System and method for controlling automatic drug racking and placing device

A control system and device placement technology, which is applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of high application cost and low efficiency of manual drug shelves and visits, and achieve low cost, simple structure and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

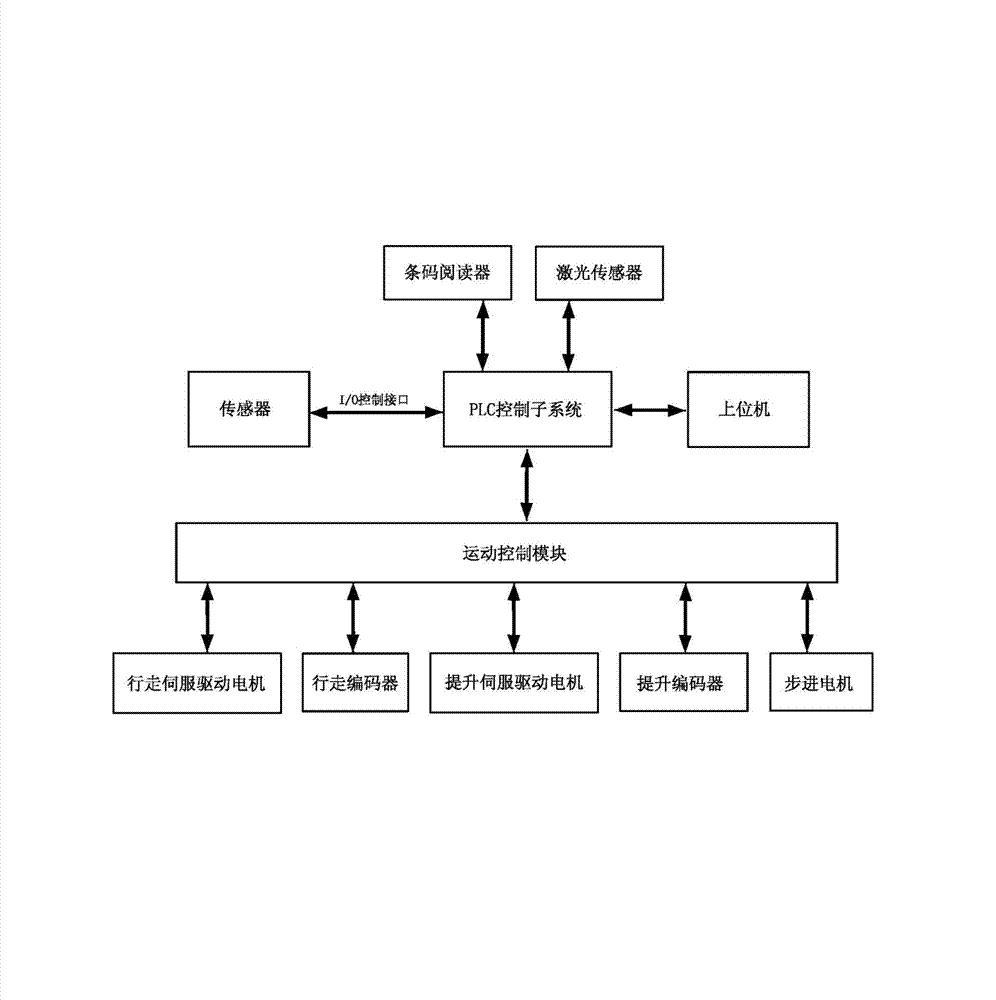

[0023] refer to figure 1 As shown, a control system for an automatic drug shelf placement device is characterized in that the control system includes a PLC control subsystem, a barcode reader and a motion control module, and the barcode reader is connected to the PLC control subsystem. The PLC control subsystem is connected to the upper computer, and the PLC control subsystem is also connected to the servo drive motor and the stepper motor through the motion control module, and the motion control module is also connected to the motion encoder, wherein:

[0024] The function of the above barcode reader is to scan the barcode information of the drug, and transmit the barcode information to the host computer through the PLC control subsystem;

[0025] The function of the above-mentioned upper computer is to read the actual size of the drug and the coordinate information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com