A realization method of micro-LED chip interconnection

A technology of LED chips and implementation methods, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult packaging process, low optical power of micron-level LEDs, poor heat dissipation, etc., to reduce process difficulty, good heat dissipation performance, Improve the effect of insulating layer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] After the sapphire substrate LED epitaxial wafer is pickled, organic cleaned, and deionized water rinsed until the surface is free of contamination and oxide layer and dried, a layer of ITO is evaporated as a current spreading layer;

[0021] Coater coating photoresist, through exposure and development, to form a number of mesa array photolithographic patterns, the pattern size is 5-200 microns;

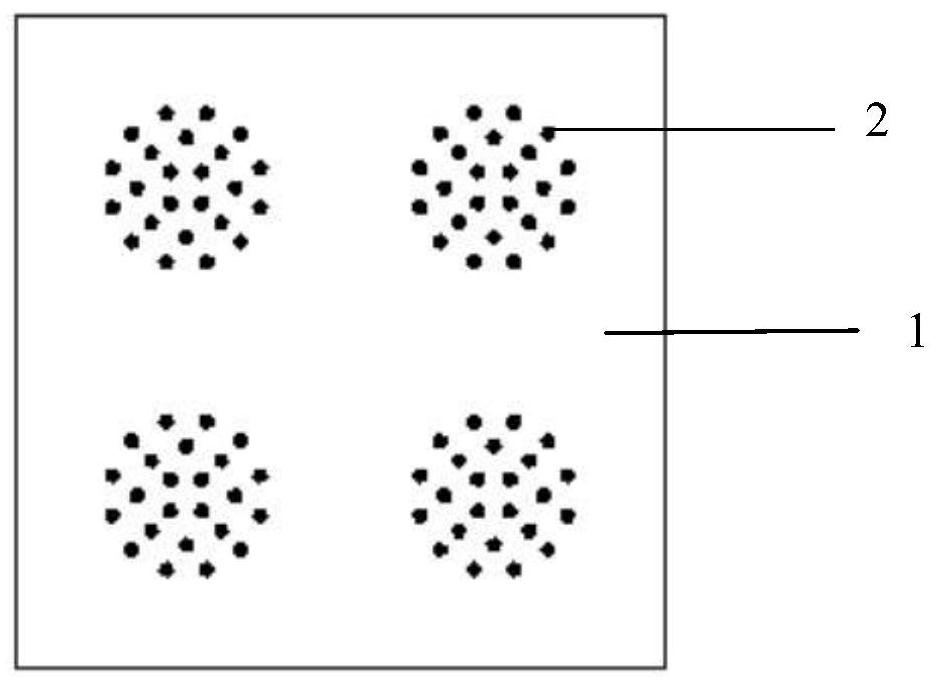

[0022] Use ICP dry etching to etch away the area not protected by the photoresist until the structural layer forms a mesa, and the mesa size is 5-200 microns, such as figure 1 shown;

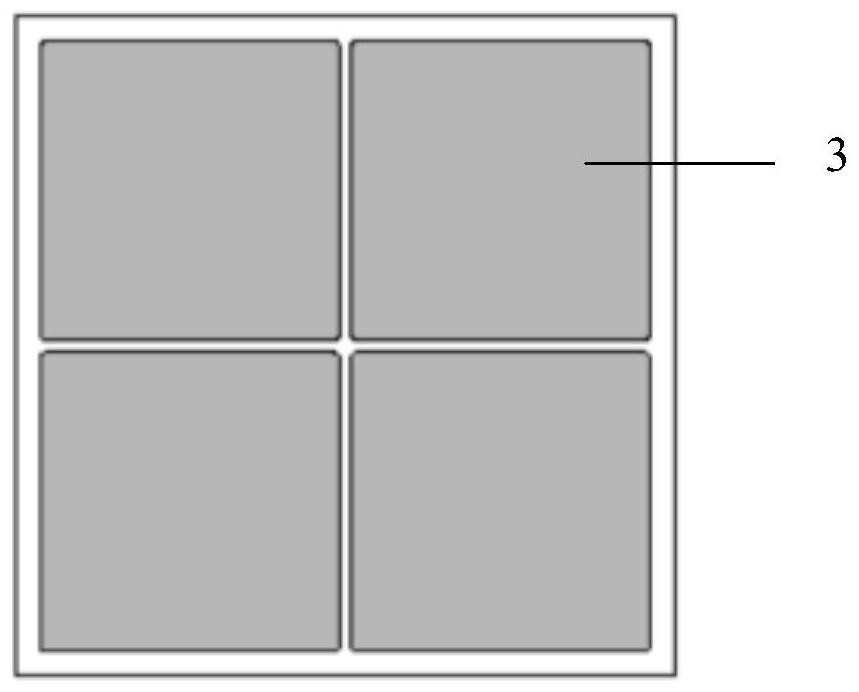

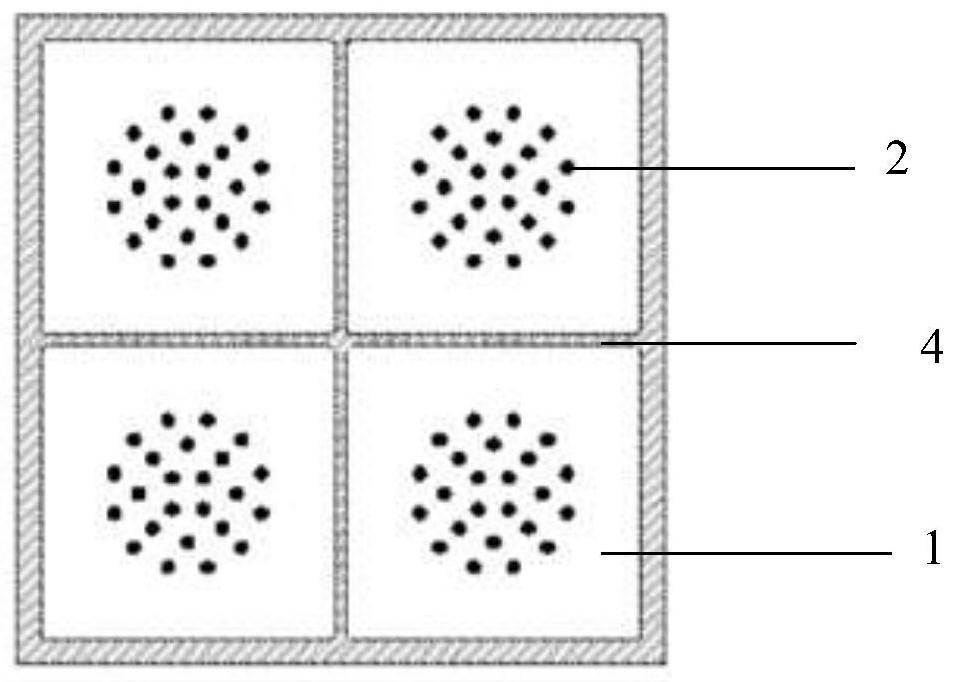

[0023] The coater coats the photoresist, and through exposure and development, the isolation area between the arrays is formed, such as figure 2 Shown with 4 LED array units isolated from each other;

[0024] Plasma deeply etches the area not protected by the photoresist to the upper surface of the structural layer to form an array isolation region; the number and size of the isolation regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com