding disc 2 is not greater than 0.06mm, and at the same time, ensure that the pressure value of the grinding machine in each grinding stage does not exceed the system of the upper grinding disc 1 weight, otherwise the grinder will not function properly.

[0039] Secondly, the preparation of the grinding liquid: mix 2.5 parts of aluminum oxide powder and 7 parts of pure water according to the weight ratio, after stirring for 10 minutes, add 0.8 parts of detergent, and stir for 10 minutes to mix th...

Embodiment 3

[0050] The incoming germanium sheet is 8 inches, the thickness is 400μm, the double-sided grinding machine model X61 850B-1 (Lanzhou Ruide), such as figure 1 , figure 2 As shown, a planetary wheel 3 with a specification of 13DPb×0.35×φ202.5mm is used, and the grinding method includes the following steps:

[0051] First of all, carry out the debugging of the grinding machine, and detect the runout of the upper end face of the lower grinding disc 2, so that the runout of the lower grinding disc 2 is not greater than 0.06mm, and at the same time, ensure that the pressure value of the grinding machine in each grinding stage does not exceed the system of the upper grinding disc 1 weight, otherwise the grinder will not function properly.

[0052] Secondly, the preparation of the grinding liquid: mix 3 parts of aluminum oxide powder and 7 parts of pure water according to the weight ratio, after stirring for 10 minutes, add 1 part of detergent, and stir for 10 minutes to make the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com