Industrial continuous environmentally-friendly and energy-saving scrap tire thermal cracking equipment

A waste tire and energy-saving technology, which is applied in the field of industrial continuous environmental protection and energy-saving waste tire thermal cracking equipment, can solve the problems of high production cost, short service life and poor safety performance of thermal cracking equipment, and achieve good social and economic benefits. , long service life, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

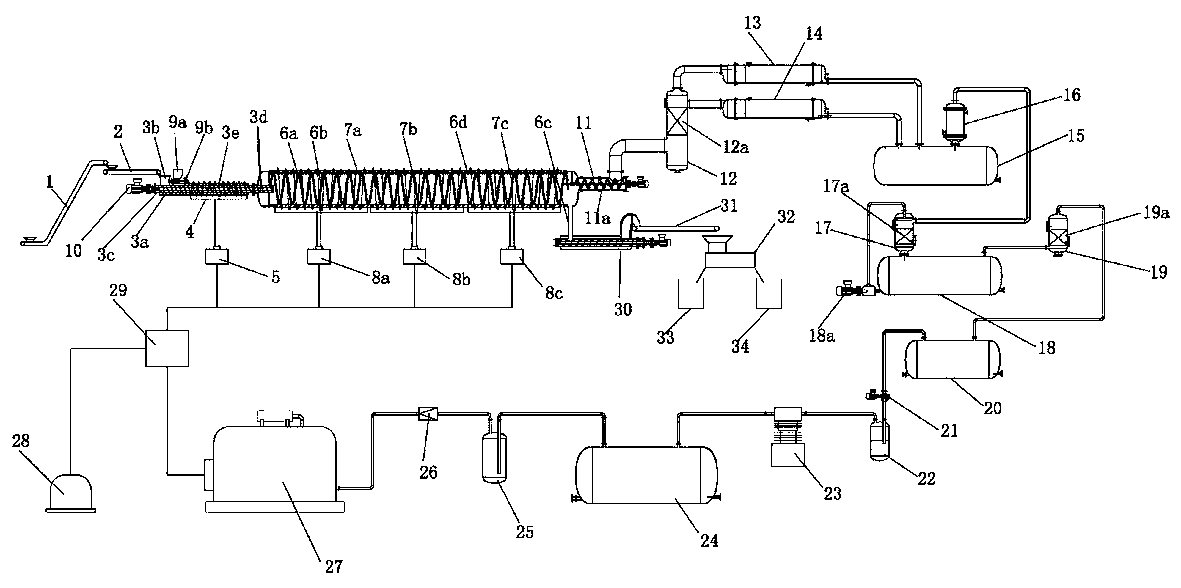

[0007] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0008] Depend on figure 1 Given, the present invention comprises conveyer, screw feeder, condenser, auger machine, magnetic separator, circulation pump and gas generator, and the first conveyer 1 is placed in the second for material weighing in an upward inclination. On one side of the conveyor 2, the discharge end of the first conveyor 1 for material lifting is placed above the feed port of the second conveyor 2, and the discharge end of the second conveyor 2 is placed at the inlet of the screw feeder. Above the feed port 3b, the discharge end of the screw feeder is connected to the feed end of the cracking kettle, and the discharge end of the cracking kettle is connected to the air inlet of the reaction tower 12 through the outlet tube 11, and the gas outlet of the reaction tower 12 is respectively connected to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com