Ultrasonic thickness measurement device and method for multilayered wave-absorbing coatings

A wave-absorbing coating and ultrasonic testing technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., to achieve high measurement accuracy, accurate measurement results, and lightweight equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

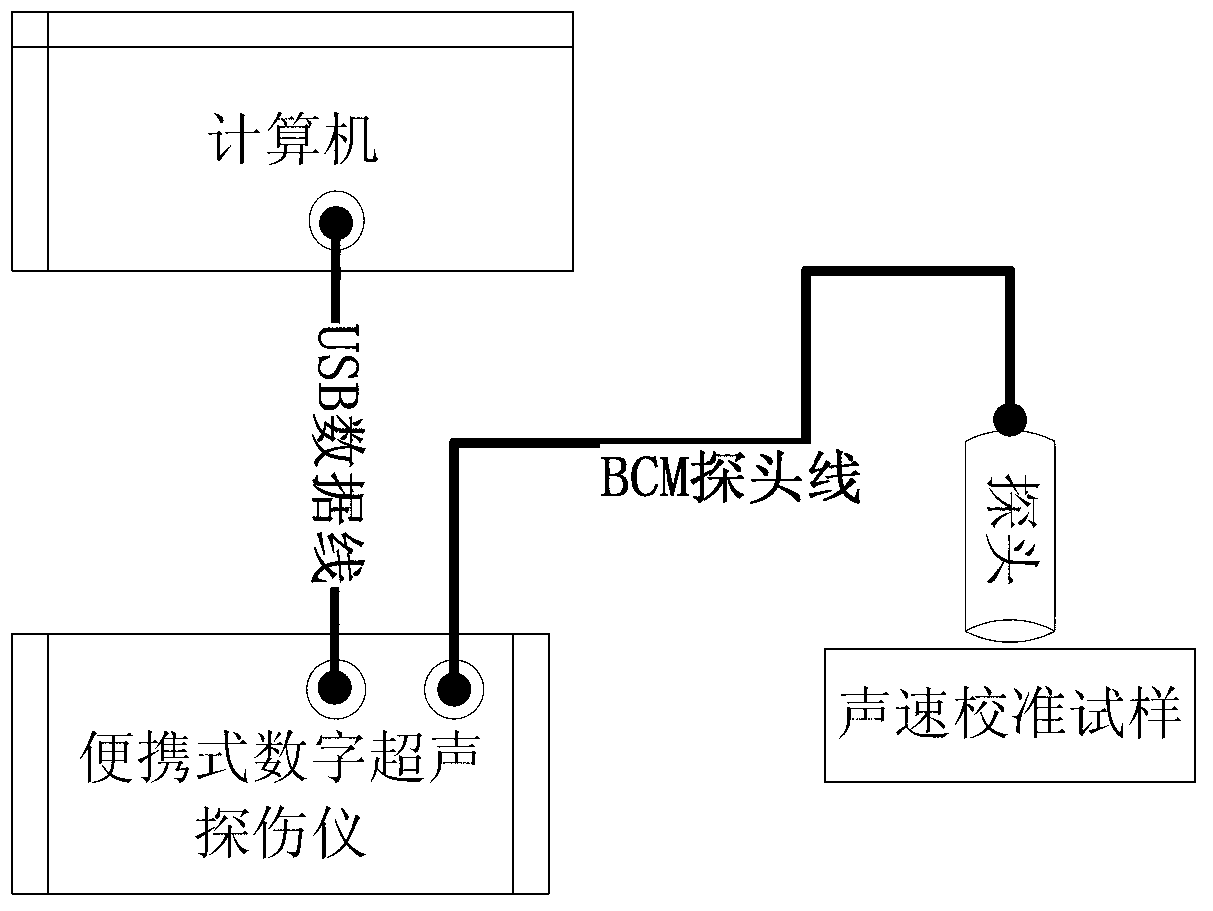

[0031] The thickness measurement device and the thickness measurement method for ultrasonic detection of multilayer absorbing coating figure 1 The shown is a portable digital ultrasonic flaw detector with a bandwidth of 0-35MHz, a delay block probe or a partially immersed ultrasonic delay line probe, a coating sound velocity calibration sample and a computer integrated with a thickness measurement algorithm. It can measure the coating thickness of single-layer, double-layer and three-layer absorbing outer coatings including metal and non-metal substrates. The process of the thickness measurement method is as follows:

[0032] For steel-based wave-absorbing coating samples with a coating thickness ranging from 0.3 to 0.7mm, a delay block probe with a nominal frequency of 15MHz is selected, and the measuring device is first connected to the system and the instrument is calibrated.

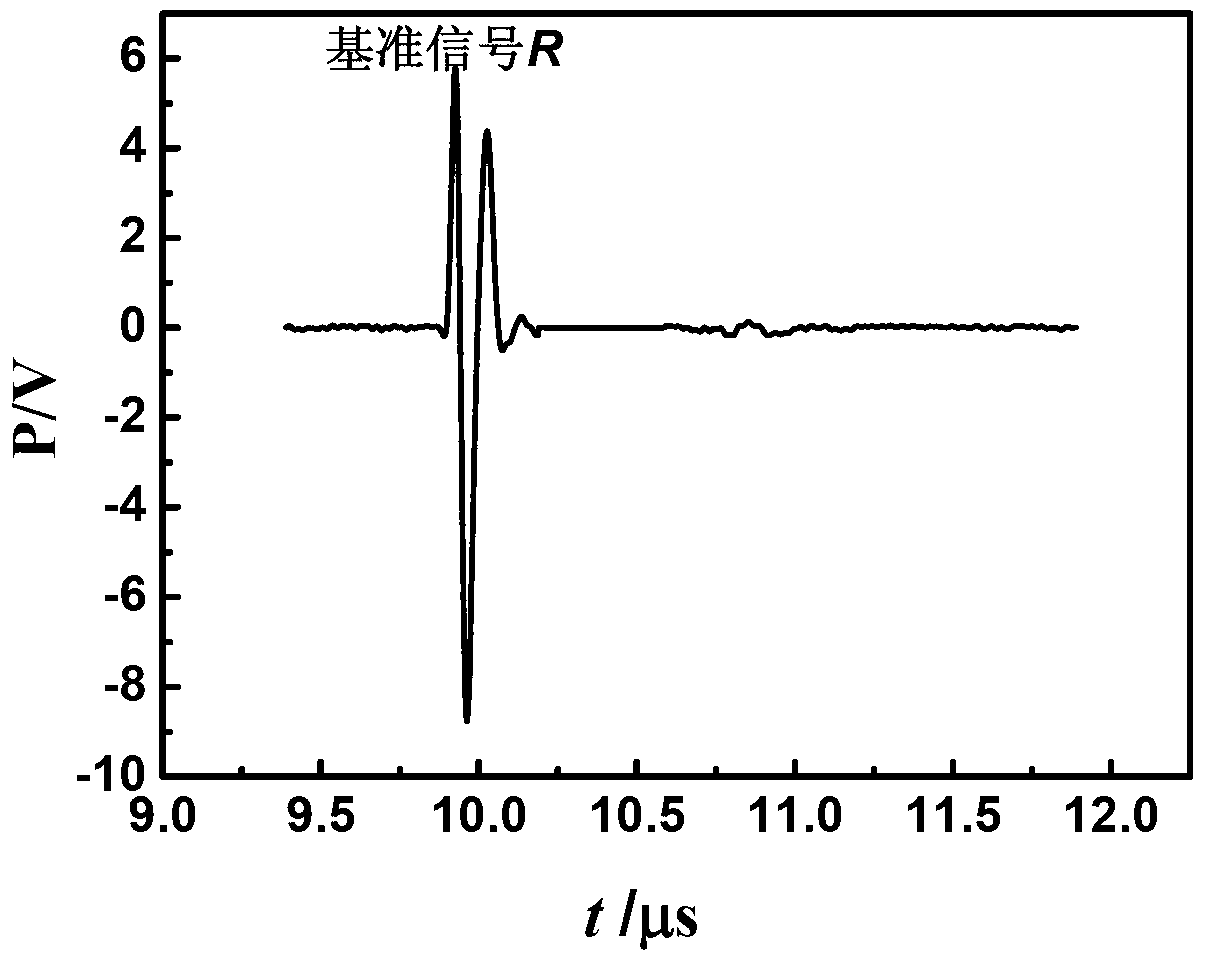

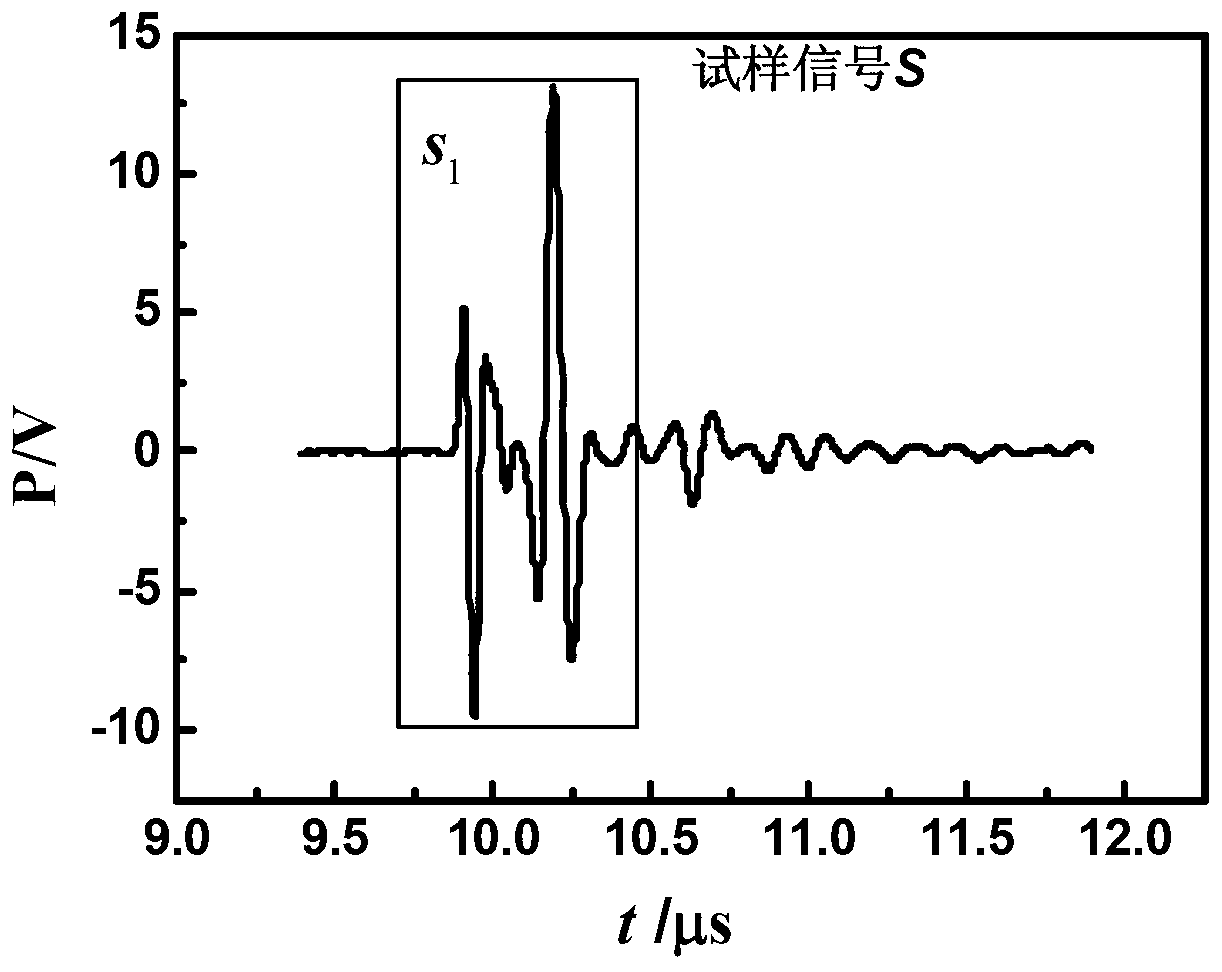

[0033] (1) Collect the reflected echo signal R (reference signal) of the delay block probe, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com