Solid wood acoustical board and manufacturing method thereof

A technology of sound-absorbing panels and solid wood, applied in the field of sound-absorbing materials, can solve the problems of unfavorable environmental protection, limited use, poor sound-absorbing effect, adhesives, etc., and achieve the effect of increasing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

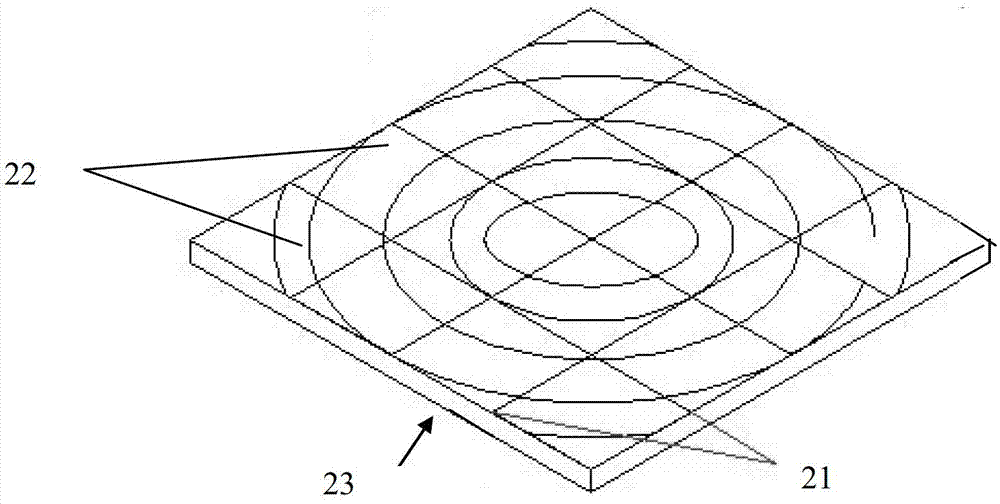

Image

Examples

Embodiment 1

[0033] Example 1: Production of solid wood sound-absorbing panels

[0034] Set the density to 0.6g / cm 3 The following fast-growing materials, such as poplar, are cut into rectangular strips, bonded radially, and then cut from the end to form multi-section wooden squares; the wooden squares are bonded to form solid wood sound-absorbing panels. The joints are glued with a room temperature curing adhesive, such as white latex.

Embodiment 2

[0035] Embodiment 2: the making of a kind of poplar sound-absorbing board

[0036] The poplar produced in Hebei (origin) is selected, and its air-dry density is 0.35g / cm 3 , with a moisture content of 10%, as the solid wood material of the sound-absorbing panel, the specific production steps of the poplar sound-absorbing panel are as follows:

[0037] 1) After the poplar wood is cut into cuboid blocks, they are bonded radially, and then cut along the cross-section from the end to form multi-section poplar wood blocks after cutting;

[0038] 2) Place the squares of poplar trees along their cross-sections towards the outer surface of the poplar sound-absorbing board, and glue the fast-growing wood squares with white latex to obtain the solid wood sound-absorbing board. The outer surface of the sound-absorbing panel obtained in this way is composed of the cross-section of wood, and because the cross-section of wood has a porous structure, the sound-absorbing performance of the s...

Embodiment 3

[0040] Example 3: Production of a Chinese fir sound-absorbing panel

[0041] Choose fir from Sichuan (place of origin), with an air-dry density of 0.38g / cm 3 , with a moisture content of 10%. As the solid wood material of the sound-absorbing panel, the same manufacturing steps as in Example 2 were used, except that isocyanate was used as the adhesive to make a Chinese fir sound-absorbing panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com