Countercurrent high-pressure-injection emulsion breaker filling device

A high-pressure injection and filling device technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of affecting the demulsification effect, uneconomical, inapplicability, etc., and achieves improved demulsification effect, convenient operation and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

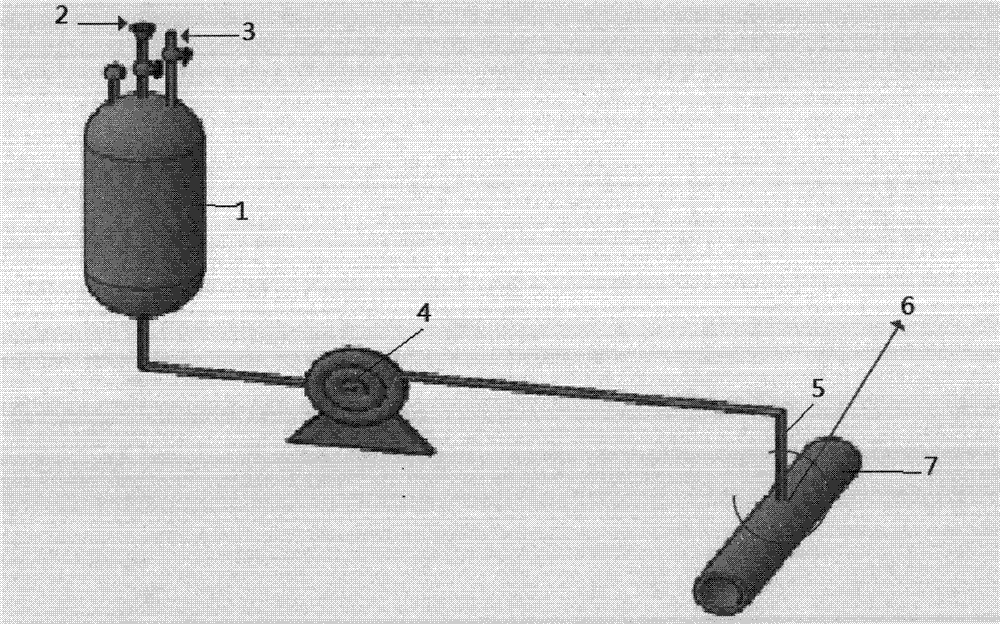

[0022] As can be seen from the figure, a countercurrent high-pressure injection demulsifier filling device, a storage tank (1), a feed port (2), an air outlet (3), a metering pump (4) and a filling pipe (5) and main pipe (7),

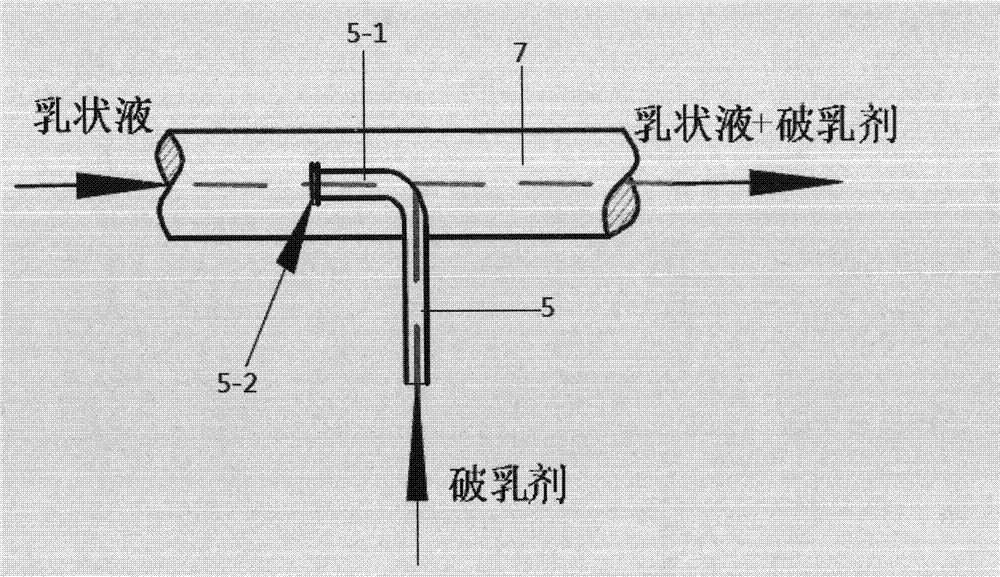

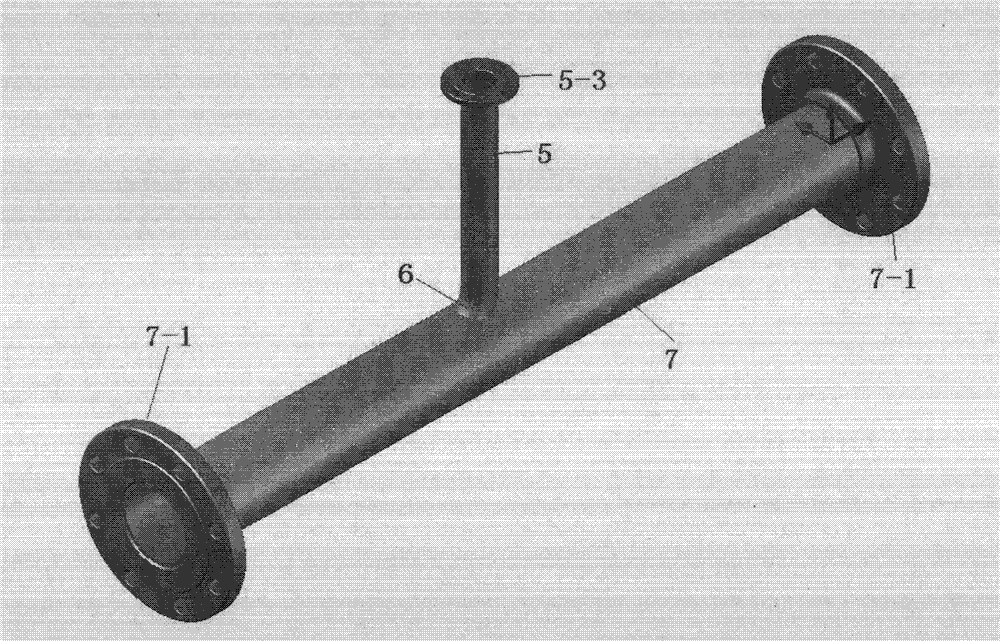

[0023] The feed opening (2) and the air outlet (3) are located on the top of the storage tank (1), the storage tank (1) is used to store the demulsifier, and the wall of the main pipeline (7) has a Injection hole (6), one end of the filling pipe (5) is connected to the bottom of the storage tank (1), and the other end passes through the filling hole (6) and enters the inside of the main pipeline (7), and the filling pipe (5) ) enters the inside of the main pipeline (7) to form a bent portion (5-1), the central axis of the bent portion (5-1) coincides with the central axis of the main pipeline (7), and the demulsifier is injected by The pipe (5) flows into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com