Three-stage water supply pipe double-impulse ultrasonic hydraulic balance adjusting system

A technology of hydraulic balance and adjustment system, applied in water supply installations, water supply installations, buildings, etc., can solve the problem of optimal control that is difficult to achieve high efficiency and low energy consumption, dynamic and real-time control of water supply pipe network terminals, and water supply pipelines. The problem of difficulty in adjusting the primary network and the secondary network is that the adjustment process is simple and intuitive, the energy saving potential is tapped, and the measurement cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

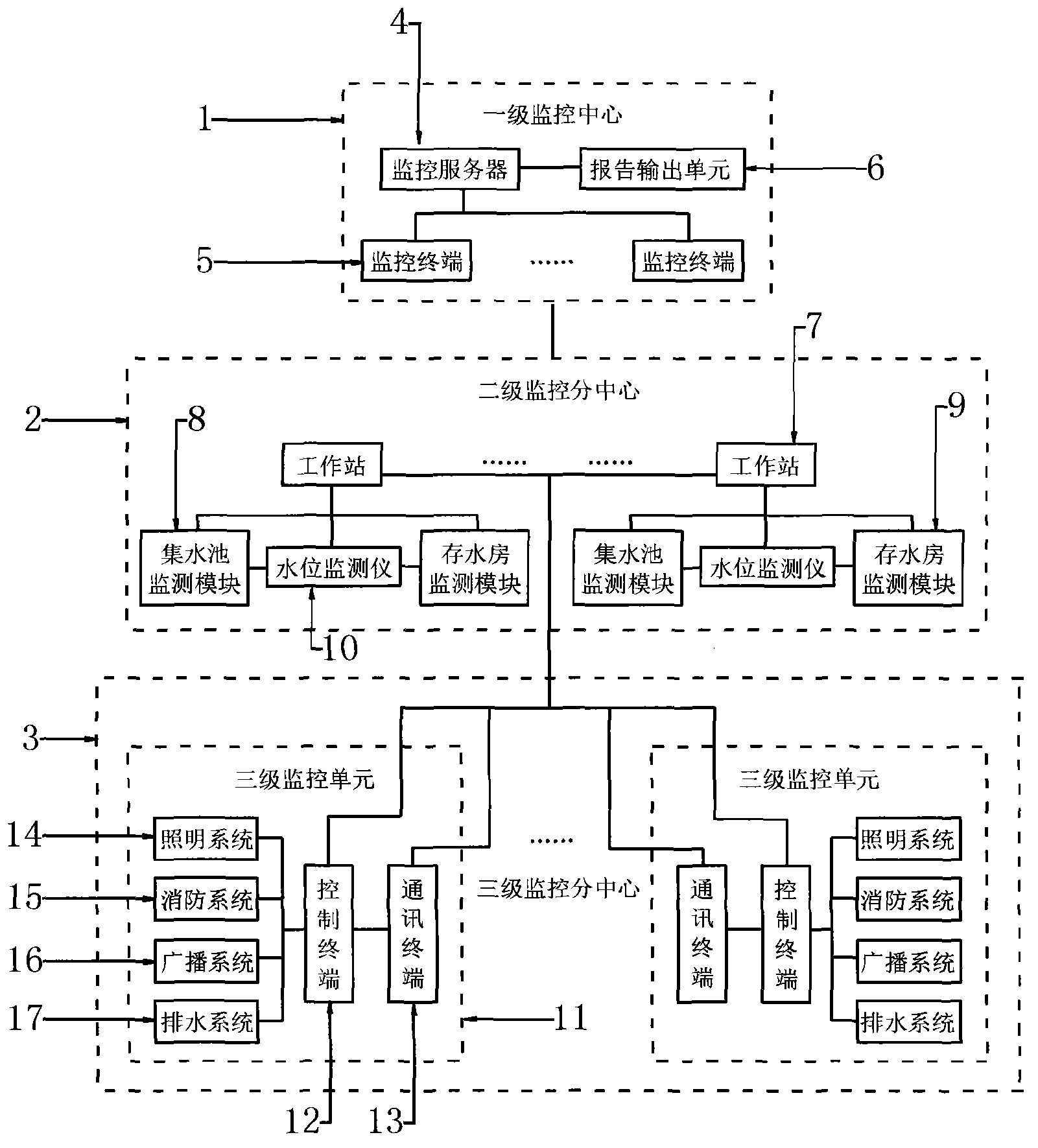

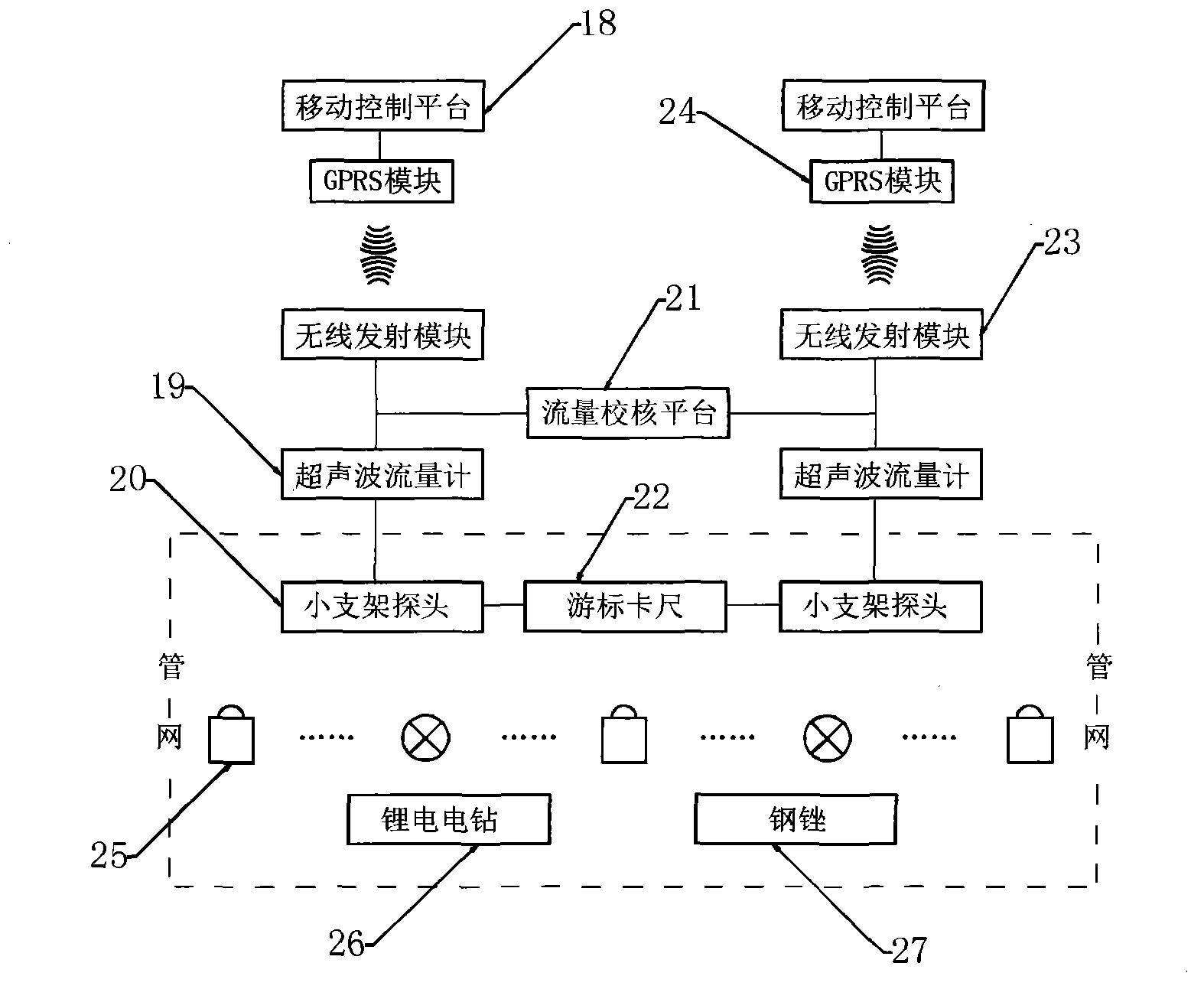

[0033] Such as figure 1 As shown, the present invention includes a three-level monitoring management system and a terminal maintenance system. The three-level monitoring management system includes a first-level monitoring center 1, a second-level monitoring sub-center 2 and a third-level monitoring sub-center 3. The terminal maintenance system includes Ultrasonic flow meter 19, wireless transmission module 23, mobile control platform 18, small bracket probe 20 and bottom control system, the three-level monitoring management system and terminal maintenance system are connected through wireless transmission module 23 as a signal path.

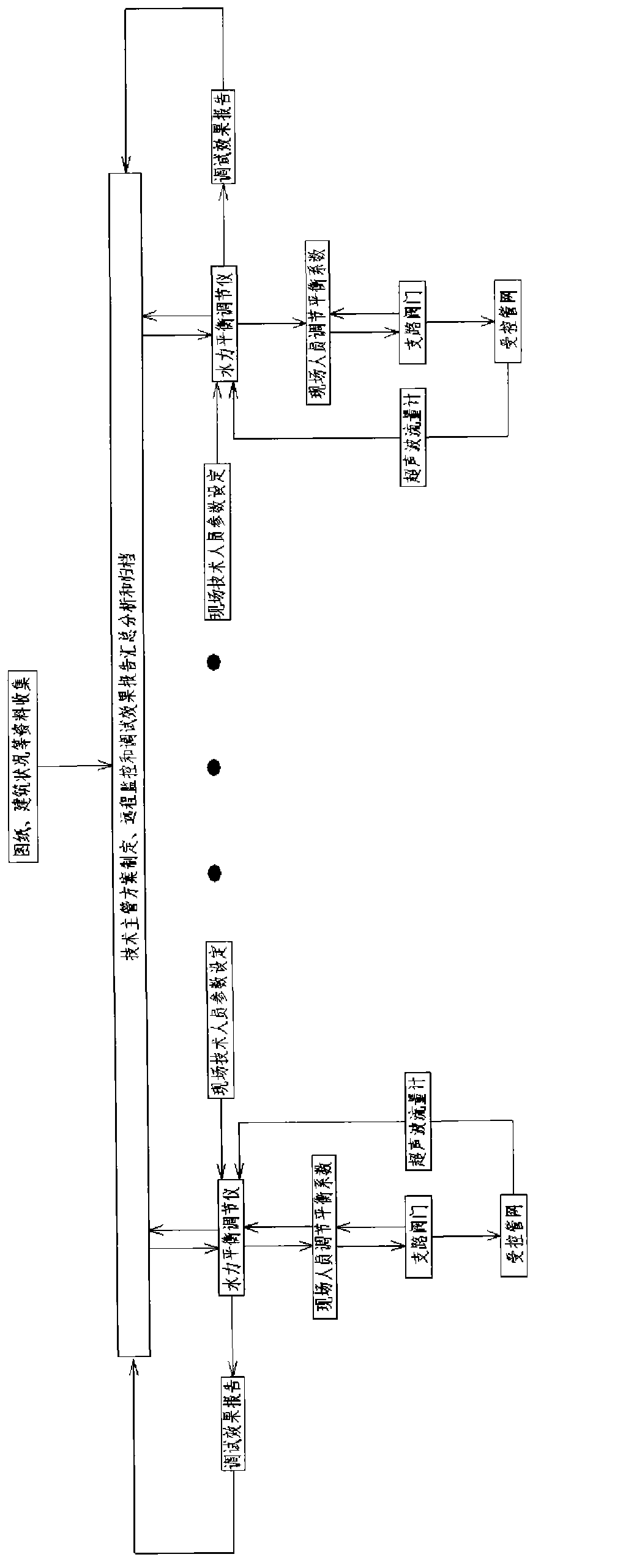

[0034] The pipe network control system adopts three-level control, with the dual-impulse ultrasonic water conservancy balance regulator as the core. The technical person in charge formulates a management control plan based on the buildi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com