Water purifying device

A water purification device, cyclone mixing technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex equipment structure, short backwash cycle, blockage, etc., to improve sedimentation efficiency, prolong popular time, extend The effect of the backwash cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

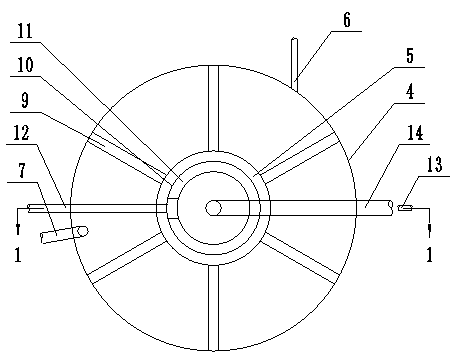

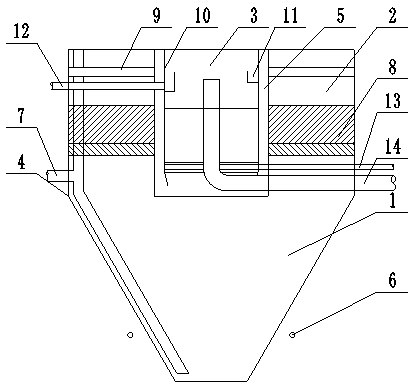

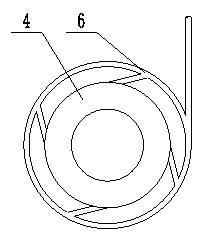

[0026] The water purification treatment device, including the swirl mixing reaction zone 1, the high-efficiency inclined plate sedimentation zone 2 and the shallow filter zone 3, is a continuous concentric circular reactor. The upper part of the equipment body 4 is a cylindrical shell, and the lower part of the equipment body 4 It is a conical shell, and the middle part of the cylindrical shell is a circular filter pool 5 concentric with the cylindrical shell. The area surrounded by the conical shell is a swirl mixing reaction zone 1. The cylindrical shell and the filter pool The part between 5 is the high-efficiency inclined plate sedimentation zone 2, and the inside of the filter tank 5 is a shallow filter zone 3; the lower part of the conical shell is provided with an annular water distribution pipe 6 surrounding the conical shell, and the distribution The water pipe 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com