The recovery method of microwave-assisted solvent extraction of heavy oil

An extraction method and microwave-assisted technology, which are applied in the fields of fluid extraction, earth-moving drilling, wellbore/well components, etc., can solve the problems of high resistance to solvent-dissolved oil, slow oil extraction, and low oil production, so as to improve oil production. Effects of velocity and recovery, reduced production costs, high flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

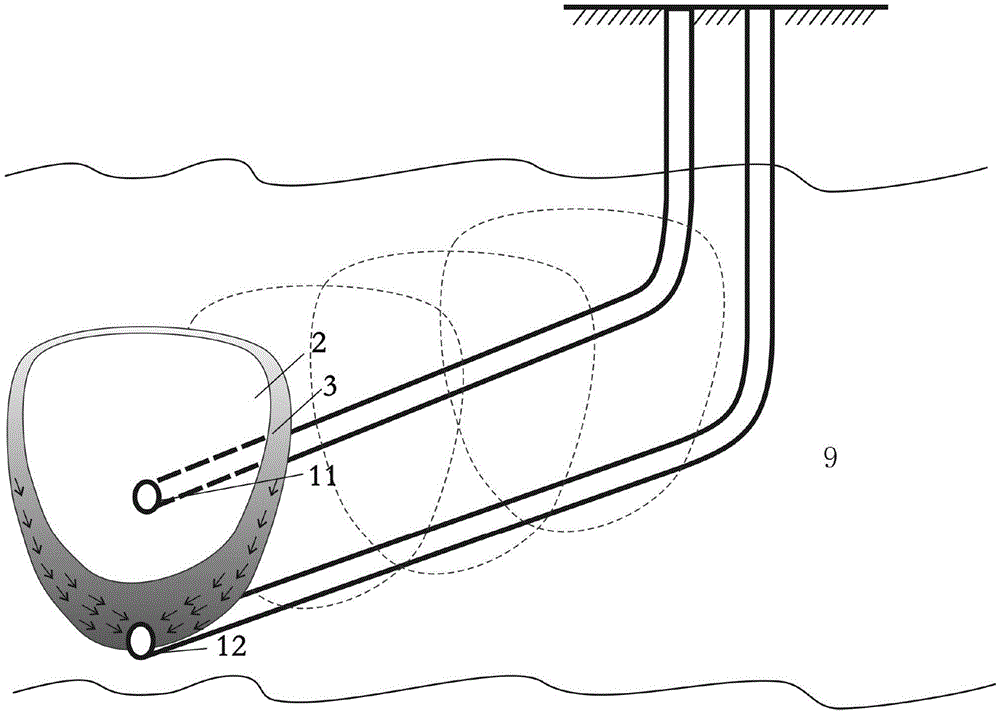

[0047] The production method of the present invention is explained by taking a certain heavy oil reservoir as an example, but it should be noted that the present invention is by no means limited to the heavy oil reservoir. The reservoir depth is 300m, the crude oil viscosity at the reservoir temperature is 100,000 centipoise, the original average formation pressure is 2.5MPa, and the effective average thickness of oil layer 9 is 15m.

[0048] A. Deploy horizontal injection-production well pattern:

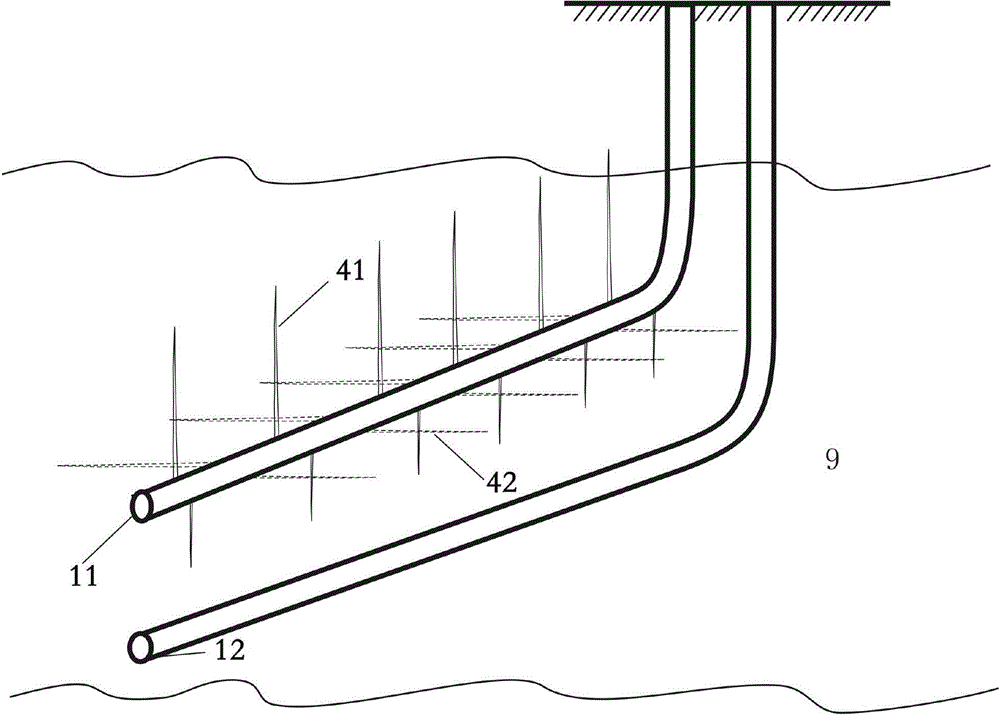

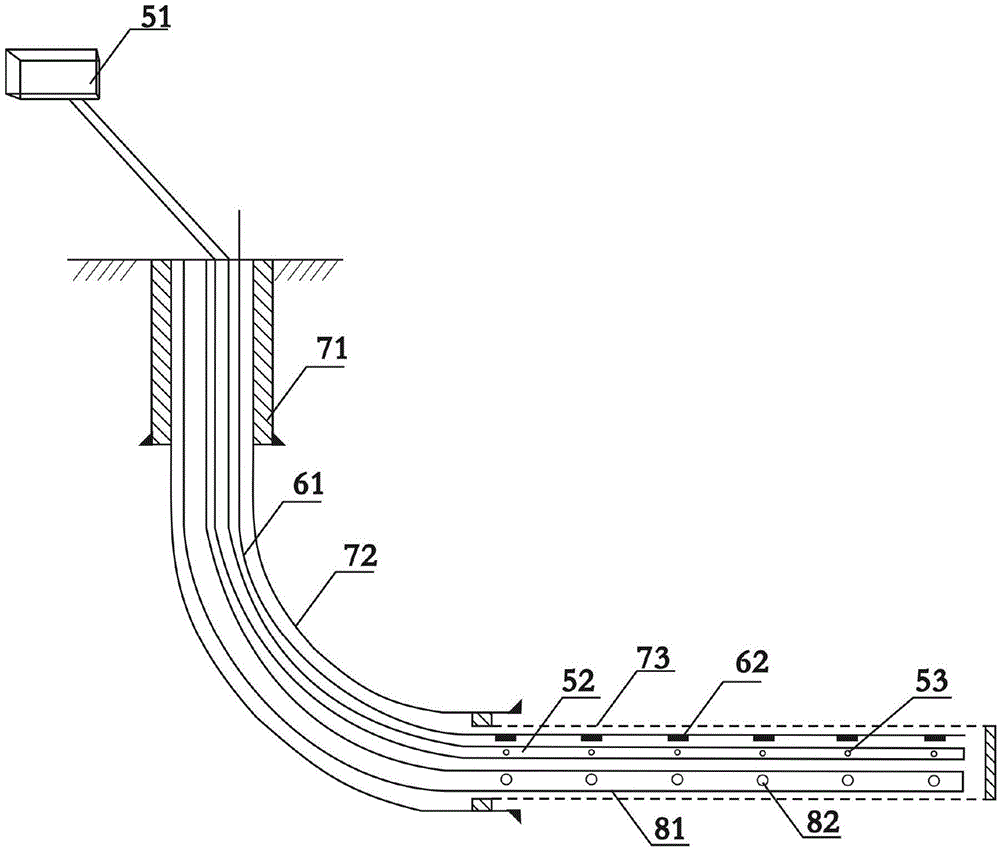

[0049] Such as figure 1 As shown, first, an upper horizontal well (solvent injection well) 11 and a lower horizontal well (production well) 12 are set in the main heavy oil layer 9 of the shallow heavy oil reservoir, and the upper horizontal well 11 and the lower horizontal well 12 are located in the same vertical Plane position;

[0050] During the drilling process, in order to ensure that the vertical distance between the horizontal section of the upper horizontal well 11 and t...

Embodiment 2

[0065] The reservoir depth is 400m, the crude oil viscosity at the reservoir temperature is 200,000 centipoise, the original average formation pressure is 3.5MPa, and the effective average thickness of oil layer 9 is 25m.

[0066] A. Deploy horizontal injection-production well pattern:

[0067] Such as figure 1 As shown, first, an upper horizontal well (solvent injection well) 11 and a lower horizontal well (production well) 12 are set in the main heavy oil layer 9 of the shallow heavy oil reservoir, and the upper horizontal well 11 and the lower horizontal well 12 are located in the same vertical Plane position;

[0068] During the drilling process, in order to ensure that the vertical distance between the horizontal section of the upper horizontal well 11 and the horizontal section of the lower horizontal well 12 is 5-6m, the well trajectory is precisely controlled by magnetic guidance;

[0069] Both the solvent injection well and the production well are completed by conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com