Method for synthesizing nickel carbonyl under medium pressure in rotating kettle

A technology of nickel carbonyl and copper-nickel alloy, applied to nickel carbonyl and other directions, can solve the problems of high operating pressure, low yield and high production cost, and achieve the effects of low pressure requirement, high yield and shortened reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

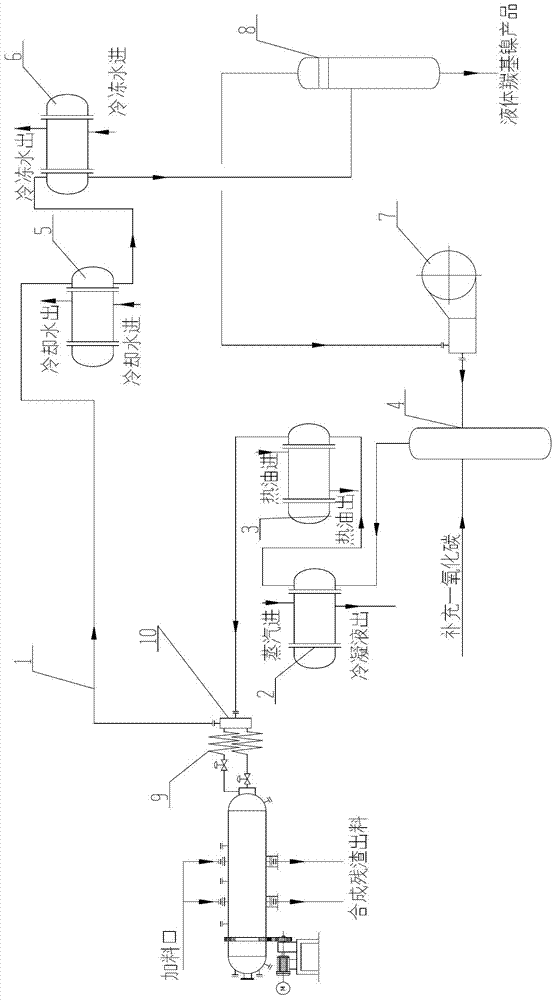

Image

Examples

Embodiment 1

[0021] A method for synthesizing nickel carbonyl under pressure in a rotating kettle, comprising the following preparation process:

[0022] (1) Preparation of water-quenched copper-nickel alloy particles: Add copper and sulfur with a mass ratio of 4:1 to the copper-nickel alloy, heat and melt, let the melt flow into a water quenching pool at a temperature of 50°C, and spray water to Crushing the melt into active water-quenched copper-nickel alloy particles with a particle size of 10 nm;

[0023] (2) Carboxylation reaction: Water-quenched copper-nickel alloy particles are added to the rotating kettle. The operating pressure in the rotating kettle is 8.5Mpa and the operating temperature is 180°C. The copper-nickel water-quenching alloy is added to the rotating kettle. Nitrogen at a pressure of MPa (G) is sent into the kettle for air replacement, and then check whether there is any leakage. After the inspection, the nitrogen is emptied. After no leakage, inject 8.0MPa (G) carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com