Coal measure strata tunnel milling digging and blasting combined construction method

A technology of milling and excavation in coal strata, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of high risk of coal seam gas tunnels, continuous local landslides, large blasting disturbance, etc., and achieve high operating environment and construction safety , Surrounding rock disturbance is small, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

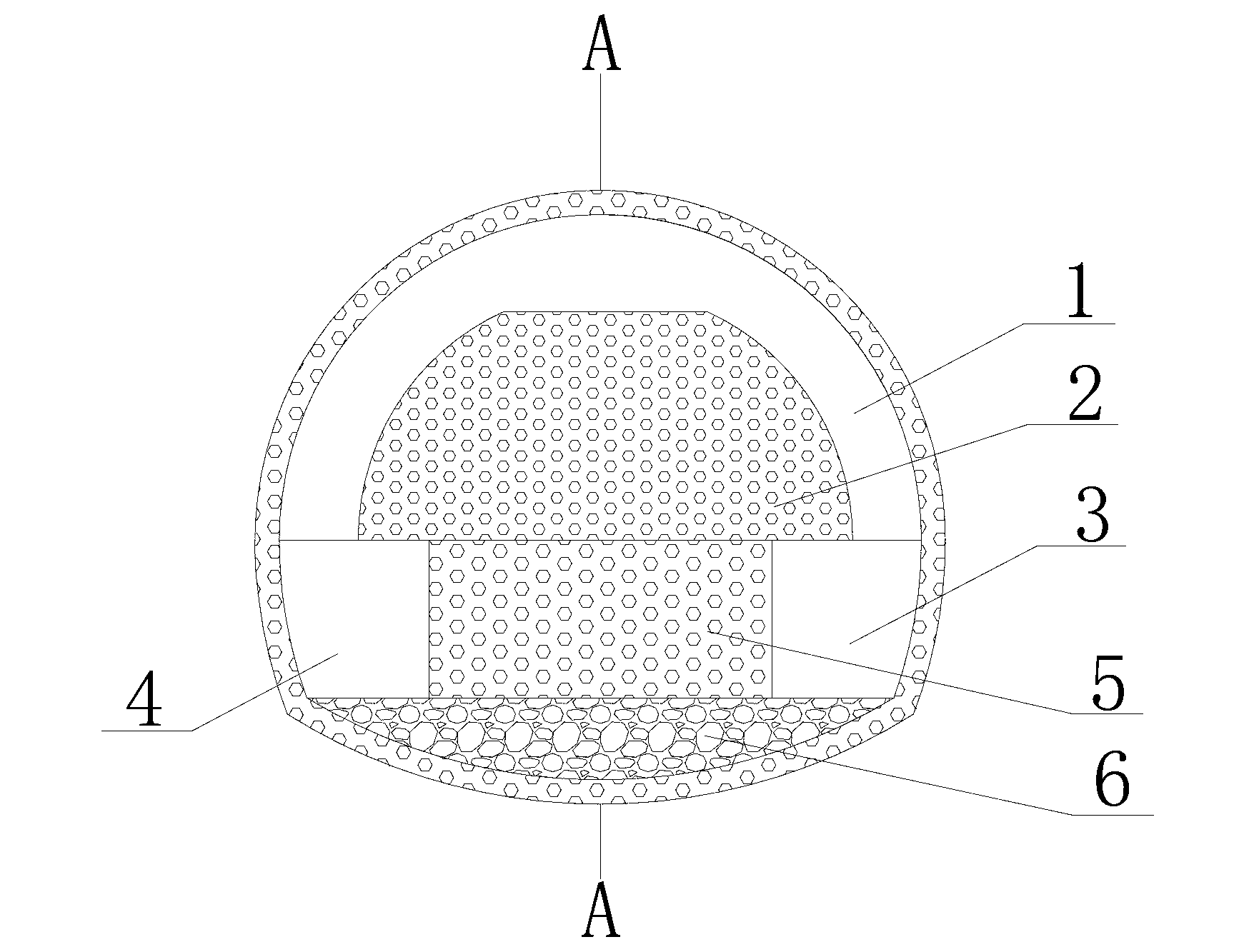

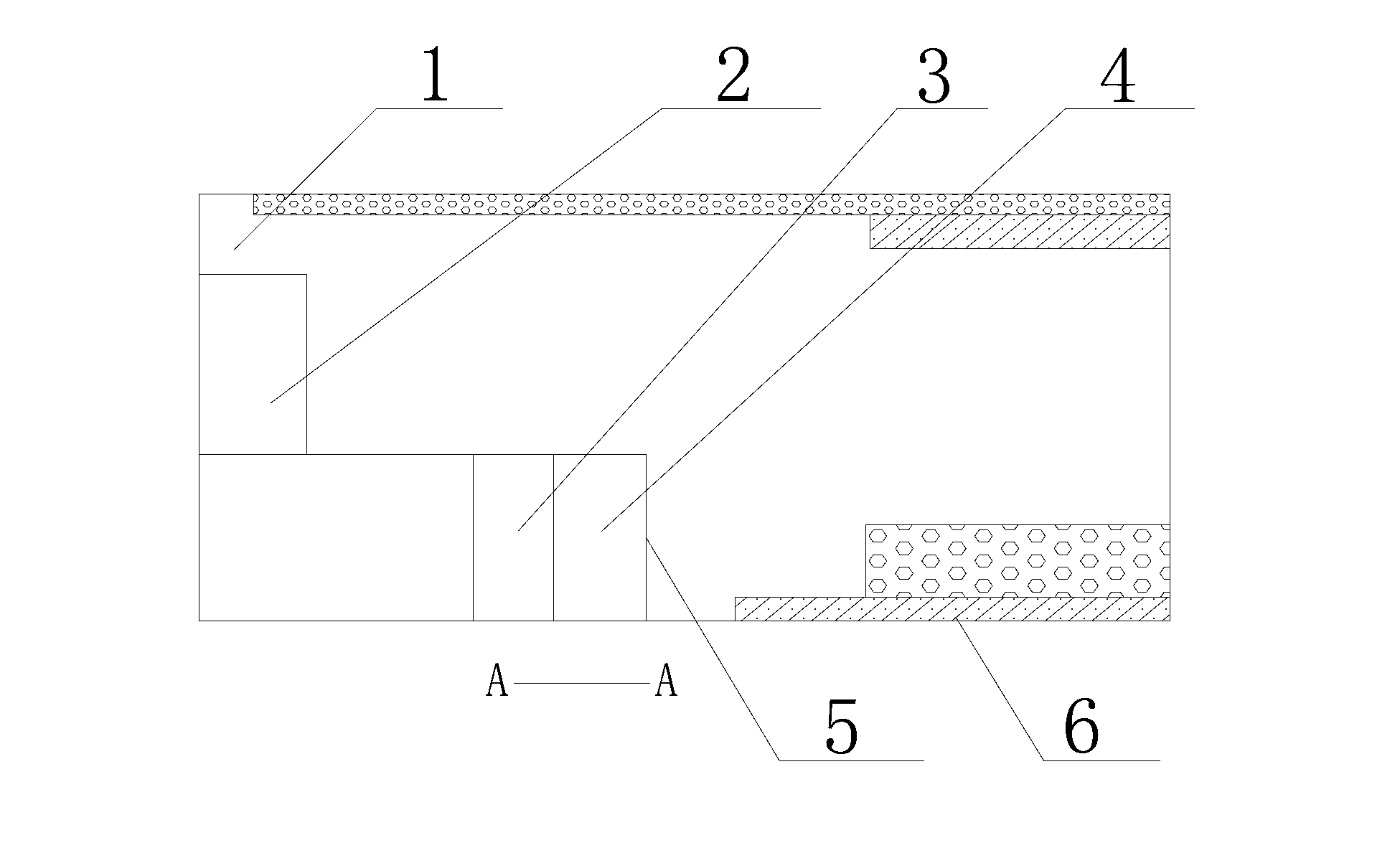

[0023] Embodiment of the present invention: a joint construction method of milling and blasting for tunnels in coal-measure strata, in which the cross-section of the tunnel in coal-measure strata is divided into figure 1 And attached figure 2 Several parts are shown, the upper step arc guide part 1, the upper step core soil part 2, the lower step right side wall part 3, the lower step core soil part 5 and the lower step left side wall part 4, for the construction of each part according to Follow the steps below:

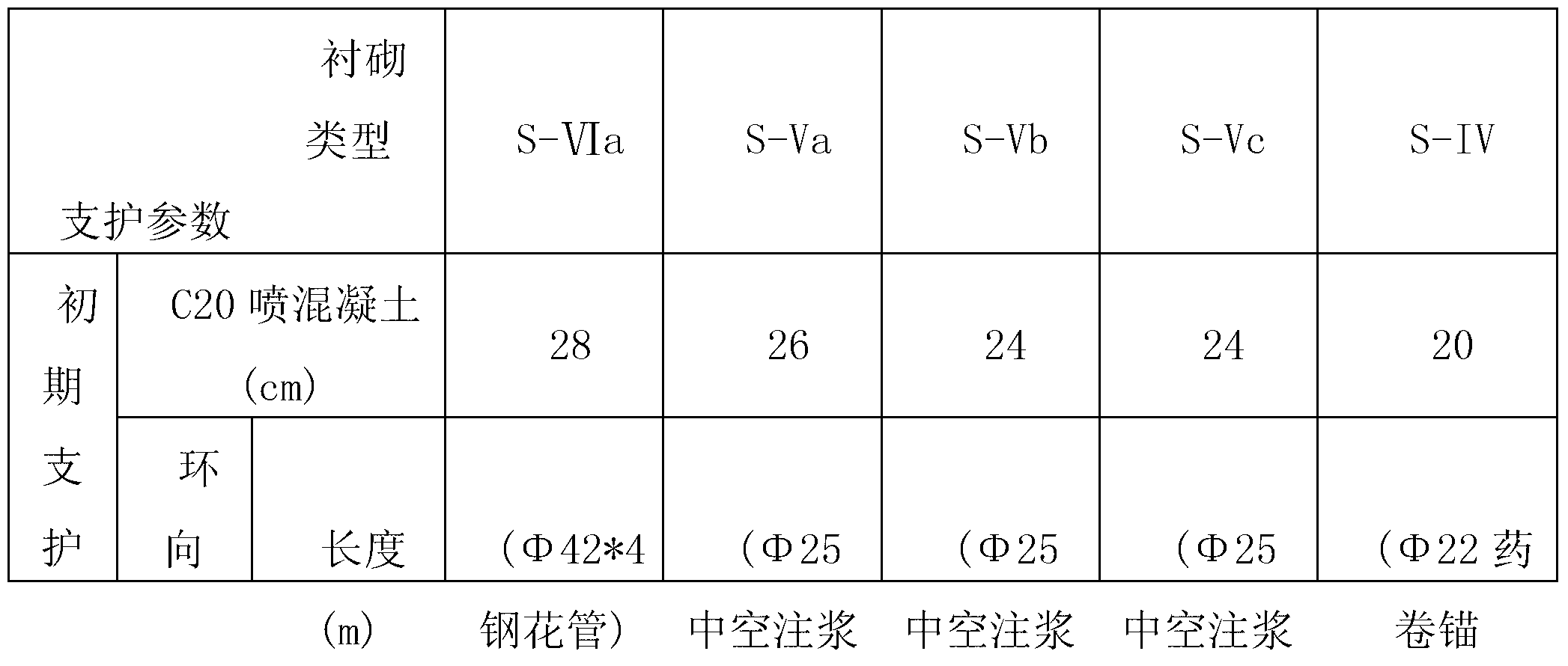

[0024] A. Use the ER100 Eckart milling machine to perform pre-cut grooves on the arc guide part 1 of the upper step starting from the arch feet on both sides of the upper step, and gradually implement pre-cut grooves along the tunnel design contour line to the vault to ensure that the cut groove contour is smooth and smooth. The groove width is 1.5 meters from the excavation contour on both sides, and the arch part is 1.8 meters. According to the needs of construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com