Fabrication method of stress-matched bi-material micro-cantilever beam

A micro-cantilever beam and stress matching technology, applied in the manufacture of microstructure devices, metal material coating technology, microstructure technology and other directions, can solve the continuous adjustment of Al film stress, can not achieve complete Al film stress and stress matching, thin film preparation process It is impossible to take into account the problems of complete stress matching and corrosion resistance, so as to achieve the effect of enhanced corrosion ability, complete stress matching and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

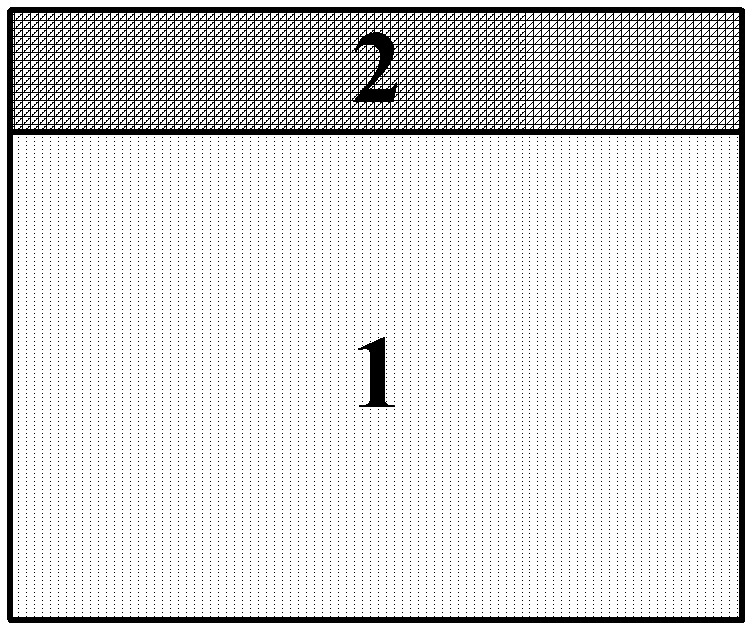

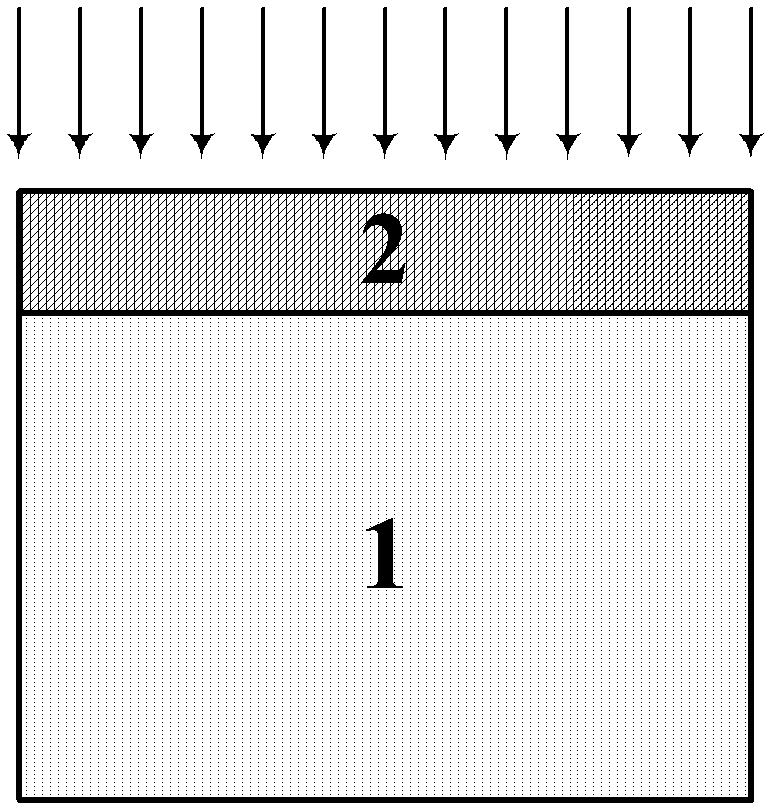

[0032] The features and technical effects of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and in combination with schematic embodiments, and a method for manufacturing a dual-material micro-cantilever beam that takes into account complete stress matching and corrosion resistance is disclosed. It should be pointed out that similar reference numerals represent similar structures, and the terms "first", "second", "upper", "lower" and the like used in this application can be used to modify various device structures or manufacturing processes . These modifications do not imply spatial, sequential or hierarchical relationships of the modified device structures or fabrication processes unless specifically stated.

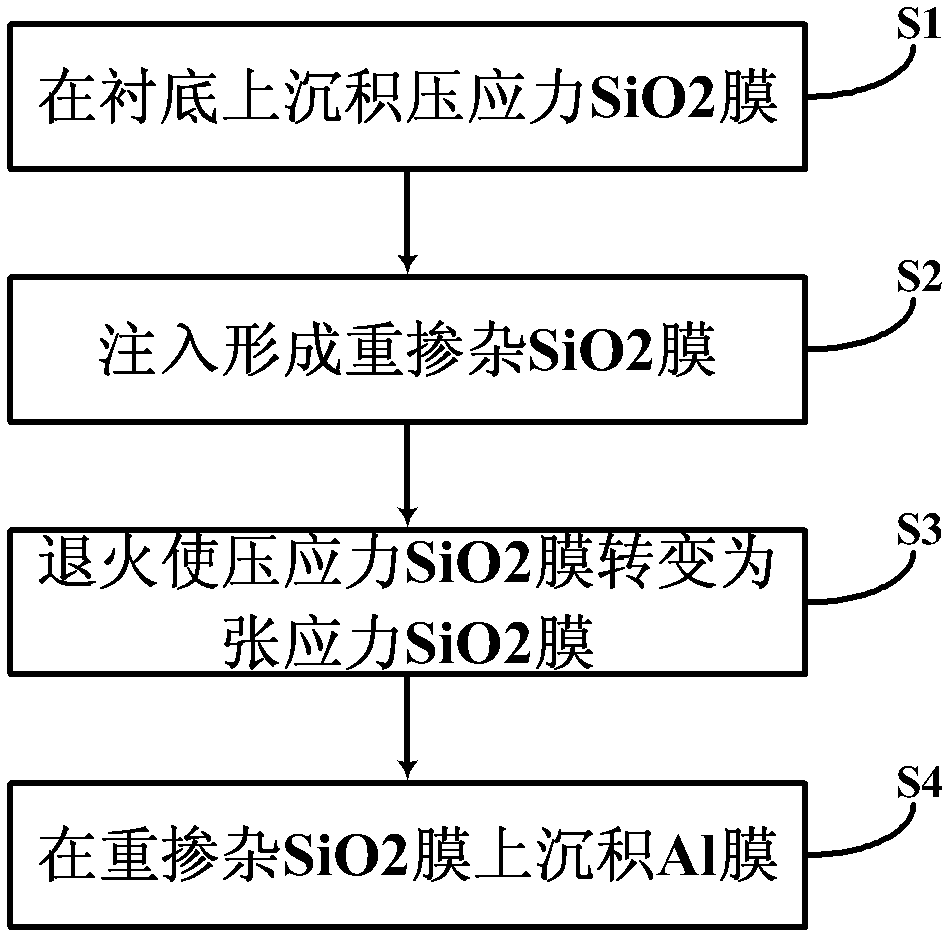

[0033] The invention provides a method for manufacturing a stress-matched dual-material micro-cantilever beam, and the process of an embodiment thereof refers to figure 1 , the specific proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com